The product range

Professional and versatile

Success by the finest design

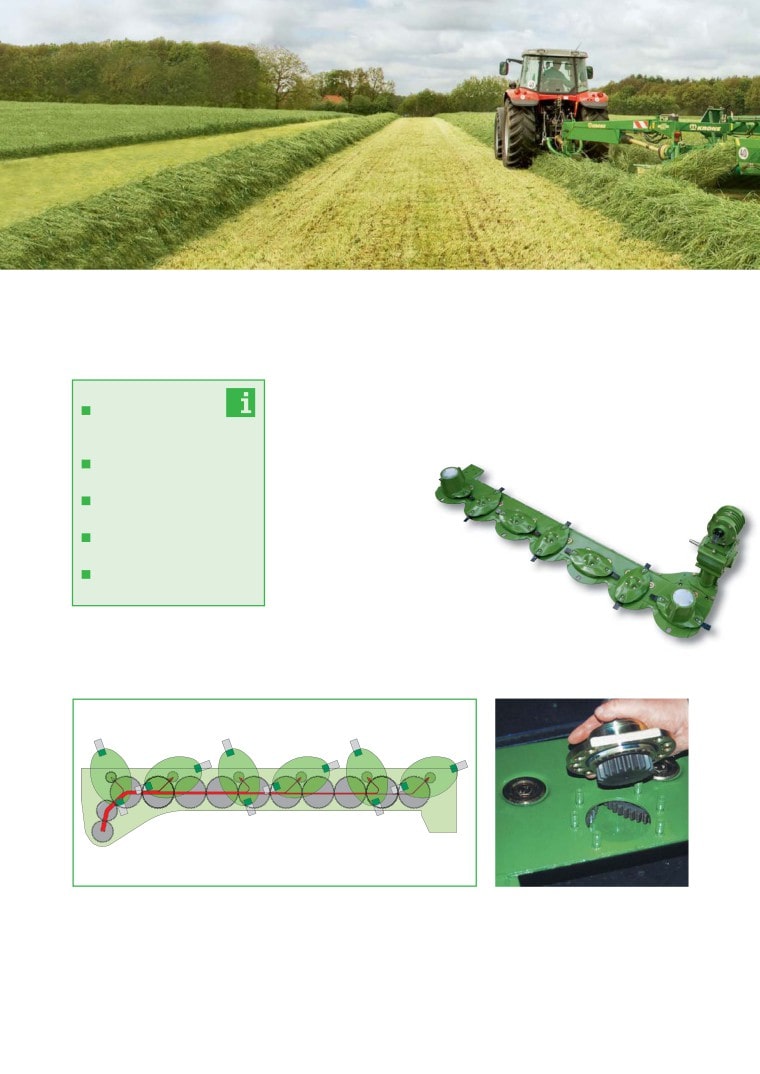

The cutterbar

You can rely on it.

Fully welded and wedge-shaped cutterbars

- design and functionality

CV steel tine conditioner

Total quality forage.

The KRONE high-capacity conditioner with

adjustable baffle plate

CRi roller conditioner

The specialist in Alfalfa

Two rollers, two drive systems - for effective treatment

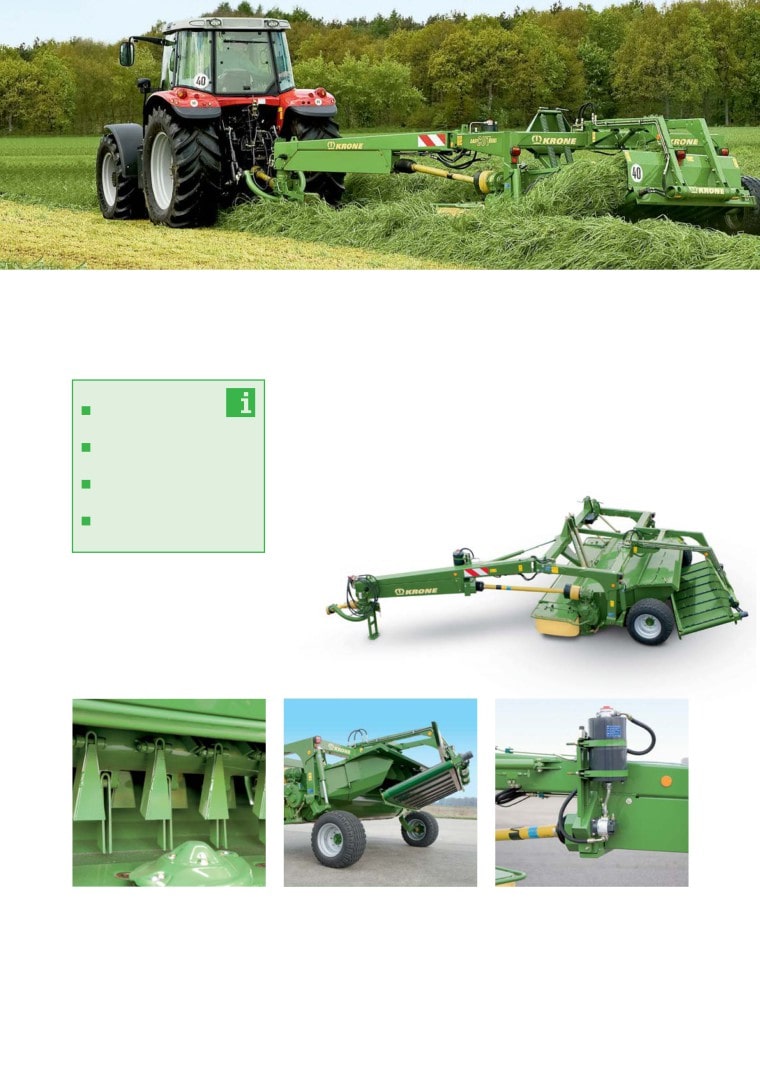

Cross conveyor

Hydraulic swath board control

Gathering two windrows into one,

placing two windrows side by side

Two into one will go!

