AM

High-comfort and high-efficiency

mowers

Side-pull mowers with huge pivoting angle

Driveshaft powered gears for ultimate efficiency

Massive spur gears for quiet running and longevity

Robust and fully welded cutterbar

Quick-fit blades for quick and easy change

(Not available in North America)

Pivoting V-shaped steel tines for optimum conditioning

2

| AM 10/11

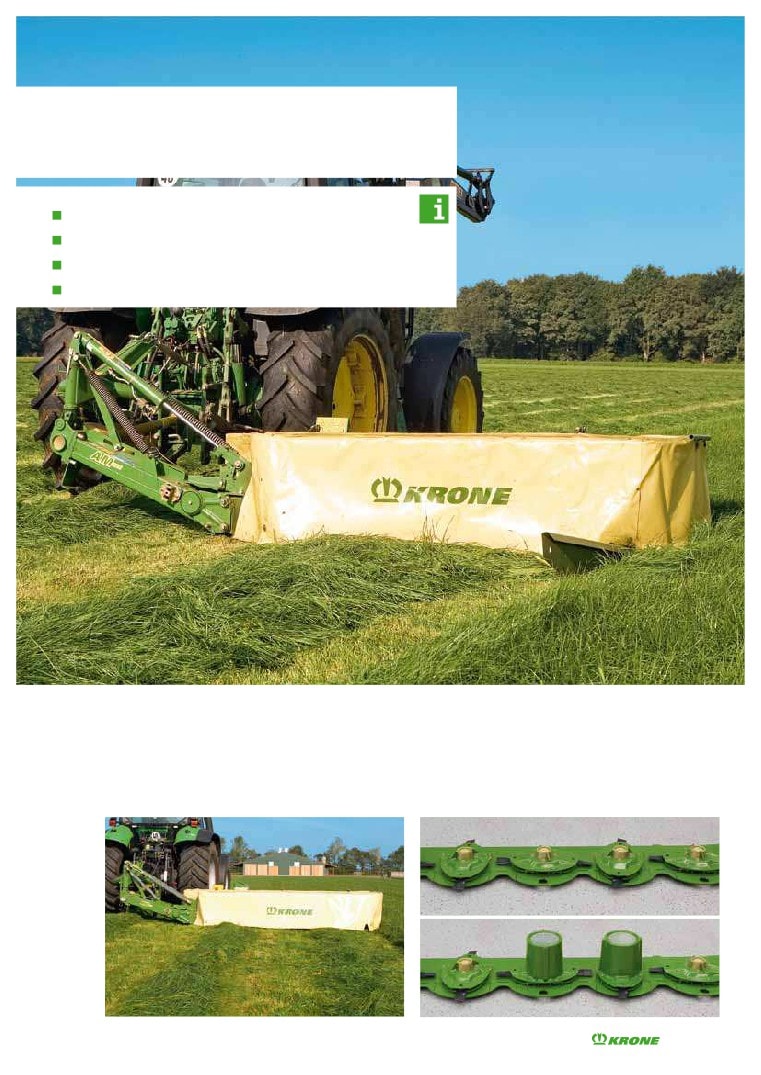

Our AM range of mowers has

evolved from extensive farmer ex-

perience around the world. Proven

so well, these machines are desi-

gned to perform in heavy-duty ap-

plications while being easy to use.

