KW/KWT

Powerful rotors turning crops

into high-quality forage

Complete range of mounted and trailed models

Maintenance-free driveline with 8-finger OctoLink clutch

Maintenance-free, liquid-grease lubricated gearboxes

Hardwearing Super-C tines

Central border spreading control

Maximum operator comfort

Robust box sections

2

| Rotary tedders 09/13

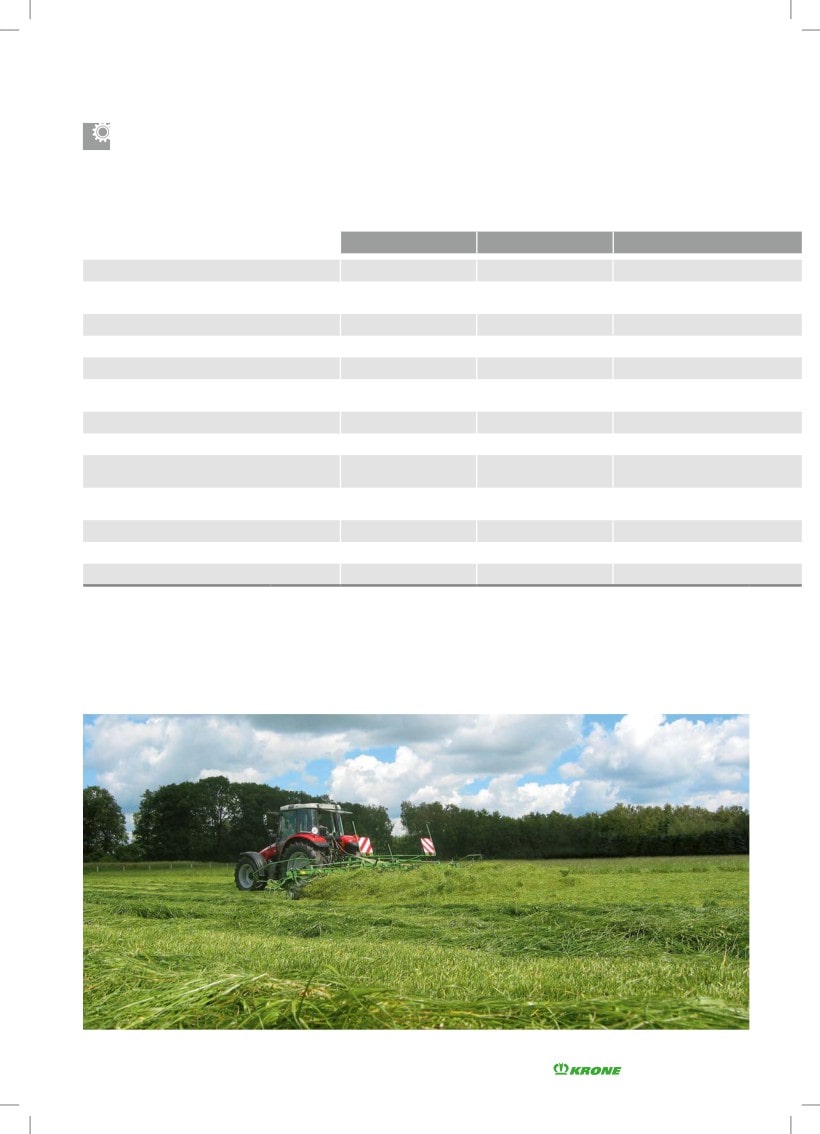

In-field experience by the thousands

KRONE’s extremely robust and easy-

to-use rotary tedders have proven

their worth tens of thousands of times

around the world

Impressive features

4

Mounted rotary tedders

4, 6, 8 and 10 rotors

12

Trailed rotary tedders

without transport running gear

4 and 6 rotors

16

Trailed rotary tedders

with transport running gear

6, 8 and 10 rotors

20

Trailed rotary tedders

without transport running gear

12 and 14 rotors

24

Trailed rotary tedders

with transport running gear

14 and 18 rotors

30

The right tedder to match

your mower

38

Technical Data

41

3

Rotary tedders 09/13 |

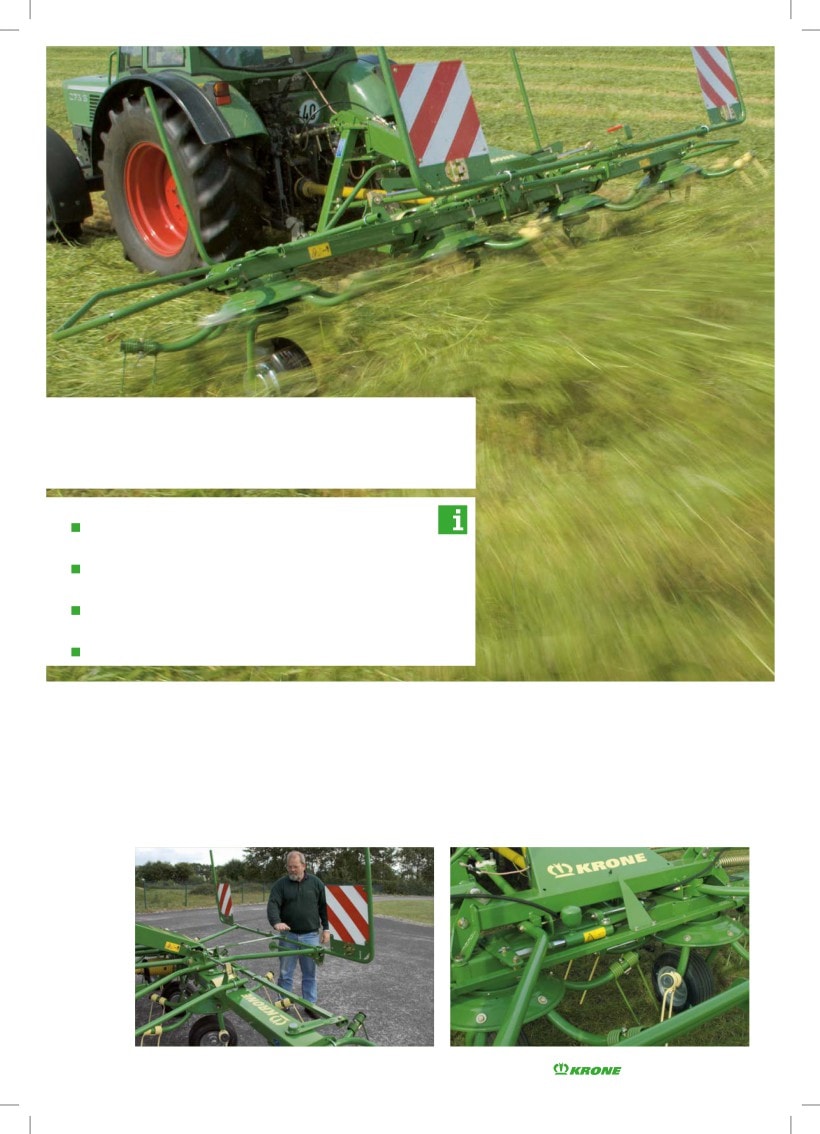

The driveline

Powerful, dependable and maintenance-free

OctoLink

• Maintenance-free 8-finger clutches

• Full drive power in any position

Rotor gearboxes

• Permanently liquid-grease lubricated bevel gears

• No service, no maintenance, long service life

• Absolutely leak-proof

Permanently lubricated rotor gearboxes

Heavy-duty

The enclosed liquid-grease lubricated gearboxes

Mounted beneath the individual sections, the liquid-

that drive the rotors are absolutely maintenance-free.

grease gearboxes drive nothing but the rotors. The

Permanent lubrication gives peace of mind and

same sections guide the rotors on the KW models,

increases the machine’s longevity. The chunky box-

which increases the overall stability and takes the load

section chassis absorbs all shock loads on the frame.

off the gearbox.

4

| Rotary tedders 09/13

The dependable system

When it comes to preparing wilted silage and hay, KRONE is the manufacturer that

offers a large and extensive range of high-quality and dependable rotary tedders.

Ŧhese machines not only deliver high-quality work and feature a high level of standard

specification but also boast a host of innovative features including maintenance-free

OctoLink finger clutches and liquid-grease lubricated

gearboxes to drive the rotors.

OctoLink:

OctoLink is our extremely hardwearing clutch,

which forms a frictional connection at all times

and yet requires no attention at all. Some of its

eight fingers are always in mesh, even when

the rotors are folded through 180 degrees.

Simple but sophisticated

OctoLink makes it compact

The special design of these short fingers and the way

Offering unprecedented flexibility, OctoLink allows the

they align ensures a consistent flow of power down the

rotors on the outer ends to fold in through 180 degrees,

driveshafts. There is not a single moment the power flow

reducing transport height and storage space require-

is cut. This type of driveline translates into maximum

ment on the one hand while increasing road safety on

efficiency and longevity.

the other.