Save time and cost

KRONE DuoGrip - the side-

control center-of-gravity

suspension system

Cutting at uniform ground pressure across the full

working width

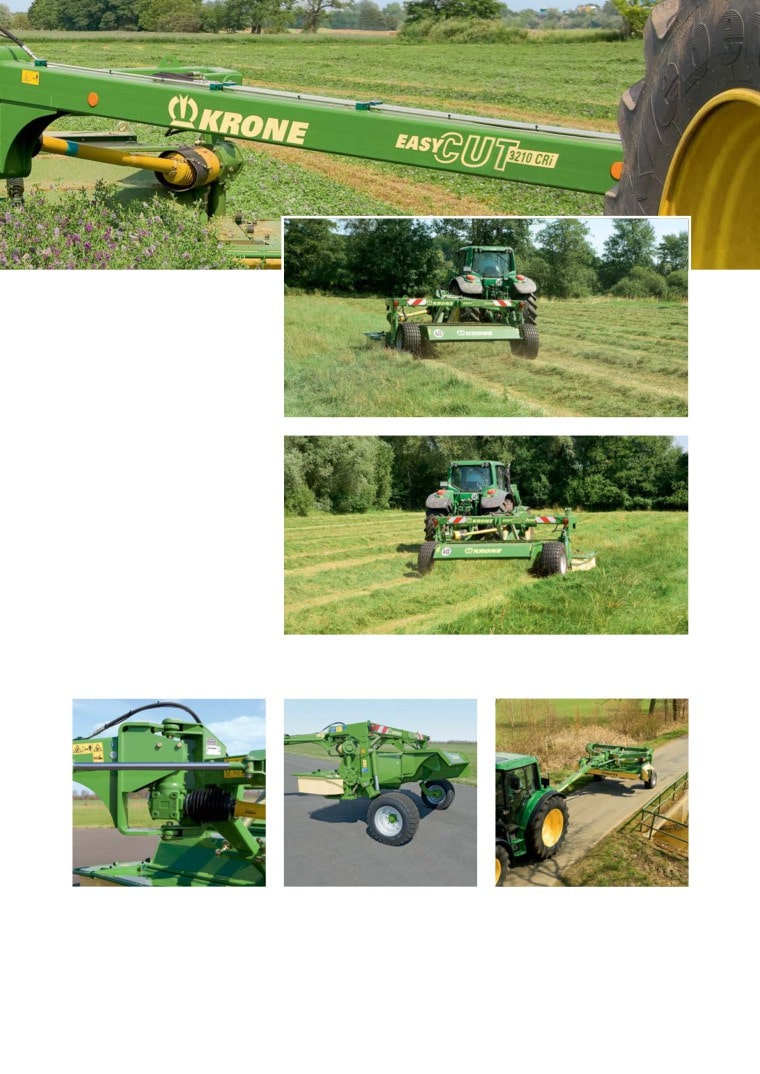

With side-mounted drawbar

with side-mounted drawbar

Compact on the road, agile in the field

With mid-mounted drawbar

Cutting left and right

The mid-mounted drawbar has made it possible

EasyCut 6210 CV

Two high-capacity mower conditioners

in a staggered arrangement offers 6.20 m (20'3")