EasyCut cutterbar

4

Attachment, driveline,

locking system

6

AM S

8

AM CV

10

Spreading the material

12

Technical data

15

3

AM 10/11 |

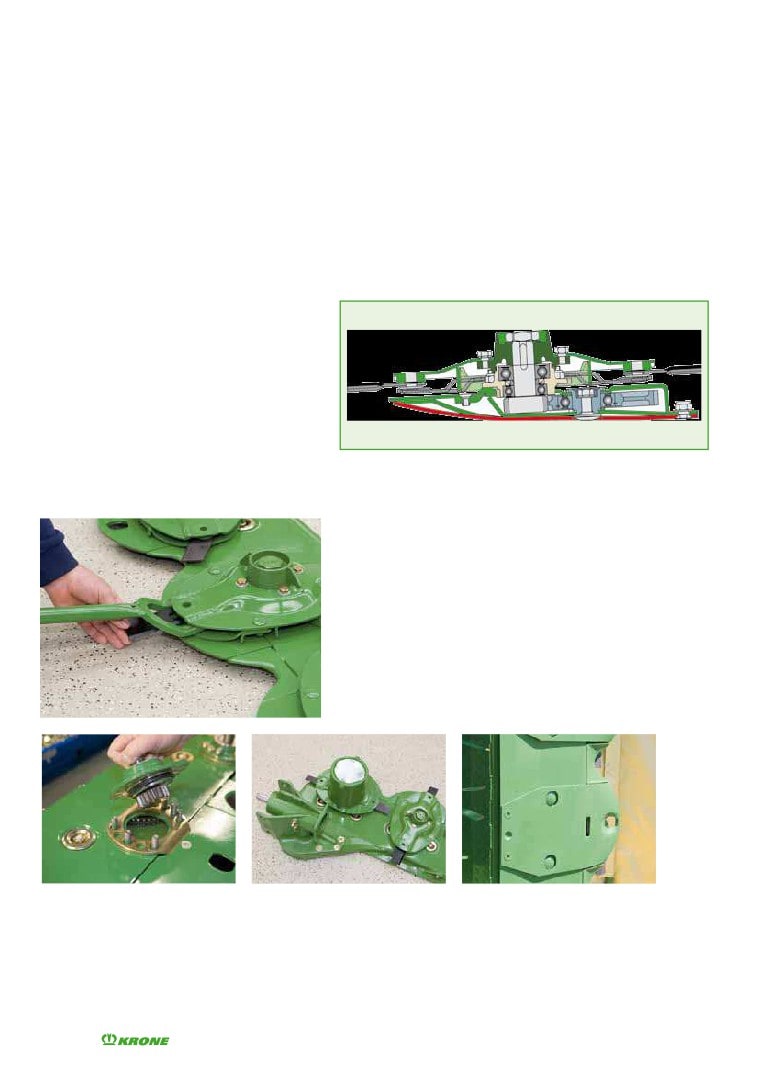

EasyCut cutterbar

Your cutting edge

Robust and fully welded cutterbar

Long-lasting spur gears

Wedge-shaped cutterbar without inner shoe for cleanest cuts

Convenient and quick-change blades (Not available in North America)

Smooth and heavy-duty driveline:

Satellite driveline:

Massive and heavy-duty spur gears with up to 59 teeth take the pto

This powerful concept uses one main

power and transfer it to the discs without losses, ensuring each disc is

gearbox and combines it with a number

driven full power. Each of the auxiliary gears uses smaller spur gears to

of auxiliary gearboxes, which mount in

drive one disc at a time, a design that minimizes the load on each gear

a forward position for optimum blade

and results in quiet running and longevity.

overlap and perfect cuts.

4

| Vario| AM 10/11

EasyCut - the ultimate cutterbar

Perfect and clean cuts are pivotal for high-quality forage. KRONE

mowers deliver perfect results. These high-quality machines are

strong, sturdy and absolutely dependable.

Better cuts:

The wedge-shaped and fully welded cutterbar provides perfect cuts

even in the most difficult conditions. For complete peace of mind, the

discs operate fully protected by the cutterbar, spinning on massive

double bearings to absorb peak loads in permanent operation.

Quick-change blades:

Quick-change DS blades (DS = double

safety) provide for easy and fast knife

change or replacement on the site.

(Not available in North America)

Straightforward:

No inner shoe:

Gentle on the turf:

The spur gears that drive the discs

The gearbox is arranged behind the

The extremely wide skids are

are removed from above; the spur

inner top hat, a layout that makes

fabricated from hardened boron

gears in the main gearbox are

for clean cuts on the headland and

steel to minimize the ground

removed from the side.

in awkward plots without the mower

pressure and give enhanced contour

pushing up the cut material.

following and cutterbar protection.