5

Rotary tedders 09/13 |

The rotors

Teaming up for quality

Cleanest sweeps from double tines with legs of different lengths

Uniform spread as tine arms overlap generously

Heavy-duty and hardwearing - 9.5 mm (0.4") Super C double tines

with 5 coils and tube-section tines

5, 6 or 7 tine arms

The KRONE KW and KWT rotary

used on each rotor also vary to suit your

with 5 tine arms per rotor, medium-

ŧedders are available in various work

special needs and requirements. Pick

sized diameter rotors with 6 tine arms

widths and dimensions. Yet the rotor

the KRONE machine that is ŧailored to

and large-diameter rotors with up to 7

diameters and the number of tine arms your conditions - small-diameter rotors arms.

5

6

5

7

5

6

4

4

1

1

1

4

3

3

2

2

2

3

6

| Rotary tedders 09/13

Clean forage, uniform spread

Quality requires us to start with the basics.

This is how we achieve high standards. The

rotors on the KRONE rotary tedders are the

ideal equipment to produce quality forage for

on-farm use. These rotors spin for you - in

hay and silage.

Professional

The two 9.5 mm (0.4") legs that form one pair

of tines vary in length to provide the special

KRONE combing effect for optimum treatment

and cleanest forage. Five coils on each Super

C steel spring tine give flexibility and strength.

Special stops on the ends of the tube-section

tine holders ensure no tines are lost.

Adjusting to needs

The hex-head bolt on a separate eccentric plate

instantly locks the double tine in one of three positions

to provide more or less vigorous action and achieve

optimum results in all conditions.

High performer in arduous conditions

Uniform distribution of the material

Heavy-duty tine arms (38 mm x 4 mm (1.5" x 0.2") tube

The tine arms mesh as they rotate, spreading the

steel) and a special ring attachment system combine

material uniformly across the working width to ensure

to provide dependable performance in tough and per-

the best possible wilt for quality forage.

manent operation. KRONE technology gives you true

peace of mind in the most difficult conditions.

7

Rotary tedders 09/13 |

All inclusive

The meaningful system

Central border spreading control spreads the crop away

from the boundary for easier harvesting

The angle of throw is adjusted without tools to adapt to

varying crops and yields

The rotors run on large wheels with inner tubes, which give excellent

guidance for cleanest sweeps and dependable operation

Anti-wrap guards ensure a smooth crop flow and trouble-free work

One movement

Hydraulic and convenient

The manual border spreading control system is base

A hydraulic border spreading system is base speci-

specification on all three-point hitch machines and on

fication on the KW 11.22/10, KWT 7.82/6x7 to KWT

the trailed KW 5.52/x7 T and KW 7.82/6x7 T models.

11.22/10, KW 13.02/12 T and KW 15.02/14 T models

Adjustment is easy and simple. One lever swings all

whereas it is an option on all other three-point linkage

wheels to the left or right.

machines. The system is operated from the cab.

8

| Rotary tedders 09/13

Fascinating details

Thought-through details and high operator comfort boost the efficiency of your operation.

The central border spreading facility ensures you are not wasting a single stem along the

boundaries. In addition, it allows you to spread uphill with the machine running at an angle

to the tractor. The rotor tilt is adjusted without the need of tools for perfect adaptation to the

current crop and yield. Tedding every stem, the machine provides uniform conditioning for

best quality feed.

Tedding at a steep angle, turning at a shallow angle

Setting the angle from 13 to 19 degrees is an easy job,

which is carried out quickly on a pin-and-hole system

on the brackets that hold the wheel arms. The steep

position is preferred during tedding; the shallow position

is best for turning. Also, the angle setting system adapts

the rotors accurately to the stubble height and yield,

ensuring thorough work across the full work width.

Large wheels

Wrapping - no thanks

Excellent castering

Each rotor runs on a large wheel. The

Anti-wrap guards are base specification

The wheels are controlled by the

16/6.50-8 and 18/8.50-8 balloon tyres

on the KRONE rotary tedders, ensuring

border spreading control linkage, which

with inner tubes give peace of mind,

the wheels and arms stay clean and

ensures positive castering. The system

protect the turf and give excellent

unobstructed.

also provides for optimum performance

castering.

on the slope.

9

Rotary tedders 09/13 |

The headstock

Compact and safe

The machine automatically moves into a central position

as it is raised, offering a convenient transport position

Damper braces with compression springs provide for

excellent tracking

Compact and safe on the road

Strong

Nimble

The headstock rests on a separate stand, which folds

The pivoting headstock provides the maneuverability

down to support the machine. The driveshaft is stored

required to manage the tightest turns, allowing you

in a separate holder on the headstock. The stand locks

to

attend every corner, leaving nothing behind and

in place automatically when not in use.

matching up with the previous pass without time-

consuming headland maneuvers.

10

| Rotary tedders 09/13

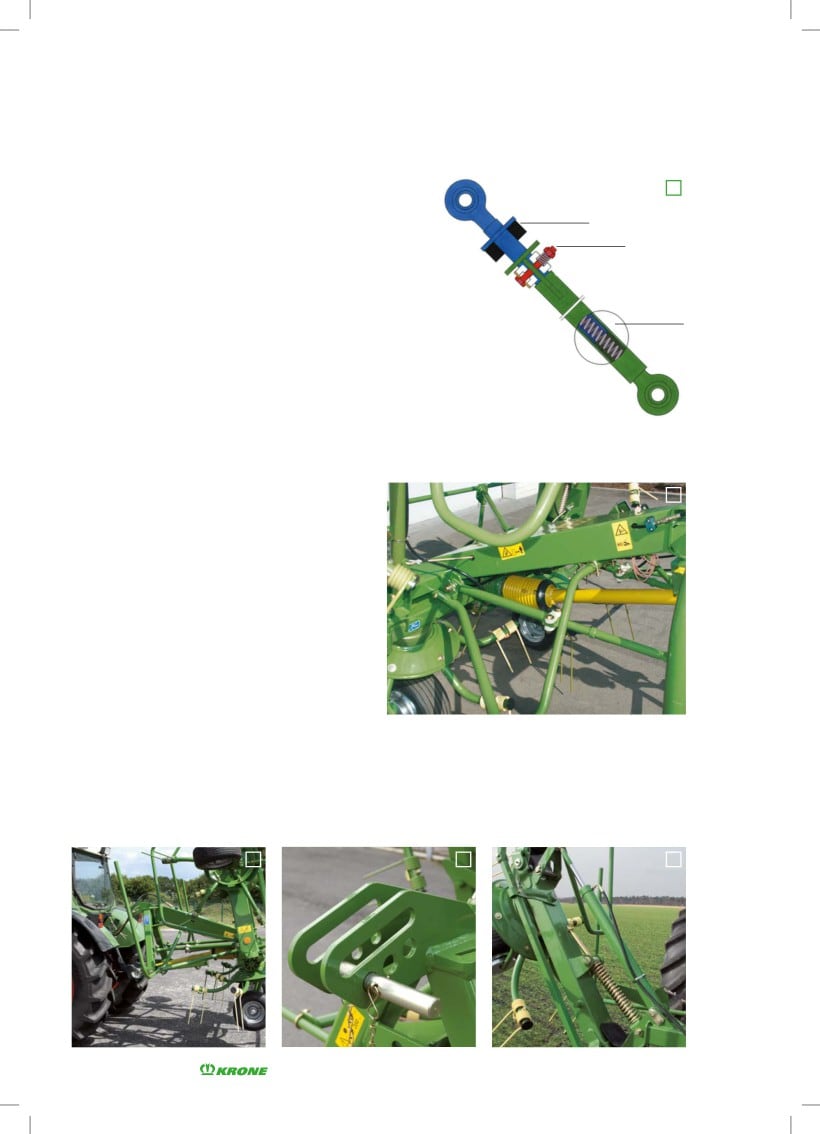

Handling excellence

A KRONE rotary tedder is robust, offering

1

excellent road safety, positive castering and

3

convenient adjustment from the cab. Folded into

2

transport position, the machine offers a low center of

gravity for compact and safe travelling between fields and

1

compact storage.

2

1. + 2. Dampers for an enhanced ride quality

The internal compression spring (1) prevents under

running when working downhill and the adjustable brake

(2) prevents bouncing. The large machines of a 7.80 m

(25'7") plus work width have additional Eladur spring

elements (3), which enhance rides on public roads and

bumpy dirt roads.

3. Automatically locked for transport

As the machine is raised into transport position, the

damper braces maintain the machine in a central

position behind the three-point headstock.