work widths

Huge area outputs, perfect cuts

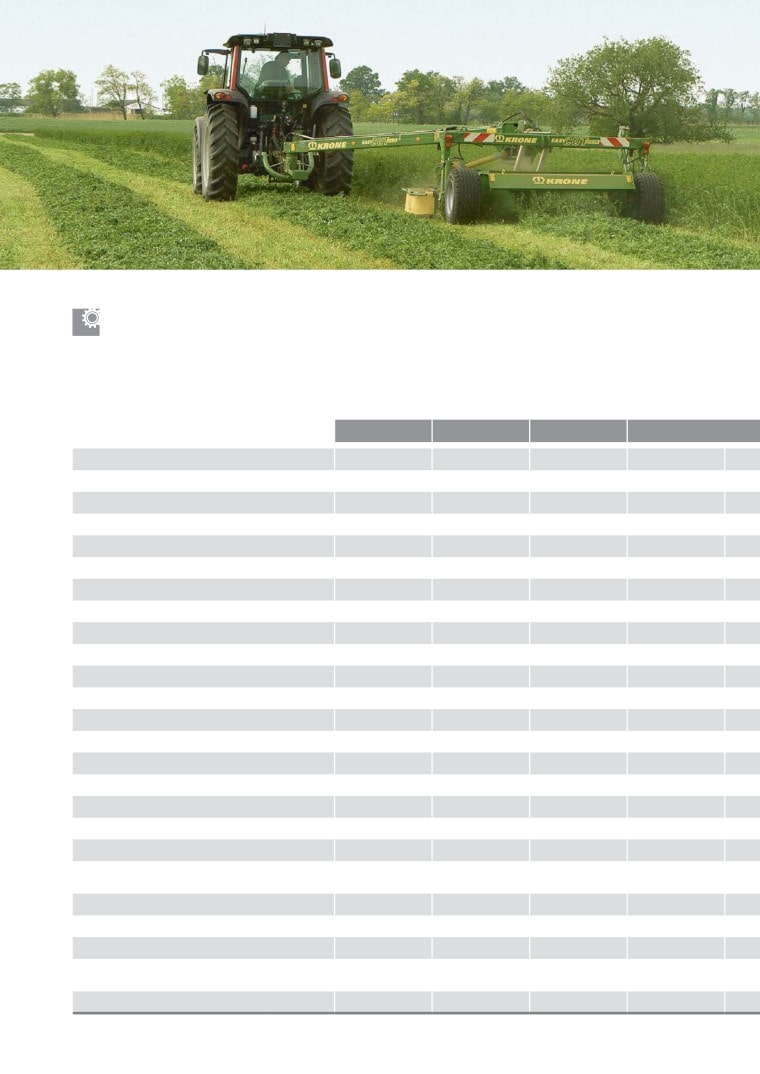

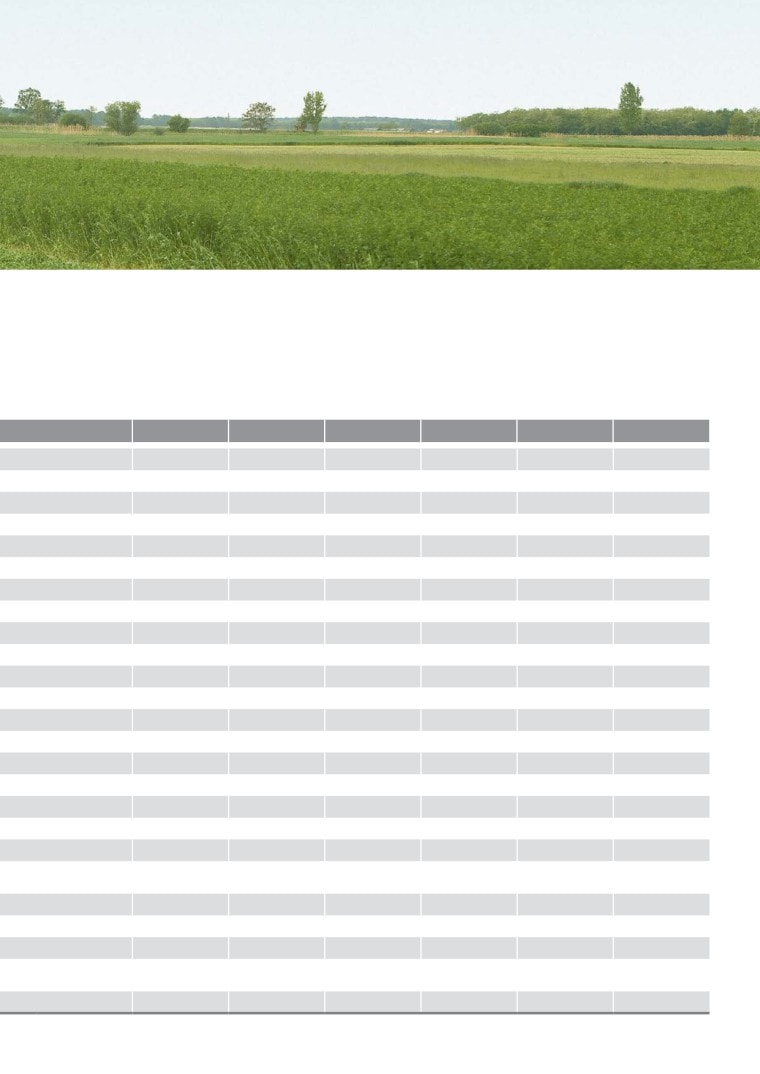

Technical Data

Customer information:

Figures and facts

that speak for themselves

Mowers for professionals -

The trailed EasyCut disc mowers from KRONE

Trailed disc mowers cater to a wide variety of demands

Versatile

and applications depending on country, region and type of

Appropriate

operation. Our extensive range of mower versions offers

Efficient

our customers the choice to pick the specific machine

Profitable

that best suits their specific needs. These include the

V steel tine conditioner with wide-distributing

hood, CRi roller conditioner, cross

conveyor merger and hydraulic

swath board control.

The EasyCut 2801 CV, 3200 CV, 3201 CV,

The EasyCut 3210 CV, 3210 CRi and 4013

The EasyCut 2801 CV, 3200 CV, 3201 CV,

3200 CRi and 3600 CV models with side-

CV models feature a mid-mounted draw-

3210 CV, 3600 CV and 4013 CV models

mounted drawbar work round and round

bar with hydraulic control to swing to the

feature a wide V-steel tine conditioner,

- even in bends and corners - without ever

right or left of the tractor. These are the

where the pivoting V-type tines provide

lifting out of work or reversing.

ideal machines for cutting large fields.

uniform conditioning across the full work

width.

4

Pull-type mower

side drawbar

middle

v-steel tine

Cross conveyor

CRi roller

Hydr. swath board

drawbar

conditioner

merger (option)

conditioner

control (option)

EasyCut 2801 CV

EasyCut 3200

EasyCut 3200 CV

EasyCut 3201 CV

EasyCut 3210 CV

EasyCut 2800 CRi

EasyCut 3200 CRi

EasyCut 3210 CRi

EasyCut 3600 CV

EasyCut 4013 CV

Easycut 6210 CV

EasyCut 2800 CRi, 3200 CRi and 3210 CRi

Two will go into one - EasyCut 3200 CV,

EasyCut

6210 CV

- one mower, two

featuring conditioner rollers. The full-width

3201 CV and 3210 CV are available with

separate cutterbars. This high-capacity

and chevron-profiled rollers interlock and

cross conveyor belt merger, EasyCut 2801

mower with mid-mounted drawbar

deliver superb treatment of legumes and

CV, 3200 CV, 3201 CV and 3210 CV with

produces perfect cuts at a 6.20 m (20'3")

other leafy crops.

hydraulic swath board control to gather

working width.

two windrows into one or placing two

windrows next to each other.

5

EasyCut - a unique KRONE system

The KRONE EasyCut disc mowers provide clean and accurate

The cutterbar -

cuts. The enclosed and fully welded cutterbar operates

permanently lubricated,

dependably and leak-free over many years of hard work.

fully welded and leak-proof

Massive and oil-immersed

Wedge-shaped profile

spur gears guarantee

Clean cutting

quiet and reliable

Extra wide and hardened

running in permanent

flotation skids

operation and highest

No inner shoe

Blockage-free operation

workloads. All EasyCut

Massive spur gears

mowers feature wide flotation

Efficient driveline

skids, which protect both the

cutterbar and the turf. All knives

are standard quick-change.

The satellite gears are a KRONE development, which has proven extremely well all over

Straightforward and effective. Some of the

the world since 1989. Massive spur gears with up to 66 teeth ensure positive mesh and

gears beneath the discs mount eccentri-

efficient power transmission down to the very last disc. The large-diameter gears rotate at

cally in the casing. These are removed from

reduced speed, with more teeth meshing with the neighbouring gears for quieter running,

the top and complete with their bearings;

ultimate efficiency and maximum longevity. The auxiliary gears drive one disc each and

whereas the large gears on the main drive

are therefore exposed to only minimum loading. The discs are arranged in a very forward

system are removed from the side.

position, which ensures the blades overlap generously to produce perfect cuts.

6

EasyCut produces better cuts. Thanks to

its wedge-shaped cutterbar, it cuts short

stubble in meadows and pastures and

slightly longer stubble in long-stemmed

field crops. The wedge-shaped design

provides a larger choice of settings and

therefore more options to deal with diffi-

cult conditions. The advantage for users

is clean cuts and blockage-free operation.

As another KRONE benefit, the massive

spur gears run in double bearings, which

are spaced wide apart to withstand high-

est and permanent loading.

The hardened discs spin in a massive and

thick-walled mower bed, which offers full

protection from any damage - for complete

peace of mind.