5

AM 10/11 |

AM

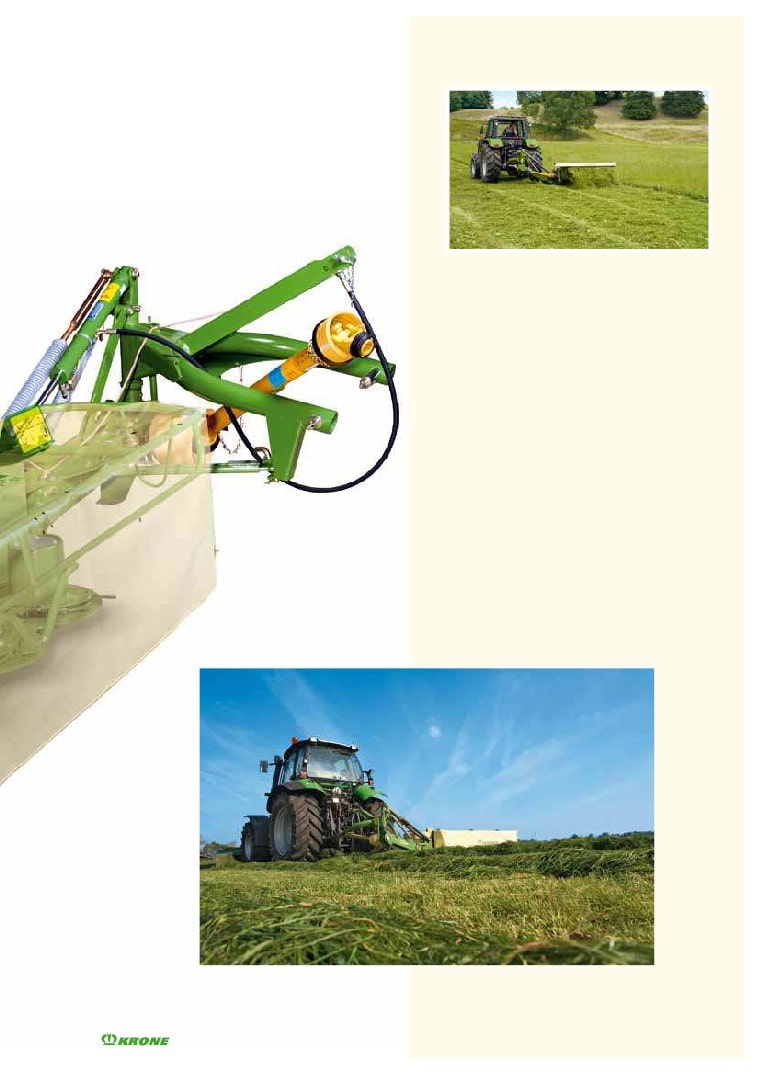

AM - the working formula

Tractor link fitting pins for full-width efficiency

Direct and frictional driveline ensures no power is lost

Suspension springs adjust to optimize ground pressure

Large pivoting angle suits work on steep side slopes

Heavy-duty stability:

Full work width:

The sturdy three-point headstock features a bracket to

The operator can refit link arm pins to sideshift the

store the driveshaft after the machine is removed from

machine and ensure it is cutting at its full width behind

the tractor.

various tractors and different wheelbases on side slopes

and in combination with a front mower.

6

| Vario| AM 10/11

Perfect in all conditions

KRONE disc mowers evolved from a sustained cooperation among farmers,

scientists and developers. The linkage system is compact, low in weight and

swings the mower through a large angle up and down, providing AM excel-

lent ground contour following and adaptation to hilly terrain.

Constant-velocity and high-power driveline:

Drive power flows through a frictional drive-

line of pto shafts and gears, a system that

warrants an efficient transfer of power from

the tractor down to the cutterbar discs - even

in difficult conditions.

Absolutely safe:

Varying the ground pressure:

The KRONE break-back system relies on

The coil springs adjust to optimize the ground pressure and

an adjustable coil spring, which responds

machine adaptation to current conditions. Reducing the ground

instantly and dependably and allows the

pressure reduces the machine’s power input.

mower to swing back and up when impacting

a foreign object.