4. Thorough work

5. Hydraulic and convenient

The top link pin fits in one of three holes to provide

One single-acting spool is sufficient to fold the three-point

the best possible depth behind various tractors. An

linkage machines into transport/work position

(except

elongated hole is provided for fitting a leading guide

KW 11.22/10, which require two double-acting couplers).

wheel.

Strong springs back up the hydraulic cylinders to ensure

smooth lowering on the slope.

3

4

5

11

Rotary tedders 09/13 |

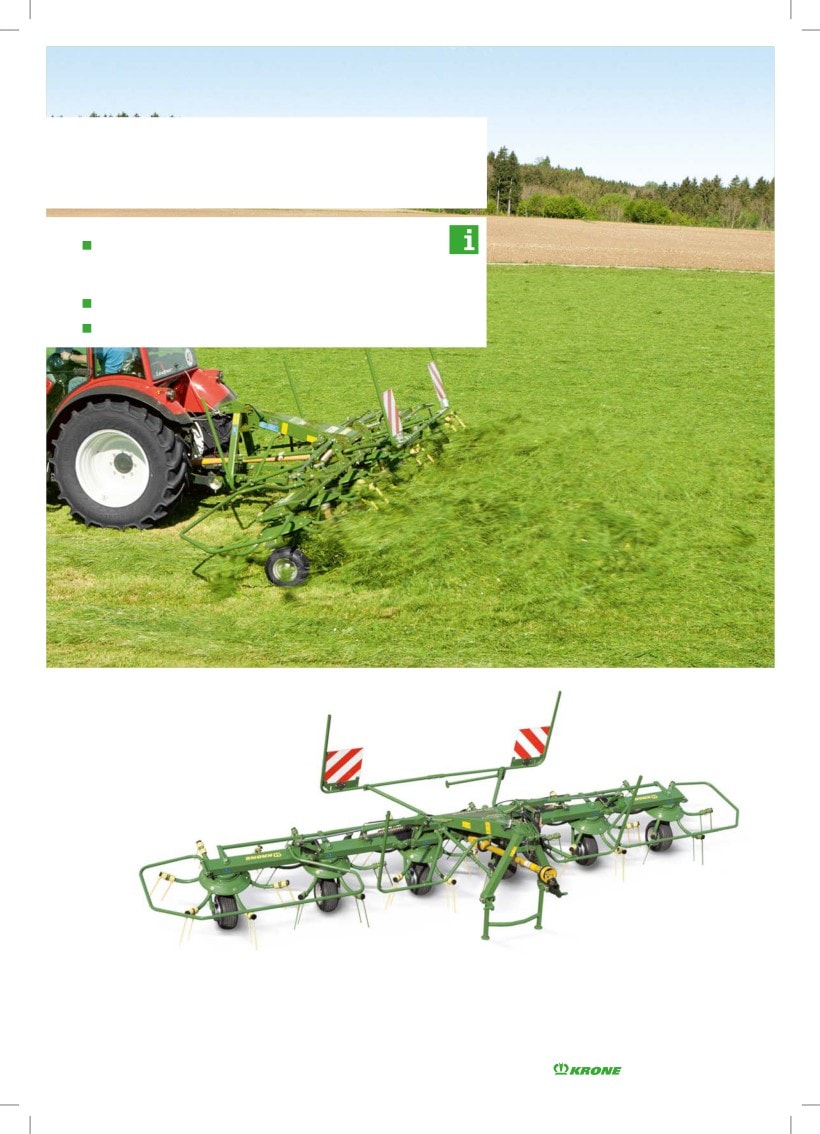

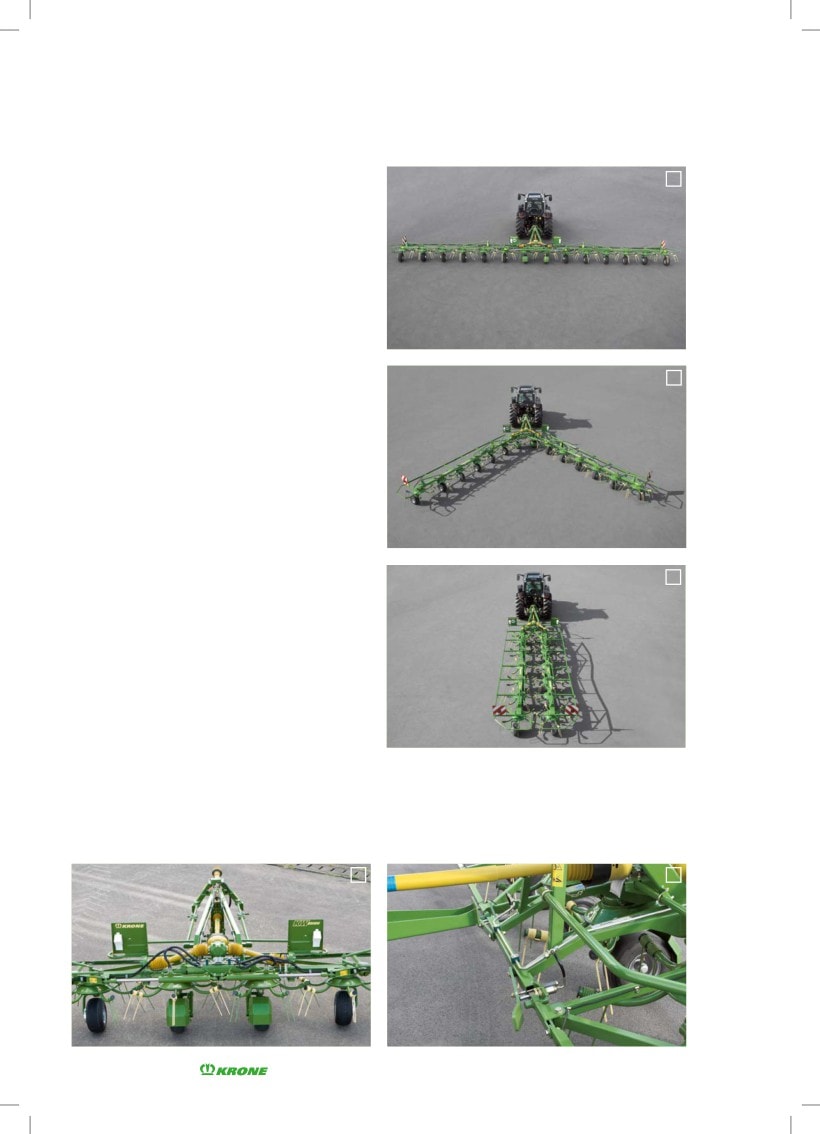

Three-point mounted models

With 4 and 6 rotors

KW 4.62/4, KW 5.52/4x7, KW 6.02/6, KW 6.72/6 and

KW 7.82/6x7 - working at 4.60 m to 7.80 m (15'1" to 25'7") widths

with rotors in various diameters

Central border spreading facility manual or hydraulic control (option)

Convenient operation via a single-acting spool

An ideal system

The rotary tedders KW 6.02/6, 6.72/6, and 7.82/6x7 viding optimum ground adaptation, excellent handling

have six rotors and work at widths of 6.00 m (19'8"), and perfect results, the six-rotor model has become the

6.70 m (22') and 7.80 m (25'7"), which is excellent best-selling tedder in the market place. The small rotors

specification to ted three windrows in one operation

on KW 6.02/6 are excellent in hay.

without the tractor wheels running on the crop. Pro-

12

| Rotary tedders 09/13

Rugged build and easy handling

Featuring strong frames, robust gearboxes and rotors, the

KRONE rotary tedders perform equally well in hay and heavy

crops, having proven themselves best in silage. Pivot joints

on the frame and scores of useful setting options make

KRONE rotary tedders the masters of super clean sweeps

and quality forage.

KW 4.62/4 and 5.52/4x7

Using four rotors and working at widths of

4.60 m (15'1") and

5.50 m (18'1"), these

lightweight machines are tailored to small

businesses and hill farming operations. The

machines feature central border spreading

and rotor tilt adjustment as base specification.

Compact design

The rotary tedders KW 4.62/4 and

KW 5.52/4x7 benefit from a low

deadweight, close attachment to

the tractor and standard warning

panels to ensure swift and safe road

travel.

The border spreading facility

Built-in road stability

Manual border spreading control comes as series

As the wings fold up, the machine’s transport width

specification with hydraulic control as an optional extra.

shrinks to less than 3.00 m (9'10"), making for safe

Requiring only one single-acting tractor spool, these

and compact travel on the road. The mounted 6-rotor

machines change from border spreading to folding from

versions naturally feature an automatic self-centering

a directional control valve.

system, which brings the machine centrally behind the

tractor.