The rugged and absolutely leak-free cut-

Smart by design, the cutterbar is powered

Constant pto speed - thanks to a driveline

terbars from KRONE are fully welded by

by a right-angle gearbox, which is arran-

that is comprised of driveshafts and gea-

advanced robot and CNC technologies to

ged right behind the inner top hat - for

rings, which effectively transfer the drive

achieve the highest-quality build. After all,

blockage-free operation on the headland

power to the discs, even when operating in

the cutterbar is the heart of a disc mower.

and in awkwardly shaped fields.

heavy crops and at wide working widths. The

main gearbox on all trailed EasyCut mowers

matches a 1,000 rpm pto as standard fit.

7

EasyCut - clean and effective cuts

The wedge-shaped EasyCut cutterbar was developed over

Standard quick-change

decades of mower manufacturing. The success of all KRONE

blades

disc mowers is based on their perfect performance, unmatched

Replaceable knife attachment

longevity and a host of unique selling points. EasyCut mowers

pins and wear parts

deliver to customers needs. Quick change blades, the satellite

Full 360° knife rotation

driveline and the SafeCut shear-off system

Each SafeCut disc is

on the individual discs are only some

shear-bolt protected

of the benefits of EasyCut

disc mowers.

Worn knife pins and wear parts are not

Floating over the turf, extremely wide skids

Excellent cuts

-

112 mm (4.4") knives

an issue on KRONE EasyCut. They are

made from hardened steel are bolted to

mount on their individual discs in alternate

designed to be replaced in pairs. The pins

the cutterbar to protect the unit and the

arrangements, giving generous overlap.

may be substituted with threaded bolts

turf. High-cutting skids are available to

Impact stops are welded between the

upon request.

produce longer than 80 mm (3") stubble.

skids to protect the cutterbar from damage

Depending on the installation, these skids

and deliver an excellent cut.

increase the cutting height by 30 mm (1")

or 50 mm (2").

8

SafeCut: The new and standard impact

disc protection system offers a unique le-

vel of protection and functionality.

The situation is familiar to every farmer -

a disc collides with a stone, is damaged

and requires repair. Offering maximum

protection, the KRONE SafeCut system

does not transfer the full load of the impact

to the spur gears. Instead, the roll pin in

the sprocket driveshaft breaks when there

is a momentary overload. The pinion shaft

continues spinning, jacking up the disc in

question and moving it out of the risk zone

and the orbit of the neighbouring discs to

avoid damaging these as well.

Unlimited spin - the knives are free to spin

The ideal design - there is no load on the

The moment of impact: The roll pin breaks,

through 360°. They are hard-wearing and

roll pins during operation. The bearing

the disc jacks 15 mm (0.6") up on the shaft

self-cleaning, well protected and will not

is tensioned by a nut and two clamping

threading and stops spinning actively,

interfere with the knives on the neighbou-

screws. As a result, the roll pins cannot

Eliminating the risk of colliding with the

ring discs.

suffer from material fatigue and continue

neighbouring discs and damaging these.

breaking at the inbuilt loading level after

many hours of operation.

9

CV steel tine conditioner

Pivoting V-tines produce high-quality forage

Efficiency is one criteria in hay and forage harvesting, quality is

Massive 640 mm (2')

another. The high-capacity KRONE CV mower conditioner with

tine rotor

V-type steel tines conditions the crop uniformly and across the

Freely pivoting steel tines for

full working width to promote wilting, reduce field traffic and

absolute peace of mind

produce top-quality forage.

Steplessly adjustable baffle

plate

Mechanical 600 rpm and

900 rpm gearbox

Adjustable wide-distributing

hood

64 cm

Cutterbar and conditioner share the same

Heavy duty. EasyCut 3201 CV and 3600

High efficiency for high quality. The

gearbox, which also integrates the two-

CV feature an extremely heavy-duty drive-

massive conditioner rotor with V-shaped

speed mechanical CV conditioner gearbox

line to the cutterbar and conditioner rotor.

steel tines is 64 cm (2') in diameter and

(600 rpm and 900 rpm).

To keep the oil temperatures low, we also

impresses by highest throughputs and

installed cooling fins to ensure dependable

best conditioning results. The intensity of

operation in the heaviest crops.

conditioning is controlled by the infinitely

adjustable baffle plate.

10

Wide spreading or narrow windrows

-

scientific research has shown that wide

spreading enhances significantly fermen-

tation and forage quality. Accordingly, the

hood not only spreads the material over

a large area, but also produces light and

fluffy windrows, which in turn eliminate at

least one tedding pass and lead to higher

milk production while reducing the require-

ment for feed additives.

Full-width conditioning. Specified with V-type steel tines and baffle plate, the conditioner

Full flexibility: The optional guide plates

spans the entire work width, provides a uniform crop flow across the full width and of

feature a pin/hole setting system to vary

course optimum conditioning. In addition, guide plates deflect the material flow for sprea-

the angle. Choose between narrow wind-

ding across the full width for rapid wilting.

rowing in wet and boggy terrain and wide

spreading, if rapid drying is the priority.

11

CRi roller conditioner

The specialist in Alfalfa

Delicate and broad-leaved crops such as Alfalfa are conditioned

CRi roller conditioner

best by the interlocking KRONE CRi conditioner rollers. Profiled

The specialist in Alfalfa

in a chevron pattern, this conditioner is typically operated in

25 cm (10") diameter rotor

Alfalfa to provide gentle treatment to the delicate leaves while

for smooth crop flow

crimping the stems to ensure faster and more uniform wilting.

Polyurethane coating for

long service life

Separate roller drives for

high throughputs

Chevron profiled rollers give

positive crop treatment

Full-width conditioning. The full-width CRi rollers ensure uniform conditioning across the

250 mm (10") diameter CRi rollers ensure a

entire work width. Thanks to a stepless adjustment system, the operator easily adapts

smooth and unobstructed crop flow while

the roller clearance and pressure to the current crop yield and variety. The polyurethane

reducing required tractor power.

coating gives lasting resistance to abrasion and wear.

12

Legumes and herbs require a different type

of conditioning than crops that are predo-

minantly grass. Providing gentle treatment

to leafy crops, the CRi roller conditioner

leads to less fragmentation than a tined

rotor, leaving the delicate leaves intact,

which are so rich in valuable protein,

and preserve the quality of farm-grown

feedstuff. Spreading the crops wide, the

system also makes for faster wilting. This

optional CRi conditioner version comple-

ments the KRONE range of mowers to

meet all farming needs.