7

AM 10/11 |

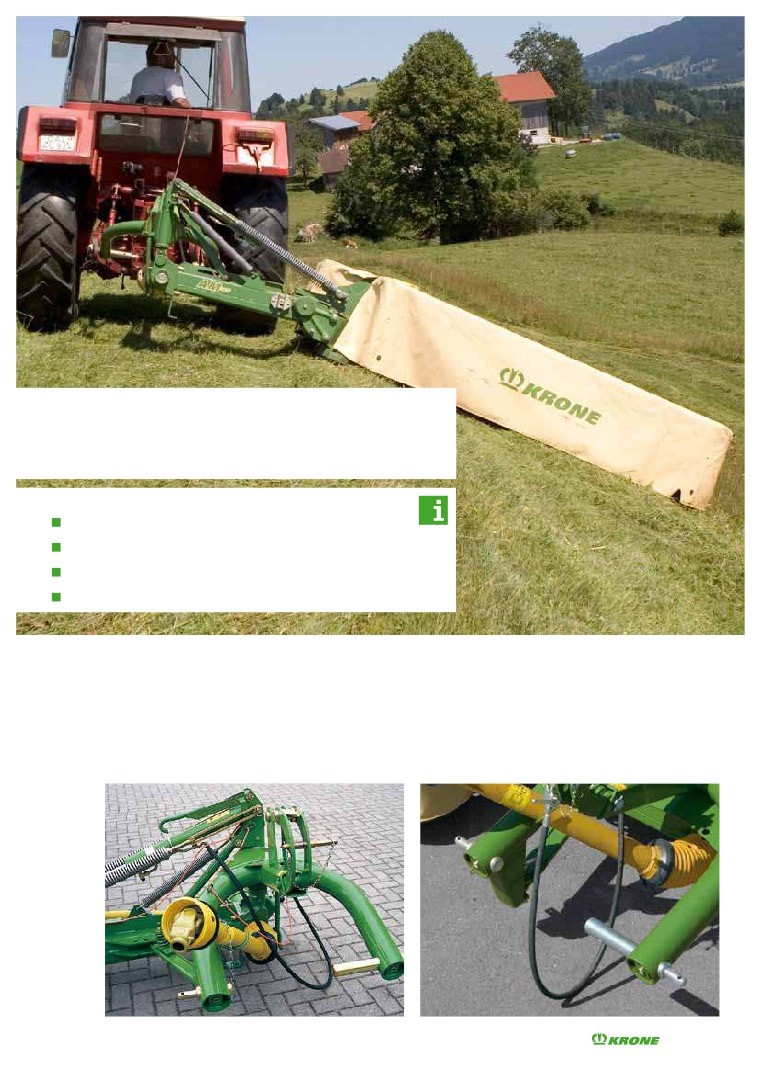

AM

Technology that delivers

High workrates

Low input

Light weight

Excellent value for money

Two swaths:

Spreading:

The AM 323 S model features central top hats that

In order to spread the crop across the machine width,

windrow the cut material into two swaths to keep cut

replace the central top hats on AM 323 S by discs. The

material clear of the tractor wheels on the next pass.

discs must be spinning in pairs.

(Standard in North America)