13

Rotary tedders 09/13 |

Three-point mounted models

With 8 and 10 rotors

KW 7.92/8, KW 8.82/8, KW 11.22/10 - working at widths of

7.90 -11.00 m (25'11" - 36'1")

Small diameter rotors are uniformly spaced for a uniform wilt

Damper braces with Eladur spring elements enhance smooth rides

Fold-in end rotors reduce transport height

Quality forage from 8 rotors

The 7.9 m (25'11") KW 7.92/8 and 8.8 m (28'11") that stand out for their heavy-duty and tried and tested

KW 8.82/8 models with 8 rotors and the 11 m (36'1") build. Each of the small-diameter rotors boasts 6 tine

KW 11.22/10 models with 10 rotors are forage specialists

arms that deliver superior tedding.

14

| Rotary tedders 09/13

Work wider and reduce costs

The KW 7.92/8, KW 8.82/8 and KW 11.22/10 models are attached to the tractor’s

ŧhree-point linkage. Dispensing with the transport running gear, these machines are

marketed at a very competitive price and still offer a high level of base specification

features including central border spreading control. The KW 7.92/8 und 8.82/8 models

are controlled via a single acting spool whereas the KW 11.22/10 requires two double

acting spools. With all rotors spaced at

identical distances, the machine produces

uniform spread patterns.

Clean sweeps along boundaries

Nobody can afford to waste their crops and so KW 7.92/8

and KW 8.82/8 offer manual border spreading control as

standard specification and hydraulic control as an option.

KW 11.22/10 is equipped with a standard hydraulic border

Safe travel on the road

spreading system. All wheels are controlled centrally, not

KW 11.22/10 folds into a compact storage ‘package’

only for tedding along boundaries but also for ‘uphill’ work.

(3.75 m (12'4") high). Its 2.98 m (9'9") transport width

makes road travel a safe and relaxed affair.

Quiet road travel

Running on big boots

Wide wings fold to a narrow

The damping braces have extra

Large 18x8.50 balloon tyres carry

ŧransport width

Eladur spring elements to absorb

the central rotors to protect the

The wings are operated hydraulically

the shock loads from road travel

sward and provided good stability

from a single-acting spool. The

and enhance operator comfort.

when KW 8.82/8 or KW 11.22/10

outer rotors swing in to reduce the

folds into transport position.

machine’s transport height.

15

Rotary tedders 09/13 |

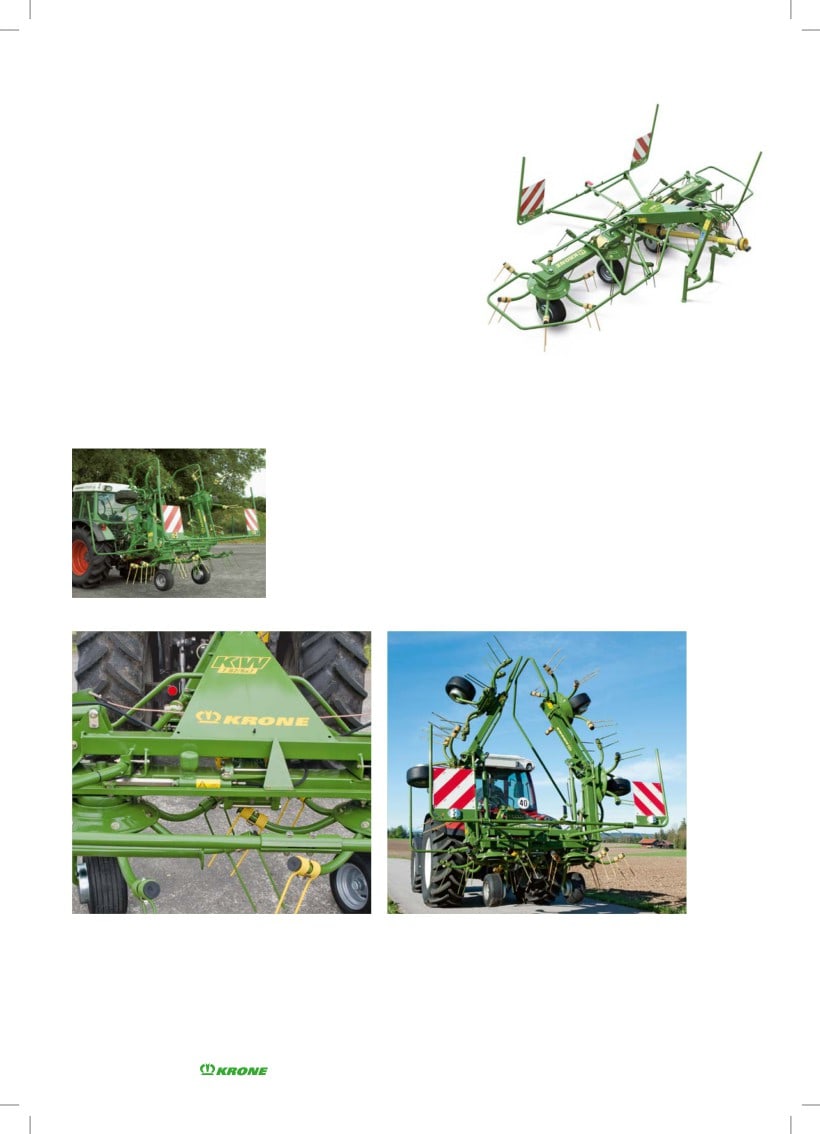

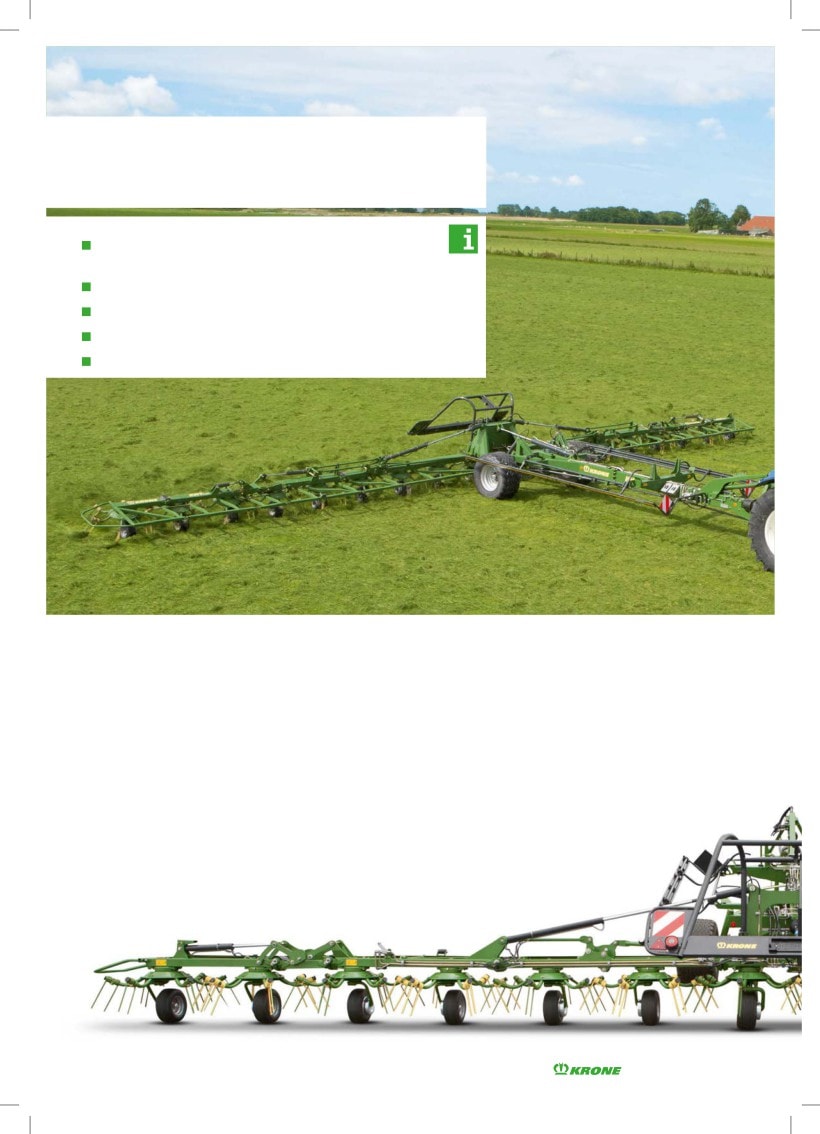

Trailed models

4 and 6 rotors

KW 5.52/4x7 T, KW 7.82/6x7 T

5.50 m-7.80 m (18'1" - 25'7") work widths

Minimum input requirement

No load is taken off the tractor’s front axle

Easy tractor attachment/removal

Hydraulic pivoting drawbar moves conveniently into transport position

The pivoting drawbar

Tractor-based adjustments

The models KW 5.52/4x7 T and KW 7.82/6x7 T feature

The hydraulic drawbar provides for plenty of ground

a height-adjustable pivoting drawbar. Attachment and

clearance under the rotors when the machine is travel-

removal is quick and easy - either via a swinging or rigid

ling to the next site. When using the swinging drawbar

drawbar.

or the rigid linkage drawbar, work depth is set on the

turnbuckle on the hydraulic ram.