Hungry - the large-diameter and chevron-

Frictional connections - drive power to the

Two rollers, two gearboxes. The top roller

profiled conditioner rollers interlock to

roller conditioner flows directly and slip-

is driven by a separate gearbox on the right

crimp, rub and crush the crop at great in-

free via gearboxes. The gears that drive

end of the cutterbar and is synchronized

tensity.

the bottom roller are integrated in the cut-

with the bottom roller.

terbar gearbox behind the left top hat.

13

The cross conveyor merger is an option

Two will go into one!

Combining three passes into one single pass, the trailed

Separate hydraulic

EasyCut 3200 CV, 3201 CV, 3200 CRi, 3210 CV and 3600 CV

drive

models cut, condition and windrow the crop in one single

Infinitely variable spreading

operation, thanks to the hydraulic driven cross conveyor belt

width

merger. These models save your time, increase your efficiency,

Conveyor shuts automatically

reduce the number of passes and the

on/off during lower/lift

risk of soil compaction and

Conditioner tray enhances

produce clean forage.

the crop flow

On machines specified with a cross conve-

Losses are not accepted. All cross con-

The cross conveyor belt merger in com-

yor belt merger, the V-type steel tines not

veyor belt versions of trailed EasyCut CV

bination with CRi conditioner rollers is the

only condition the material but feed it to

disc mowers feature a steel tray beneath

ideal combination in Alfalfa when this is

the belt. Therefore, some of the tines are

the V-steel tine conditioner, which collects

harvested without turning or windrowing.

solid metal to enhance the efficiency of

every single haulm for conveying it into the

The material drops from the rollers onto

their throw.

windrow.

the conveyor, which feeds it out to the side

without losses.

14

The trailed EasyCut disc mower condi-

tioners with cross conveyor belt suit a

wide range of applications. Being true

all-round machines, they produce wide

and compact single windrows or convey

the material onto the existing windrow or

next to it to form a double windrow that

is easily picked up by the following har-

vester. Feeding the crop onto the windrow

without the material ever touching ground,

the cross conveyor ensures clean forage

without losses.

A blockage-free system, the 900 mm (3') belt boasts weld-on feed bars that provide for

Powerful hydromotor and infinitely variable

constant crop flows and fast cutting in heavy crops as well as forming uniform windrows for

conveyor speed - the perfect match to set

excellent presentation to the pick-up on the following harvester. Separate hydraulic system:

windrow widths to requirement for the

Oil supply to the cross conveyor comes from a separate oil reservoir rather than the tractor’s

following harvester.

hydraulic system.

The motor shuts off automatically as the

belt lifts out and is restarted automatically

when the belt lowers back into work.

15

The EasyCut 32 CV and 32 CRi combi-

nation produces a double windrow in a

single operation. The cross conveyor belt

merger places the material onto or next to

the windrow that is produced by the front

mower. Eliminating the tedder and rake

passes, the combination boosts your ef-

ficiency and saves your time and money.

These facts suggest that gathering two

windrows into one is a profitable strategy

that justifies the investment of a cross con-

veyor belt merger.

Strong beams suspend the cross conveyor

An ideal system, a single-acting ram raises

Operator comfort - the operator changes

belt for ultimate stability when operating

the cross conveyor as a reversing valve

belt speed conveniently from the cab by

in heavy crops, uneven fields and on the

shuts it off and back on when the ram

operating a rotary potentiometer, which

slope. They swing the unit up and out of

lowers the unit back into work.

controls the throw and placement of the

work when the mower is producing single

crop on top of the existing windrow or next

or wide windrows.

to it.

16

A new and competitive approach to

windrowing - the trailed EasyCut

2801

CV, 3200 CV and 3201 CV disc mowers

are available with long, hydraulic control

swath boards, which tighten the crop flow

and windrow the material to the right or

to the left depending on the current an-

gle. The double windrows produced by

EasyCut 2801 CV are easy to ingest by

the 3.00 m (9'10") pick-up on a SF forage

harvester like KRONE BiG X. EasyCut

3200 CV, 3201 CV and 3210 CV produce

double windrows that feed a

3.80 m

(12'6") SF pick-up.

Forming perfect double windrows, the

Providing infinite variable adjustment,

The swath boards turn to the left or right,

long and pivoting swath boards tighten the

the two swath boards are controlled by

the drawbar swings in or out into work or

material flow and windrow it neatly to the

a shared linkage system and a double-

transport position. The operator selects

side, forming fluffy double windrows for

acting ram that synchronizes action to the

the individual functions on the electric

easy pick up by the harvester.

right or left.

control box.

17

DuoGrip

The intelligent linkage system - a unique KRONE design

At the heart of high-quality forage is a perfect and clean cut,

Trailed mower

which in turn is down to the specific design of the mower

suspended in a double frame

and its suspension and control system. KRONE DuoGrip not

DuoGrip: Center-of-gravity

only suspends the mower in its center of gravity but guides

suspension system

the machine on either side of the mower. The speciality of the

Added side control

system is that it maintains the ground pressure

Uniform ground pressure

across the full work width and provides

across the entire work width

highest stability and

Quick-response tension

springs for accurate contour

optimum side control.

following

Stepless ground pressure

adjusting system

Adjust the ground pressure conveniently

A well-balanced mower that suspends and

DuoGrip - parallel linkages distribute the

to requirements. Adjustable coil springs

trails in its center of gravity will achieve

load on the machine. Suspended in its

provide quick and optimum adaptation

better-quality cuts. The DuoGrip system

center of gravity, the mower receives addi-

to all conditions. The system stands out

ensures the machine pulls with ease, pro-

tional control by a linkage system on either

for its large choice of setting options and

tecting the valuable turf without contami-

side of the machine. This DuoGrip system

convenient handling.

nating the crop while maintaining the pres-

absorbs any lateral loading on the machi-

sure across the full width.

ne, reduces the loading on the center-of-

gravity suspension system and adds to the

rugged design of the mower.

18

DuoGrip is a two-point linkage system,

which suspends the trailed mower con-

ditioner in a double frame. DuoGrip com-

bines ultimate stability at low weight and

positive side control while mounting the

mower exactly in its center of gravity.

The advantages are clean cuts, optimum

ground adaptation in uneven terrain,

superior longevity, easy pulling, reduced

side pull and better fuel efficiency. The

trailed EasyCut mowers bring efficiency

to your operation and harvests, producing

top-level forage quality and protecting

your valuable turf.