8

| Vario| AM 10/11

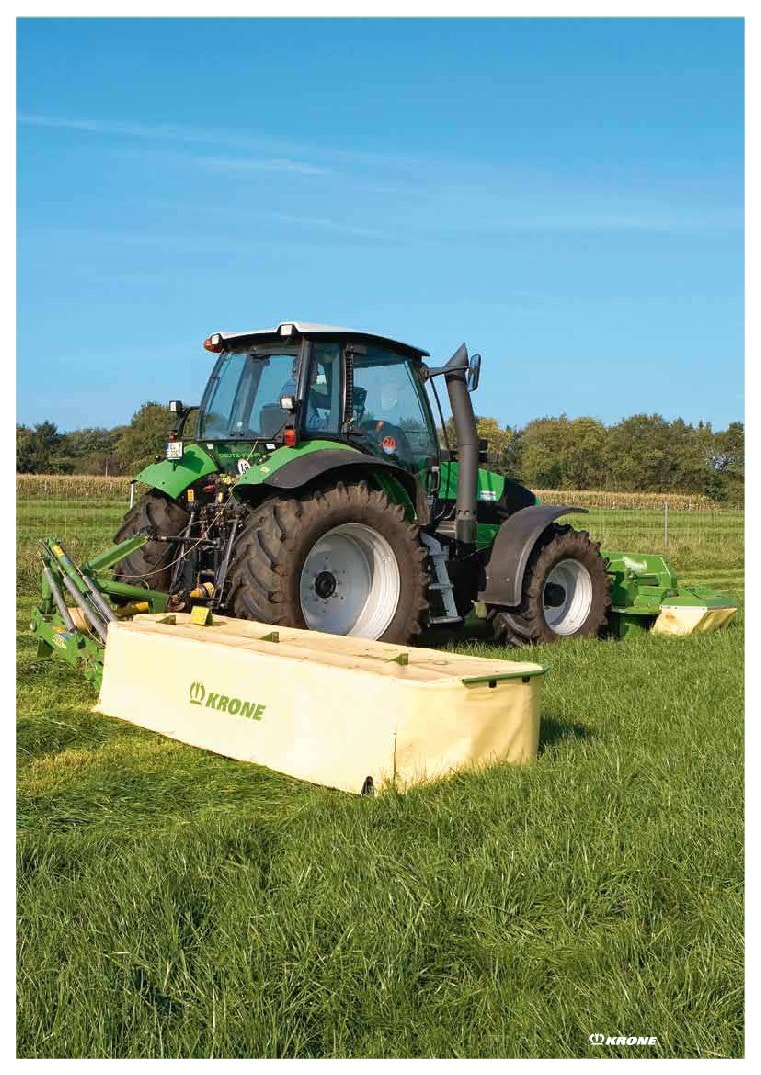

The dependable system

Peace of mind comes from using

innovative and top-quality machinery

thatimpressesbyanexemplaryoutput–

machinery like the KRONE range of

AM disc mowers with working widths

from 2.0 to 3.2 m (6'7"-10'6"), which has

provenwellaroundtheworld,feature

superiorstabilityanddeliverexcellent

results.

Linear crop flow:

All KRONE disc mowers without conditioner feature a

cantilevered guard that makes for an unobstructed flow

of the material through the machine, delivering uniform

swaths that speak for themselves.

Operator comfort on the headland:

Perfect handling on the road:

On the headland, the mower is raised hydraulically

Only one single-acting hydraulic coupler is required to

to enable convenient turns and avoid running on cut

swing our AM model with/without conditioner from its

material. The link arms are not raised. A stop limits the

working position into the headland or transport position.

lift range.

In transport position, the mower is extremely compact

for easy, safe and swift road transport.