16

| Rotary tedders 09/13

Trailed models are lighter

in weight

The trailed rotary tedders working at

widths of 5.50 m (18'1") and 7.80 m (25'7")

stand out for their low ŧractor input requirement.

Running on the middle wheels when in transport, the machine does not mount in the

tractor‘s three-point linkage - which is ideal for smaller ŧractors with lower front axle load

and lift capacities.

Central border spreading facility

The border spreading facility ensures no crop is lost

along the field boundaries. Move this lever to the left or

right to direct the crop to that specific side.

Nice and compact

KW 5.52/4x7 T and KW 7.82/6x7 T are highly compact

models, which require little storage space. Parked on

large balloon tires and a steplessly adjustable stand

on the drawbar, the trailed models offer unsurpassed

stability.

Adjusting the spread angle

Adjusting the angle of spread is important, because it

adapts the machine optimally to the desired quality of

the forage. On KW 5.52/4x7 T and KW 7.82/6x7 T, the

setting is changed by operating an extension lever.

Ŧhere is no need to lift out the machine.

17

Rotary tedders 09/13 |

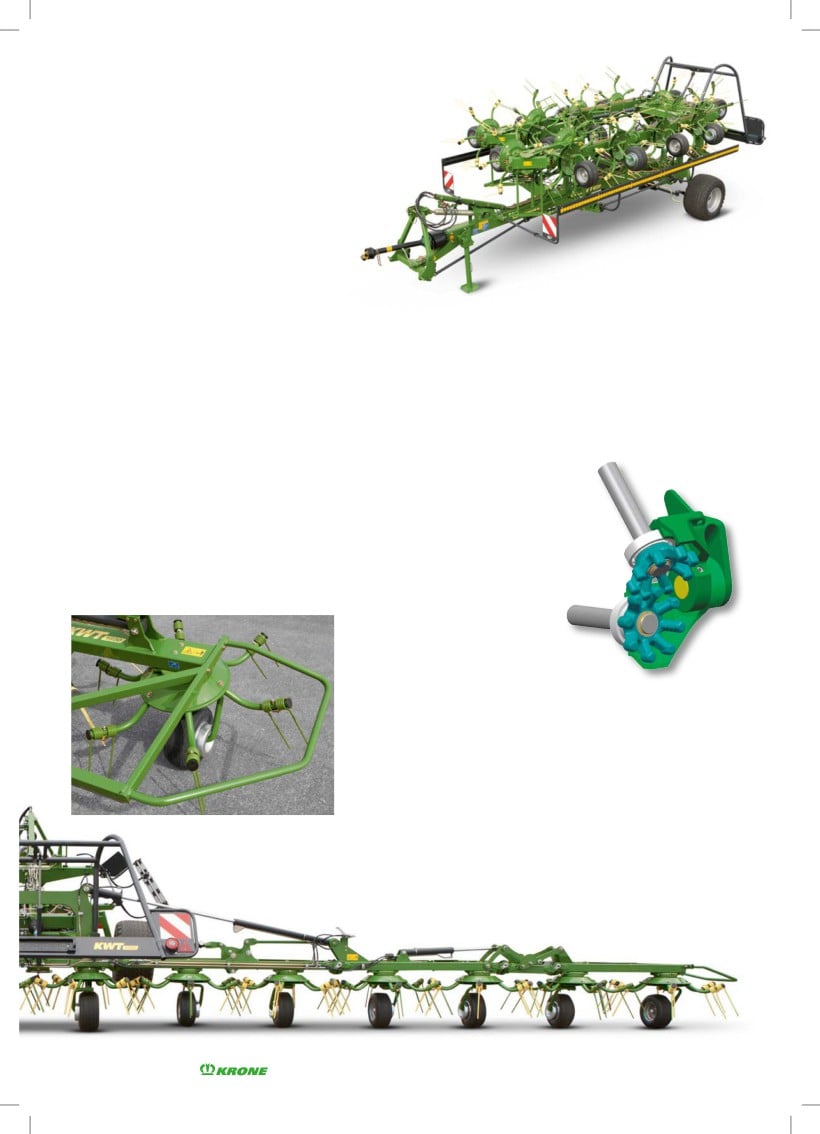

Models with transport

running gear

6 to 10 rotors

KWT 7.82/6x7 / KWT 8.82/8 / KWT 11.22/10

7.80 m -11.00 m (25'7"- 36'1") work widths

Sequence control for maximum operator comfort

40 km/h (25 mph), wide transport running gear, large wheels

Swinging transport running gear, excellent distribution of

weight which does not affect the spread pattern but ensures

effective protection of the sward

Best distribution of loads

Large wheels

On the headland, the running gear swings up and over

Large 10.0/75-15.3 tires on the transport running gear

the rotors, distributing the overall machine weight and

give quiet running and stability in rough and bogie

hence ensuring a perfect and uniform spread across the

ŧerrain as well as when travelling at speed to the next

full work width. There is nothing in the way.

site.

18

| Rotary tedders 09/13

Easy mover

Working at wide widths and behind small tractors,

the models KWT 7.82/6 x 7, KWT 8.82/8 and

KWT 11.22/10 with ŧransport

running gear are the

ideal machines to

operate behind low-

horsepower tractors with

small lift capacities. Working at widths of up to 11.00 m (36'1"), these ŧedders

are yet further evidence that KRONE delivers the goods to modern farming.

Dual power

The running gear on KWT 7.82/6x7 and KWT 8.82/8

lifts and lowers via two single-acting and accumulated

rams. The KWT 11.22/10 model features two double-

acting rams.

Easy ride

The toothed wheels support the hydraulic rams and

increase the transport running gear’s forward swivel

range for enhanced weight distribution during headland

turns.

19

Rotary tedders 09/13 |

1.

2.

3.

4.

5.

Robust, safe and convenient

The headstock suits two-point linkages. The driveshaft

is protected from damage if the link arms lift accidentally.

The foldable stand locks in place automatically.

V-frame

The KWT with transport running gear is pulled by

a

sturdy V-frame. The design and the wide-angle

driveshaft on the pivoting headstock make for tightest

headland turns.

Full adaptation

The pivoting two-point headstock floats over the ground

- a suspension system that cuts out the risk of torsion.

20

| Rotary tedders 09/13

Height-adjustable drawbar

Farmers in some markets prefer a floating drawbar. To

cater for these needs, we market a height-adjustable

hitch for our trailed KWT 8.82/8 rotary tedder.

Easy attachment/removal

The sturdy drawbar is designed like a V to cope with

even the harshest conditions. Attachment and removal

is easy and fast. The stand is steplessly adjusted to the

tractor‘s linkage or the linkage drawbar.

Setting the tedding height

A threaded spindle adjusts the drawbar height, which in

turn controls the working depth.

21

Rotary tedders 09/13 |

Gentle on the sward

Clad with 18x8.50-8 tyres, the wheels running under the

central rotors are wider to carry the transport running

gear in the field, tread gently on the sward and give

quiet running.

Leading wheel

The KWT models are available with optional wheels that

run ahead of the unit. Trailing freely in close vicinity to

the tines and giving stepless height-adjustment, these

wheels ensure absolutely clean sweeps.

No crop is lost

The hydraulic border spreading system throws the crop

to either side and is standard specification on the KWT

machines. This system guarantees that every single

haulm is harvested.

22

| Rotary tedders 09/13

Easy operation

The reversing valve on the models KWT 7.82/6x7 and

KWT 8.82/8 activates the hydraulic border spreading

system, swinging the transport running gear up and

down and the rotors in and out.

No need to leave the cab

KWT 11.22/10 is operated via two double-acting spools

on the tractor. An electric reversing valve is an option,

which allows the machine to be operated from only one

single-acting hydraulic spool.

Sequence control

Conversion from transport to work position and vice

versa is very convenient thanks to sequence control,

which orchestrates the folding sections and the pivoting

running gear.