Quick and easy. This crank controls the

Adaptive - the mower pivots in a double

There is plenty of pivoting room on either

cutting height. EasyCut

2801 CV and

frame for full up/down travel to avoid ob-

end of the cutterbar, which allows the unit

EasyCut 3201 CV may be specified with

stacles and follow ground undulations. The

to adapt to any ground contours. As the

an optional hydraulic ram, which tilts the

system’s response is controlled by spring

mower pivots in its double frame, it closely

mower as it crosses tramlines and runs

tension. The stronger the tension of the

follows the ground - to the effect of produ-

through hollows.

springs, the more responsive the system is.

cing clean forage and protecting the turf.

19

With side-mounted drawbar and no conditioner

EasyCut 3200

Are you looking for a powerful trailed mower without conditioner

Pulls with ease

that works at a width of about 3.00 m (9'10")? Then the KRONE

Ideal behind low-horsepower

EasyCut 3200 with DuoGrip center-of-gravity suspension is the

tractors

machine for you. This mower stands out for an extremely low

compact and easy-pulling as

power input, maximum stability as well as a superior level of

it takes load off the rear axle

specification and operator comfort.

Swivel gearbox for round and

round work

Turns on the spot

DuoGrip center-of-gravity

suspension

Strong V-frame

Depth control is convenient

from a crank

Appropriate. The V-shaped frame on the EasyCut 3200 model with side-mounted drawbar

Cutting at the optimum height. The cutting

is robust, compact and yet high enough to give the mower plenty of travel. Suspended

height is adjusted on a threaded spindle

in its center of gravity, guided by side arms and benefitting from the high frame, the

and it takes just a minute to adjust the ma-

cutterbar swings back and up through a large angle to avoid obstacles, leaving a clean

chine perfectly to the current conditions.

surface even in undulating terrain and ensuring not a haulm is lost. The drive power flows

The cutterbar’s ground pressure is adju-

down driveshafts and through a massive right-angle gearbox, which is arranged behind

sted by tensioning the coil springs.

the inner top hat.

20

The powerful, easy pulling and innovative

trailed EasyCut 3200 model without con-

ditioner offers the unique SafeCut impact

protection system and amazing operator

comfort also when operated by a lower-

powered tractor. Unlike the mounted

version, the trailed version does not tap

into the tractor hydraulics and does not

shift weight to the rear axle. Its transport

height is much lower. All these attributes

make the machine safer when operating

on slopes and when managing turns at

speed. Offering a transport width of 3.00 m

(9'10"), EasyCut

3200 can travel on all

public roads.

Maneuverable. Equipped with side-moun-

Easy to maintain: The front section of the

Nice and compact. Running inline behind

ted drawbar and pivoting gearbox, the unit

frame folds up to give easy access to the

the tractor, EasyCut 3200 does not exceed

cuts around any bend. The two-point head-

discs for cleaning and convenient blade

the statutory

3.00 m

(9'10") transport

stock attaches to the height-adjustable link

replacement.

width, gives plenty of ground clearance

arms - although the floating drawbar has

and is approved to 40 km/h (25 mph)

become the preferred choice of attachment

maximum speed. This is the machine to

in some countries.

travel quickly between sites.

21

With side-mounted drawbar and conditioner

EasyCut 2801 CV, 2800 CRi, 3200 CV, 3201 CV, 3200 CRi, 3600 CV

The trailed and powerful EasyCut disc mowers with side-mounted

Compact design

drawbar have proven extraordinarily well all over the world.

Extremely agile

Compact by design, these machines feature a strong double

More than 90° turn angle

frame and a side-mounted drawbar for mowing round and round.

Ideal in round and round

These mowers are a revelation of advanced mower technology.

operations.

Turns on the spot

Center-of-gravity suspension

DuoGrip

EasyCut 3600 CV: approx.

3.40 m (11'2") transport width

Mowing round and round without ever

Thanks to the pivoting gearbox, the main

Sure footed - as the machines operate

stopping, the trailed EasyCut mower with

driveshaft will not angle when travelling

on soft ground and slopes, they run on

side-mounted drawbar cuts around every

through bends to the benefit of an exten-

15.0/55-17/10 tires that provide light trea-

corner and turns on the spot thanks to the

ded service life. In addition, the torque of

ding to protect the turf. Mounted at a 3°

pivoting gearbox and the short drawbar,

the swivel gearbox helps absorb the side-

angle, the wheels effectively roll in direc-

eliminating the need to reverse into cor-

thrust and ensures quiet running and posi-

tion of travel without pulling to the side.

ners.

tive tracking.

22

Harvest at maximum rates - when opening

up a field, turning on the headland or

cutting around bends, corners and in

angles. The trailed EasyCut disc mower

with side-mounted drawbar and swivel

gearbox gives you the flexibility of mowing

round and round without lifting the ma-

chine out of work, without reversing and

without ever stopping. Thanks to the short

drawbar, these disc mowers are extremely

compact and pull easily. Also, they have

proven exceptionally effective in small

fields and stand out for superb tracking.

KRONE disc mowers always run on the

right side and are always cutting edge.

Convenient and fast - the operator pivots

Plenty of ground clearance - single-acting

Swift

40 km/h (25 mph) road transport.

the mower hydraulically into work or trans-

rams raise the double frame and the mo-

Not exceeding the statutory 3.00 m (9'10")

port position from the comfort of his seat.

wer for road transport and when crossing

transport width, EasyCut

2800 CV / CRi,

The swivel ram mounts in a number of dif-

windrows. A tap locks the rams during

3200 CV / CRi and 3201 CV do not require

ferent positions, which enable the operator

road transport.

special permission to travel on public roads.

to utilize the full track width of the pulling

tractor.

23

With mid-mounted drawbar and conditioner

EasyCut 3210 CV, 3210 CRi, 4013 CV

EasyCut 3210 CV, 3210 CRi and 4013 CV are the ideal machines

Cutting to the left

for up and down operation. These high-capacity trailed disc

and right

mowers from KRONE with mid-mounted drawbar cut at widths

Ideal for up and down

of 3.14 m (10'4") and 4.00 m (13'2"). The drawbar is attached

operation

centrally for up and down

Enormous agility thanks to

operation at its best. Both units

swivel gearbox

feature a standard conditioner.

Center-of-gravity suspension

All central drawbar versions

DuoGrip

EasyCut 4013 CV:

feature the full-width CV

3.86 m (12'8") transport width

and CRi conditioners.