9

AM 10/11 |

The CV tine conditioner

with V-shaped steel tines

Top-quality forage across the full working width

Uniform conditioning across the full work width

Intensive conditioning from pivoting V-shaped steel tines

and an adjustable baffle plate

Optimum conditioning from a mechanical rotor drive

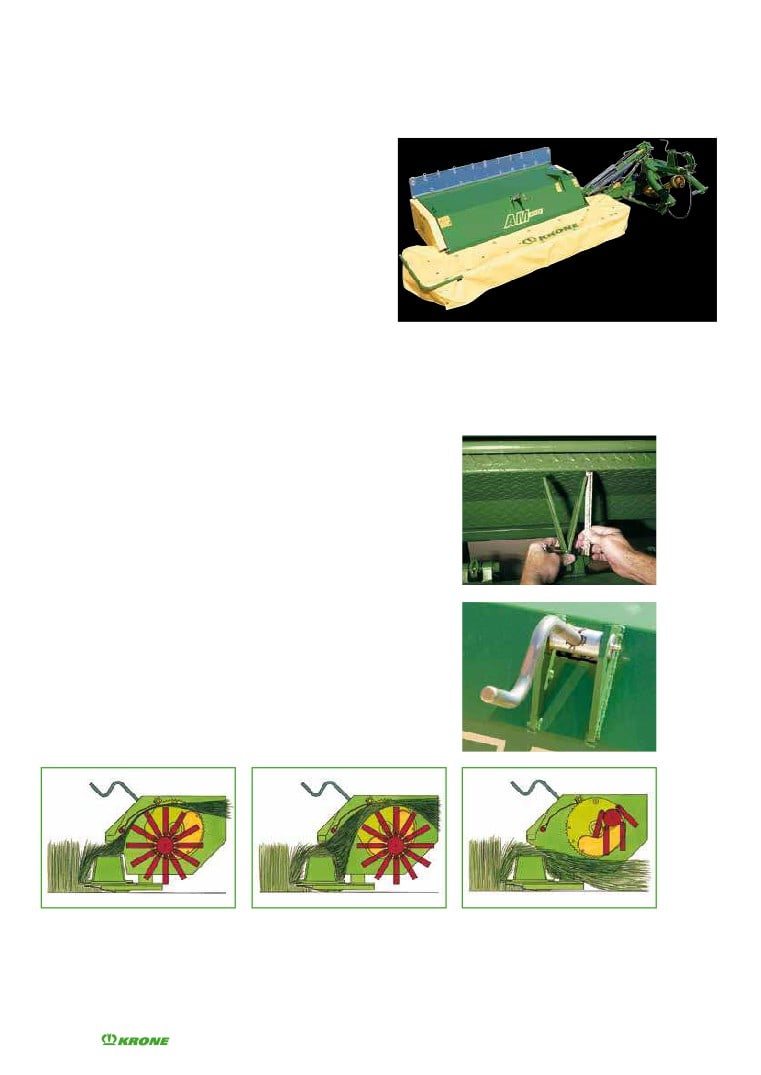

0 rpm, 600 rpm or 900 rpm:

AM 243 CV with pivoting conditioner:

The integral three-speed mechanical gearbox offers

Semi-toothed adjuster discs on either machine end

highest operator comfort. Setting the desired speed

swing the rotor up and to the rear.

range is quick and easy.

10

| Vario| AM 10/11

Success delivered - V-shaped steel tines

Efficiency is one parameter in hay and forage

harvesting, quality is another. The AM 243 CV

model features a mechanical conditioner with

V-shapedsteeltinesandmechanicalgearbox,

which provide optimum crop conditioning,

fastanduniformwiltingandtop-qualityforage.

Freely pivoting steel tines treat every single stem and achieve an

outstanding quality of crop.

It’s intensive:

Pivoting V-shaped steel tines

combine with an infinitely adjustable

baffle plate to provide intensive

conditioning, reduce machine wear

and optimize adaptation to crop

conditions.

It’s stepless:

This crank varies the clearance

between tines and baffle plate to

adjust the conditioning effect. The

narrower the clearance, the more

intensive the conditioning.

It’s perfect:

It’s simple:

The operator sets the clearance

degree of lignification and achieving

When using the machine for cutting

between rotor and cutterbar as he

a perfect cut and exemplary

daily rations or legumes, the opera-

pivots the conditioner, adjusting

conditioning.

tor swings the rotor conveniently to

the system to current yields and

the rear and out of work to use the

machine as a plain mower.

11

AM 10/11 |

Spreading the material

Put in less - finish earlier

Increased wilt and less exposure to weather

Fewer passes and reduced conditioning costs

Optimum treatment for optimum quality

Full-width conditioning:

Specified with V-shaped steel tines, baffle

plate, aluminium hood and optional deflector

plates, the conditioner spans across the

machine’s full work width. The design

provides for a consistent flow of crop and

uniform spreading.

12

| Vario| AM 10/11

Spread as wide as possible

and as narrow as necessary

Scientific research has shown that spreading has a significant

effect on fermentation and quality of the forage. Accordingly,

the hood not only spreads the

material across a large

area but also produces

light and fluffy

swaths, saving

you at least one tedding

pass in many conditions for

improved forage quality, milk performance

and reduced reliance on concentrates.

As you like it:

Compact on the road:

The optional deflectors with pin/hole setting system

KRONE disc mowers offer easy road transport - even

adjust to any angle. Choose between narrow swathing

when equipped with conditioner. The compact design

in wet and boggy terrain or spreading when rapid drying

of AM 243 CV with close attachment to the rear axle

is the priority.

and a low-weight aluminium hood ensure the machine

is easy and safe in road transport.