23

Rotary tedders 09/13 |

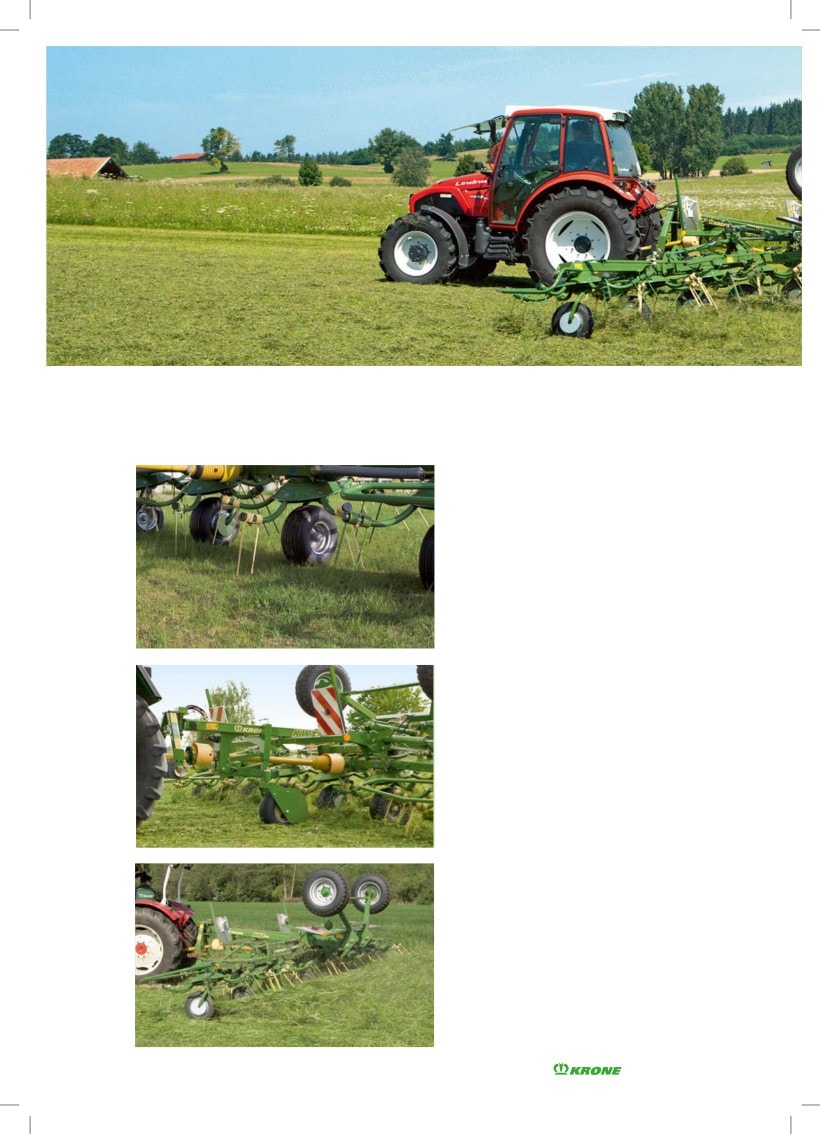

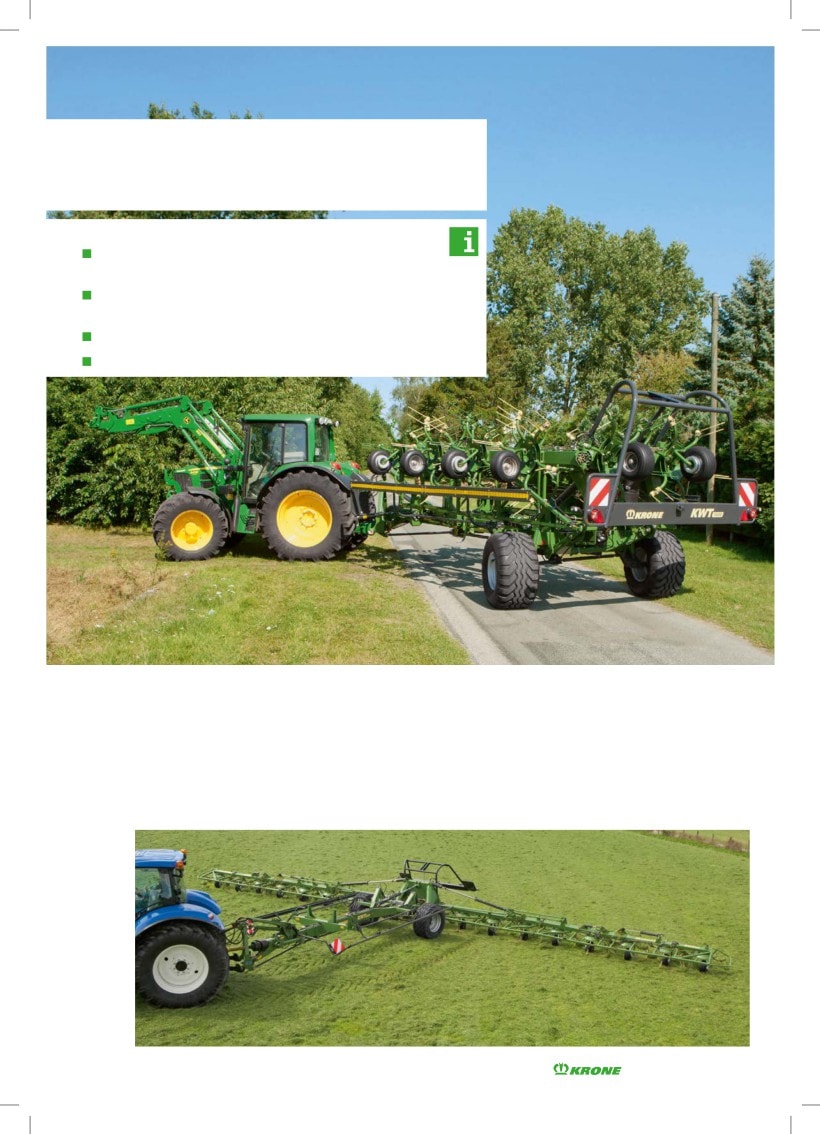

Trailed models

12 to 14 rotors

KW 13.02/12T / KW 15.02/14T

Wide 13.10 m-15.25 m (43'-50') working widths

Uniform spread, small diameter rotors

Quiet castering with damper braces

Maintenance-free OctoLink finger clutches

Maintenance-free, liquid-grease lubricated gearboxes

High workrates

Working at a width of up to 15.25 m (50') and

ŧedding up to 15 ha (37 acres) per hour with only one

single ŧractor are indeed impressive stats. The trailed rotary

tedders from KRONE are hard workers with small rotors that

deliver high-quality work. Operation is easy and convenient, and

stability is also superb. Many thought-through details were implemented in

this machine to achieve the best possible stability. For example, the locking system

that locks the leading guard in place also secures the joints between the individual

sections.

24

| Rotary tedders 09/13

Higher efficiency from wider widths

If you are looking to boost your efficiency and tedding operation, you cannot ignore the large and

trailed rotary tedders from KRONE with work widths of 13.10 to 15.25 metres (43' to 50'). These

rotary tedders are packed with cutting-edge technology and offer an extremely rugged design

and outstanding longevity.

The two-point headstock

The two-point headstock (cat I/II)

is extremely robust. The foldable

stand locks in place automatically.

The headstock also offers a holder

to store the driveshaft.

Setting the work depth from the tractor

Absolutely maneuverable

The work depth is altered by raising/lowering the tractor’s

Irrespective of the position of the headstock, the machine is

link arms. The design gives the driveshaft plenty of ground

able to follow all ground contours. The pivoting suspension

clearance so it will not get damaged if the headstock is lifted

with front ball sockets and idler wheel in the elongated hole

out accidentally.

ensure best adaptation.

Maneuverable V-frame

Superior and quiet caster

KW 13.02/12 T and KW 15.02/14 T are pulled by a sturdy

The damping braces use internal compression springs and

V-frame. The frame and the pivoting two-point attachment

adjustable brakes to ensure the machines (which can be up

make for tightest headland turns.

to 15.25 m (50') wide) caster without swerving.

25

Rotary tedders 09/13 |

A machine customized

to your needs

Fold/unfold while stationary

Easy operation

Compact transport position

Built-in road stability

40 km/h (25 mph) road travel

Shifting weight for quiet running

As some wheels are raised during transport, extra in transport. The two leading wheels and the two wheels

weight is shifted to the four central wheels, the two at the rear caster freely. This innovative configuration

leading wheels and the two trailing wheels. The four leads to quiet running at high speeds and provides for

central wheels are rigid, acting like a tandem axle when

great maneuverability and very easy steering.

26

| Rotary tedders 09/13

Straightforward

Conversion from transport to work and vice

1

versa: The tractor stops and the operator

carries out all operations from the cab.

2

1. - 3. From wide to narrow

Double acting rams fold up the two

wings, then the wheels swivel hydrau-

lically through 90 degrees. That’s all.

Just accelerate the tractor and travel to

the next field - at 40 km/h (25 mph) and

a transport width of as little as 2.88 m

(9'5").

3

In synch

Built-in stability

The two wings of the tedder are driven by a central

The guard frames interlock automatically when in work

gearbox and are operated by double-acting rams to fold

position to take the load off the folding rams and the

up and down. The tractor is stationary during folding.

rotor arm joints.