Power and efficiency comes from the

Useful - the stand folds down for sure

Changing sides is easy and convenient

swivel gearbox, which allows mowing to

footing. The pto shaft and all oil lines are

from the tractor seat. The double-acting

the left, to the right and continue mow-

stored in convenient holders. The two-

ram swings the mower over to the other

ing while turning. This is the ideal box to

point headstock moves to the side for ea-

side in up and down operation and swings

maximize your efficiency. The distance

sier attachment to the tractor.

it centrally behind the tractor in transport

between tractor and gearbox is always the

position.

same for extended driveshaft service life.

24

The pull-type EasyCut EasyCut 3210 CV

or CRi disc mowers have proven extreme-

ly well in fields around the world - both as

solo machines and in combination with a

front mower. The mid-mounted pivoting

drawbar allows mowing up and down the

field in either direction.

You start on one end of the field and work

down to the opposite end, a method that

will harvest forage of uniform dry matter

contents and quality. There is no need of

harvesting in beds and besides the full

working width is exploited, also when ope-

rating in combination with a front-mounted

mower. In addition, working up and down

allows deer to escape.

Frictional connections without belts ensu-

Swift - the mower lifts out and swivels hy-

Travelling between fields at 40 km/h (25

re that drive power flows smoothly to the

draulically into the middle for transport on

mph). In inline position, EasyCut 3210 CV

cutterbar and conditioner via gearboxes

public roads, a position that gives plenty

and CRi are allowed to run on public roads

and driveshafts - thanks to two swivel

of ground clearance to run over deep ruts

and at 3.00 m (9'10") transport width they

gearboxes. Peace of mind comes from

and windrows.

do not require a special permission.

overload protection built into the driveline.

25

Ultimate efficiency - two mower conditioners in one machine

EasyCut 6210 CV

Its 6.20 m (20'3“") working width

The middle drawbar

and the central drawbar

swings the mower to either

make EasyCut 6210 CV

side

one of the most effective

Swivel gearbox

trailed mowers on the

Enormous swivel range

market. These machines

Two cutterbars

stand out for superior efficiency,

Excellent contour following

maximum stability as well as an advanced

CV steel tine conditioner

Two speeds: 600 / 900 rpm

level of specification and operator comfort.

Adjustable

The CV high-capacity conditioner produces

wide-distributing hoods

best quality forage.

Excellent ground following

- thanks to

A clean cut - the offset cutterbars and

DuoGrip - system that has each mower

two staggered cutterbars rather than one

overlapping blades give cleanest cuts

pivot in its center of gravity and trail in

full-width cutterbar. The two units operate

both in uneven terrain and when travelling

the double frame. The ground pressure

independently of each other and follow

around bends.

is maintained across the full work width

every ground contour. EasyCut 6210 CV

and is controlled by adjusting the tension

is the machine to produce quality forage.

springs on the pivoting arm.

26

Take the choice - EasyCut 6210 CV cuts

to the right or left of the tractor. Simp-

ly swing the drawbar to the other side

as you do the headland turn and match

up with the previous pass without mow-

ing in beds. The tractor is not running in

standing crop so that clean and loss-free

cuts are guaranteed. You always use the

machine to potential and, in combination

with a front-mounted mower, at full width

capacity. In sloping fields, it allows the

tractor to run always on the hillside.

Height control is quick and convenient -

Top-quality forage

- the high-capacity

Swing left, swing right - the mid-mounted

thanks to crank handles that set the

conditioner rotor with pivoting V-steel tines

drawbar swings hydraulically to either

cutting height steplessly and separately on

and mechanical gearbox condition the

side of the tractor. Its double acting ram

each unit.

forage across the full work width and at

is dependable even in the most difficult

600 rpm or 900 rpm. Optional deflectors

conditions.

direct the material flow for full-width

spreading and rapid drying.

27

Ultimate perfection

EasyCut 6210 CV

EasyCut 6210 CV, the disc mower that delivers technology,

Center-of-gravity

functionality, smooth handling and ultimate convenience. This is

suspension DuoGrip

the machine for high-power standard tractors, which has starred

Stepless ground pressure

in contracting applications. Featuring a strong double frame,

adjustment

the powerful mower conditioner running on wide tires is the

Crank-controlled work height

equipment that delivers in unusually demanding

Quick-change blades

applications.

are standard-fit

Large 500/45-22.5 tires

for cutting

Turns on the spot

- the swivel-head

Direct driveline - the position of the gear-

Light treading and easy pulling

- the

gearbox

(1,000 rpm) on the two-point

boxes on the machine allows using short

EasyCut 6210 CV models run on oversized

headstock provides the flexibility to turn

driveshafts. As a result, the driveline is

wheels and 500/45-22.5 tires in standard

through 90° and larger angles while the

vibration-free and there is nearly no wear

configuration. These have proven best in

main driveshaft does not move, allowing

at all.

soft terrain.

drive power to flow vibration-free to the

cutterbar.

28

Time is money. It is not only efficiency that

counts for contractors but also the time

spent in road transport. EasyCut 6210 CV

is a swift road machine that travels at

40 km/h (25 mph). The robust running gear

with air brake system and the large-dia-

meter wheels translate into excellent road

safety and operator comfort. The large

warning panels and road lights provide

safety at dawn and at night.

Wide work widths or narrow transport

need to leave the tractor. It does not take a

and running on 15.0/55-17 tires, this high-

widths - it takes just a few seconds to

sophisticated system to control the semi-

capacity mower provides for superior rides

swing the machine from work into trans-

mounted chassis and its hydraulic ram.

and requires not special permits for public

port position and vice versa. There is no

At a

2.99-metre

(9'10") transport width

roads.