13

AM 10/11 |

14

| AM 10/11

Technical Data

AM / AM CV

AM 203 S

AM 243 S

AM 243 CV

AM 283 S

AM 323 S

Work width

Approx. mm

2.000 (6'7")

2.400 (7'11")

2.400 (7'11")

2.800 (9'2")

3.200 (10'6")

Three-point hitch

+

+

+

+

+

No. of discs

3

4

4

5

4

No. of drums

2

2

2

2

4

CV conditioner

-

-

+

-

-

Conditioner speed

-

-

0/600/900

-

-

Weight

Approx. kg (lbs)

440 (970)

520 (1.146)

740 (1.631)

605 (1.333)

682 (1.503)

Area output

Approx. ha/h

2

2 - 2,5

2

2,5 - 3

3

Power requirement

kW/hp

27/ 37

30 /41

44 / 60

40 / 55

50 / 68

PTO speed standard

rpm

540

540

540

540

540

Cat

I / II

I / II

II

I / II

I / II

Hydraulic couplers

1 sa

1 sa

1 sa

1 sa

1 sa

All specifications, weights and dimensions do not necessarily comply with standard specifications and are therefore not binding.

Optional high-cutting skids:

Optional swath deflectors on either side:

These adjustable high-cutting skids offer cutting heights

These deflectors are fitted to create narrower swaths.

of up to 14 cm. High cuts are often preferred in fields of

They avoid tractor wheels running on the cut material

less intensive farming.

and are ideal in boggy terrain.

15

AM 10/11 |

Internet

Discover the world at KRONE and browse through our website pages

to find facts and figures and also new developments plus a wide range

of services. Explore our website and find out how versatile the KRONE

world is.

News

Service

Clickheretofindup-to-theminuteinformationaboutKRONE–

Hereyoufindall theserviceinformationyou require–from

fromnewproductpresentationstoshowreviews.Hereyouare

apointofcontactat thefactory tofinanceschemesforyour

at the pulse of KRONE life.

KRONEmachineaswellastrainingschemesforstaffandusers.

Products

Findextensiveinformationonourfullproductrange.Thissection

Download Center

holds everything you need - from video clips tomanuals.

Areyoulooking foraKRONEcalendar foryourdesktopora

smart picture for your presentation? Here, at the KRONE

downloadcenter,youwillfindplentyofusefulmaterialforawide

Sales organisation

range of projects.

HereyoufindadistributorinJapanaswellasyourlocalKRONE

dealerwhowillbepleasedtosupportyou.Thisiswhereyoufind

Used Machinery

your KRONE partner who will be pleased to assist you.

KRONEoftenhasawide rangeofdemonstrationorexhibit

machinery on offer. This is a good site to find your KRONE

Jobs

machine.ThencontactyourlocalKRONEdealertoarrangethe

Wouldyouliketojoinourcompany?KRONEisoftenlooking

details of a potential purchase.

fordiligentandmotivatedstafftoworkatourfarmmachinery

factoryaswellasatourcommercialtrailerproductionplant.So,

Parts

this section is always worth a visit.

24 / 7...This service gives you the opportunity to find your

KRONE part at any time and without waiting. The KRONE

Media center

AgropartsPortalhasanarticlenumberandexactdescriptionfor

TheKRONEdatabase’holdsthousandsofdocuments,pictures,

everypart.YoucanorderthepartinstantlyatyourlocalKRONE

test reports and much more. Here you find very detailed

dealer by sending an e-mail to Agroparts.

informationonKRONEproductsthatareofspecialinterestto

you.

KRONE shop

Areyoulookingforagiftorareyouacollectoroffarmmodels?

Events

ThenyoushoulddefinitelyshoparoundatourKRONEshop.We

AreyouinforaKRONEliveexperience?CheckoutforKRONE

take your orders at any time of the day.

events and look at amachine on show orwatch it during a

demonstration.Afterall,thereislittlethatismoreeffectivethan

a hands-on experience.

Your KRONE dealer

Maschinenfabrik Bernard KRONE GmbH

Heinrich-Krone-Straße 10

D-48480 Spelle

Telefon: +49 (0) 5977. 935-0

Telefax: +49 (0) 5977. 935-339

info.ldm@krone.de