4

5

27

Rotary tedders 09/13 |

Going forward and in reverse

Thanks to the outstanding axle concept,

these rotary tedders are highly nimble and

easy to maneuver. To reverse, the free-

pivoting wheels simply swivel around. Then

the rigid wheels in the center take over for

machine guidance, giving a ride quality

similar to that of a tandem axle trailer.

Quietest running

The eccentric adjuster

Convenient

Maintenance-free permanent brakes

Setting the angle of throw from

The reversing valve controls the

and large 18/8.50x8 tires on the three

14° to 19° is easy and fast using

border spreading facility, the

castering wheels - this is the level of

an

eccentric ring on the wheel

position of the wheels and the wings

specification that brings

quietness

assembly.

from the tractor seat. The tractor

to running, even at

40 km/hr

requires only one double-acting

(25 mph).

hydraulic coupler.

28

| Rotary tedders 09/13

1. Small rotors

1

Each rotor has six tine arms to ensure uniform spreading. Drive power

flows smoothly through liquid-grease gearboxes and OctoLink finger

clutches.

2. Perfect control

A leading, height-adjustable and castering wheel is an option to optimize

ground hugging in any terrain.

3. Not need to leave the cab

The models KW 13.02/12 T and KW15.02/14 T are available with

an optional electric control. Simply toggle a switch to select border

spreading or the machine folding function.

2

4. Hydraulic border spreading system

This is base specification on KW 13.02/12 T and KW 15.02/14 T. The

system allows the tedder to run at an angle behind the tractor and still

throw the material consistently across the full work width from the border

towards the middle of the field.

3

4

29

Rotary tedders 09/13 |

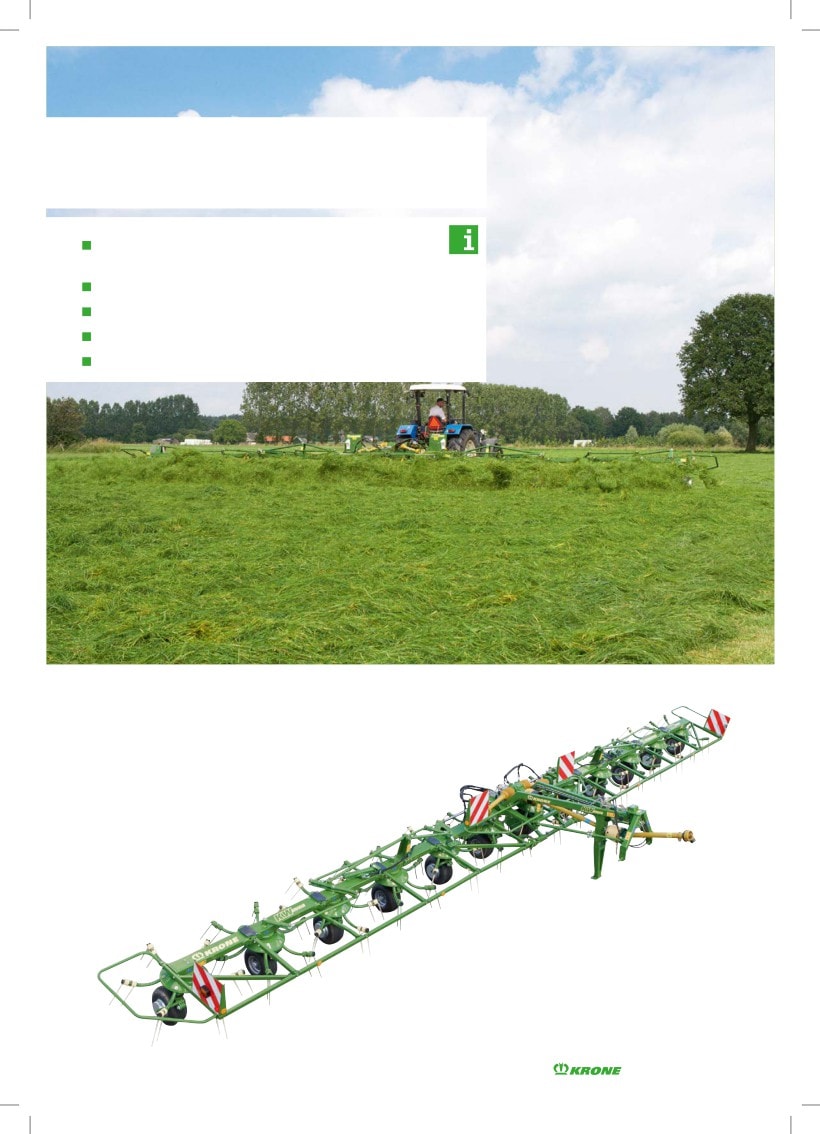

Getting serious

KWT 1600, KWT 2000

These machines work at widths of staggering 16 / 20 metres

(52'6" / 65'7") - in every single pass

Excellent spread pattern from small-diameter rotors

Heavy-duty beams

Maintenance-free OctoLink clutches on the rotors

Intelligent steering, no damage to the sward

Stepping up the rate

The trailed KWT 1600 and KWT 2000 rotary tedders not

strong 9.5 mm (0.4") double tines of different lengths

only deliver impressive acreages but also the best quality

attached to massive tubular steel arms, a sturdy frame

of work. 14 or 18 rotors spread the forage in an extremely

with sections offering individual adjustment and a wide

consistent mat. The individual sections respond flexibly

transport running gear running on oversize wheels - all

to ground undulations for effective ŧedding across the

these features combine to deliver dependable results

full work width. Permanently

lubricated

gearboxes, and highest work rates for many years to come.

30

| Rotary tedders 09/13

Sweeping success

Making quality forage not only requires a high-

capacity mower but also the tedder to match.

Rotary tedders work best at slower

ground speeds and so huge widths

become increasingly popular. A KWT 1600

or a KWT 2000 delivers work rates that compare to those delivered by high-capacity mower

combinations, following the mower to produce evenly wilted forage.

OctoLink:

Maintenance-free finger clutches

run in liquid grease gearboxes

on KWT

1600 and KWT

2000,

withstanding the highest strains and

providing

unsurpassed

longevity.

Small rotors

Small-diameter rotors, six tine arms per rotor and

the robust double tines of varying lengths leave an

exemplarily uniform spread pattern.

31

Rotary tedders 09/13 |

Ultimate performance

Technology of ultimate perfection

Easy use

Auto-sequenced folding

Manual depth control on KWT 1600

Electro-hydraulic work depth control on KWT 2000

Independent ground contour following

The perfect solution

Hydraulic top link

Safe travel on the road

A linkage system lifts the KWT 1600

The hydraulic top link consistently

High-reflective and single-piece

and 2000 rotors hydraulically clear

maintains the set work depth. Its

side guards combine with effective

out of work and into transport or

task is to tilt the individual sections

lighting to increase road safety

headland position.

and the rotors

90° forward into

at night when entering roads or

transport position.

crossing traffic junctions.

32

| Rotary tedders 09/13

Titanic dimensions

shrink to a compact

transport package

Working at such staggering widths as 15.25 m

(50') and 19.60 m (64'4") and folding into a

narrow transport unit of less than 3 m (9'10"),

KWT 1600 and KWT 2000 not only impress

in the field but also on the road. Changeover

from work to transport position is easy and

convenient as auto sequence control takes out

the stress and helps boost daily outputs.

Sequence control in action

The rotors lift off the ground and the boom

sections raise clear and parallel with the

ground, which is easy thanks to an im-

pressive ground clearance that makes it

easy to cross ditches and field borders. In

‘headland position’, the machine not only

makes the turn but also manoeuvres in

corners and wedges. Once the rotors and

the frame are off the ground, the rotors tip

90° forward. Then the outer sections fold

in. Last, the folded booms swing to the

middle and settle on the frame, with rear

lights and reflective side guards folding

automatically into transport position.

33

Rotary tedders 09/13 |

Clever stuff

As the rotors lift out of work, a pretensioned spring

presses the drawbar to the ground, so the tractor‘s link

arms stay in position.

Spindle controlled

Depth on KWT 1600 is controlled from a threaded

spindle. When the depth is right, sweeps are clean and

tedding is effective.

Full adaptation

Elongated holes in the central boom section give the

central rotor the flexibility to follow the ground contours

irrespective of the transport gear‘s contouring and thus

ensuring thorough work in undulating terrain.

Uniform working depth

It is essential that all rotors work at an identical height.

The KRONE KWT 1600 and 2000 models feature boom

sections that offer eccentric adjustment. The system

ensures the high quality of work is maintained through-

out many years of operation.

34

| Rotary tedders 09/13

Perfect

The boom is made from extra strong steel that provides

the necessary stability to these huge widths. The

enclosed and extremely robust fan-type guard frame not

only complies with work and health safety regulations

but also takes load off the arms and joints.