29

Technical data

Trailed disc mowers

EasyCut 2801 CV

EasyCut 2800 CRi

EasyCut 3200

EasyCut 3200 CV

Drawbar version

side-mount

side-mount

side-mount

side-mount

Work width

approx. mm

2,710 (8'11")

2,710 (8'11")

3,140 (10'4")

3,140 (10'4")

Transport width

approx. mm

2,565 (8'5")

2,565 (8'5")

3,000 (9'10")

3,000 (9'10")

No. of discs

4

4

5

5

No. of top hats

2

2

2

2

SafeCut

Standard

Standard

Standard

Standard

Quick-change blades

Standard

Standard

Standard

Standard

Bolted knives

Option

Option

Option

Option

High-cutting skids

Option

Option

Option

Option

Conditioner

V-steel tines

Profiled rollers

-

V-steel tines

Rotor diameter

mm

642 (2'1")

-

-

642 (2'1")

Roller diameter

mm

-

2 x 250 (2 x 10")

-

-

Conditioner speed

rpm

600/900

850

-

600/900

Wide conditioner system

mm

2,050 (6'9")

2,050 (6'9")

-

2,500 (8'2")

Wide spreading guide plates

Option

-

-

Option

Cross conveyor belt

-

-

-

Option

Hydraulic conversion Swath boards

Option

-

-

Option

Tire size / work position

15.0/55-17/10 PR

15.0/55-17/10 PR

10.0/75-15.3/8 PR

15.0/55-17/10 PR

Tires Transport

15.0/55-17/10 PR

15.0/55-17/10 PR

10.0/75-15.3/8 PR

15.0/55-17/10 PR

Area output approx.

ha/h

3.0

- 3.5

3.0

- 3.5

3.5

- 4.0

3.5

- 4.0

(acres/hour)

(7.4

- 8.6)

(7.4

- 8.6)

(8.6

- 9.9)

(8.6

- 9.9)

Input power

kW/hp

51 / 70

51 / 70

50 / 68

59 / 80

PTO speed 1,000 rpm

Standard

Standard

Standard

Standard

PTO speed 540 rpm

Option

Option

Option

Option

Hydraulic couplers

1 x sa

1 x sa

1 x sa

1 x sa

1 x da

1 x da

1 x da

1 x da

Air brake system

-

-

-

-

All specifications, weights and dimensions do not necessarily comply with standard specifications and are therefore not binding.

30

EasyCut 3201 CV

EasyCut 3200 CRi

EasyCut 3210 CV

EasyCut 3210 CRi

EasyCut 3600 CV

EasyCut 4013 CV

EasyCut 6210 CV

side-mount

side-mount

mid-mount

mid-mount

side-mount

mid-mount

mid-mount

3,140 (10'4")

3,140 (10'4")

3,140 (10'4")

3,140 (10'4")

3,550 (11'8")

4,000 (13'2")

6,200 (20'4")

3,000 (9'10")

3,000 (9'10")

3,000 (9'10")

3,000 (9'10")

3,410 (11'2")

3,860 (12'8")

2,990 (9'9.7")

5

5

5

5

6

5

10

2

2

2

2

2

4

4

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Option

Option

Option

Option

Option

Option

Option

Option

Option

Option

Option

Option

Option

Option

V-steel tines

Profiled rollers

V-steel tines

Profiled rollers

V-steel tines

V-steel tines

V-steel tines

642 (2'1")

-

642 (2'1")

-

642 (2'1")

642 (2'1")

642 (2'1")

–

2 x 250 (2 x 10")

-

2 x 250 (2 x 10")

-

-

-

600/900

850

600/900

850

600/900

600/900

600/900

2,500 (8'2")

2,500 (8'2")

2,500 (8'2")

2,500 (8'2")

2,900 (9'6")

2,500 (8'2")

2 x 2,500 (2 x 8'2")

Option

-

Option

-

Option

-

Option

Option

Option

Option

-

Option

-

-

Option

-

Option

-

-

-

-

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

500/45-22.5

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

15.0/55-17/10 PR

3.5

- 4.0

3.5

- 4.0

3.5

- 4.0

3.5

- 4.0

4 - 4.5

4.5 - 5

7.0

- 8.0

(8.6

- 9.9)

(8.6

- 9.9)

(8.6

- 9.9)

(8.6

- 9.9)

(9.9

- 11.1)

(11.1

- 12.4)

(17.3

- 19.8)

59 / 80

59 / 80

59 / 80

59 / 80

66 / 90

74 / 100

112 / 150

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Option

Option

Option

Option

Option

-

-

1 x sa

1 x sa

1 x sa

1 x sa

1 x sa

1 x sa

3 x da

1 x da

1 x da

1 x da

1 x da

1 x da

1 x da

–

-

-

-

-

-

Standard

EasyCut 3600 CV and 4013 CV: Transport width exceeds 3 m (9'10")

31

Internet

Discover the world at KRONE and browse through our website pages

to find facts and figures and also new developments plus a wide range

of services. Explore our website and find out how versatile the KRONE

world is.

News

Service

Click here to find up-to-the minute information about KRONE -

Here you find all the service information you require - from

from new product presentations to show reviews. Here you are

a point of contact at the factory to finance schemes for your

at the pulse of KRONE life.

KRONE machine as well as training schemes for staff and users.

Products

Find extensive information on our full product range. This section

Download Center

holds everything you need - from video clips to manuals.

Are you looking for a KRONE calendar for your desktop or a

smart picture for your presentation? Here, at the KRONE

download center, you will find plenty of useful material for a wide

Sales organisation

range of projects.

Here you find a distributor in Japan as well as your local KRONE

dealer who will be pleased to support you. This is where you find

Used Machinery

your KRONE partner who will be pleased to assist you.

KRONE often has a wide range of demonstration or exhibit

machinery on offer. This is a good site to find your KRONE

Jobs

machine. Then contact your local KRONE dealer to arrange the

Would you like to join our company? KRONE is often looking

details of a potential purchase.

for diligent and motivated staff to work at our farm machinery

factory as well as at our commercial trailer production plant. So,

Parts

this section is always worth a visit.

24 / 7... This service gives you the opportunity to find your

KRONE part at any time and without waiting. The KRONE

Media center

Agroparts Portal has an article number and exact description for

The KRONE ‘database’ holds thousands of documents, pictures,

every part. You can order the part instantly at your local KRONE

test reports and much more. Here you find very detailed

dealer by sending an e-mail to Agroparts.

information on KRONE products that are of special interest to

you.

KRONE shop

Are you looking for a gift or are you a collector of farm models?

Events

Then you should definitely shop around at our KRONE shop. We

Are you in for a KRONE live experience? Check out for KRONE

take your orders at any time of the day.

events and look at a machine on show or watch it during a

demonstration. After all, there is little that is more effective than

a hands-on experience.

Your KRONE dealer

Maschinenfabrik Bernard KRONE GmbH

Heinrich-Krone-Straße 10

D-48480 Spelle

Telefon: +49 (0) 5977. 935-0

Telefax: +49 (0) 5977. 935-339

info.ldm@krone.de