Variable spreading angle

Setting the angle from 13 to 19 degrees is an easy job,

which is carried out quickly on a pin-and-hole system on

the wheel arm holders. The steep position is preferred

during tedding; the shallow position is best for turning.

Running on big boots

Big boots leave a softer footprint on soft ground,

are gentle on the sward and reduce compaction.

KWT 1600 runs on standard 19.0/45-17 or optional

500/50-17 tyres, whereas KWT 2000 is equipped with

standard 500/50-17 tyres and 550/45 R22.5 rubber.

Electro-hydraulic

The base level KWT 2000 models feature electro-

hydraulic depth control from the Delta terminal or the

CCI terminal, each offering convenient adjustment on

the go and from the tractor cab.

35

Rotary tedders 09/13 |

A KRONE exclusive!

The steered transport running gear

In transport mode, the gear tracks perfectly

behind the tractor - giving tightest turns

In work mode, the gear aligns with the rotor wheels -

for optimum castering on headlands

Protecting the sward from damage and the tyres from excessive wear

Automatic transport / work changeovers

Gentle on the sward

KWT 1600 and KWT 2000 not only impress by delivering aligning with the rotor wheels in the field, any risk of

enormous work rates but also by an exemplary agility

scuffing is eliminated.

in awkwardly shaped fields. With the transport wheels

36

| Rotary tedders 09/13

Intelligent steering

The caster-steer transport running gear easily manages tightest turns, provides greatest

manoeuvrability and best castering on the road and in the field. Depending on the current

position of the rotors, it is the selected field/transport mode that steers automatically the large

caster transport wheels. To suit, the axles on KRONE KWT 1600 and KWT 2000 meet the highest

user demands.

Tracking behind the tractor

The transport wheels are tracking accurately behind the

tractor when the booms fold in for road travel or lift out

during headland turns.

Following the rotor wheels

Vice versa, the transport wheels are following the

wheels on the lowered booms when the combination is

travelling around bends in the field.

Flexible steering:

The forced-steer transport running gear provides two

different configurations that ensure the wheels perform

perfectly all the time, whether on the road, the headland

or in work. The configuration is altered hydraulically and

automatically as the frame sections are folding in or out.

37

Rotary tedders 09/13 |

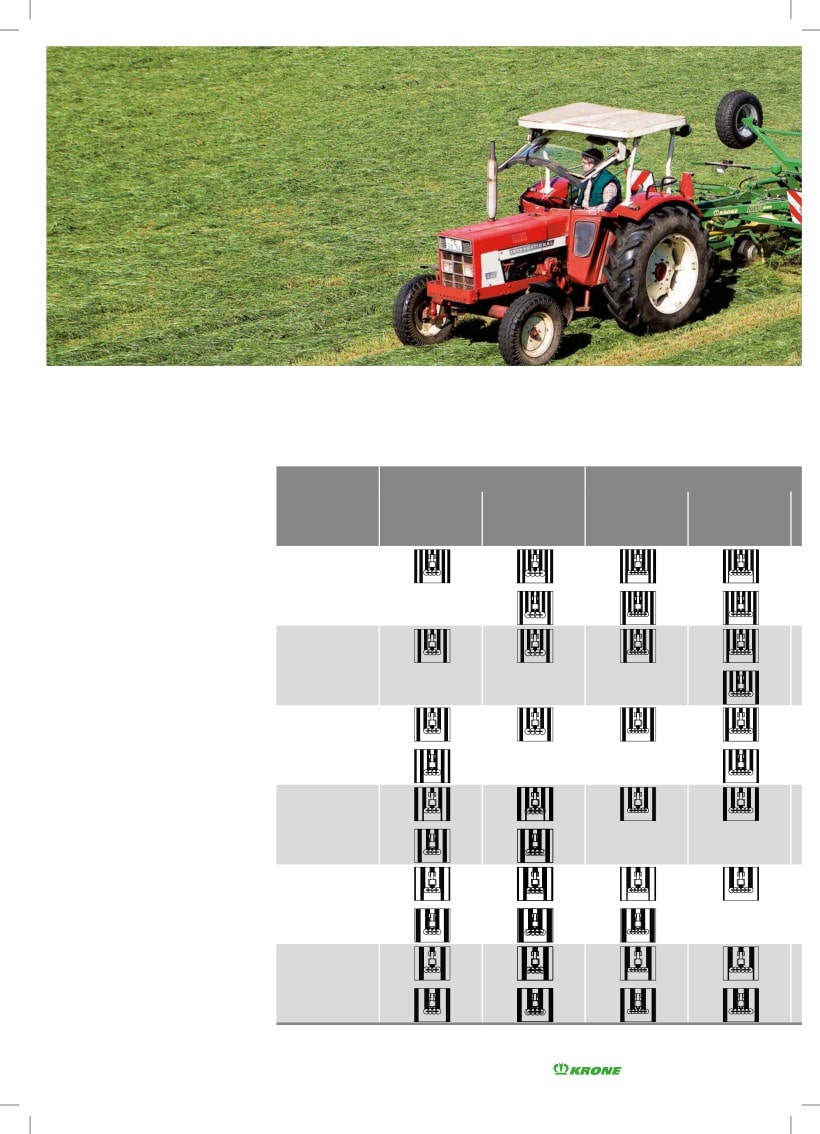

The right tedder to match your mower

You get optimum results when

Mower widths

4 rotors

6 rotors

one windrow is agitated by two

(m)

KW 4.62 / 4

KW 5.52 / 4 x 7

KW 6.02 / 6

KW 6.72 / 6

rotors and when the tractor is

KW 5.52 / 4 x 7 T

not running on the windrows.

1.50

- 1.70

(4'11" - 5'7")

1.80

- 1.90

(5'11" - 6'3")

2.00

- 2.25

(6'7" - 7'5")

2.40

(7'11")

2.80

(9'2")

3.20

(10'6")

38

| Rotary tedders 09/13

8 rotors

10 rotors

12 rotors

14 rotors

KW 7.82 / 6 x 7

KW 7.92 / 8

KW 8.82 / 8

KW 11.22 / 10

KW 13.02 / 12 T

KW 15.02 / 14 T

KW 7.82 / 6 x 7 T

KWT 8.82 / 8

KWT 11.22 / 10

KWT 1600

KWT 7.82 / 6 x 7

39

Rotary tedders 09/13 |

Technical Data

Three-point mounted rotary tedders

KW 4.62 / 4

KW 5.52 / 4 x 7

KW 6.02 / 6

Work width to DIN 11220

mm

4,600 (15'1")

5,500 (18'1")

6,000 (19'8)

Acreage

Approx. ha/h

4.6

5.5

6

(acres/hr)

(11.4)

(13.6)

(14.8)

Transport width

mm

2,690 (8'10")

2,980 (9'9")

2,690 (8'10")

Storage height

mm

2,400 (7'11")

2,680 (8'9.5")

3,120 (10'3")

Min. power requirement

Min. kW/hp

25/34

37/50

37/50

Weight

Approx. kg

570

680

750

(1,256.6 lbs)

(1,499.1 lbs)

(1,653.5 lbs)

No. of rotors

4

4

6

No. of tine arms per rotor

6

7

5

Tire size

16/6.50x8

16/6.50x8

16/6.50x8

–

-

-

Border spreading system

mech.

mech.

mech.

(hydr. option)

(hydr. option)

(hydr. option)

Attachment category

Cat I/II

Cat II

Cat II

Hydraulic couplers

1 sa

1 sa

1 sa

Angle of throw

13° - 19°

13° - 19°

13° - 19°

40

| Rotary tedders 09/13

KW 6.72 / 6

KW 7.82 / 6 x 7

KW 7.92 / 8

KW 8.82 / 8

KW 11.22 / 10

6,700 (22')

7,800 (25'7")

7,900 (25'11")

8,800 (28'11")

11.000

6.7

7.8

7.9

8.8

11

(16.5)

(19.3)

(19.5)

(21.7)

2,850 (9'4")

2,980 (9'9")

2,980 (9'9")

2,850 (9'4")

2980

3,400 (11'2")

3,580 (11'9")

3,150 (10'4")

3,450 (11'4")

3750

44/60

48/65

48/65

55/75

66/90

860

980

1,090

1,180

(1,896 lbs)

(2,160.5 lbs)

(2,403 lbs)

(2,601.4 lbs)

6

6

8

8

10

6

7

5

6

6

16/6.50x8

16/6.50x8

16/6.50x8

16/6.50x8

16/6.50x8

-

-

-

18/8.50x8 (middle)

18/8.50x8 (middle)

mech.

mech.

mech.

mech.

hydr.

(hydr. option)

(hydr. option)

(hydr. option)

(hydr. option)

Cat II

Cat II

Cat II

Cat II

Cat II

1 sa

1 sa

1 sa

1 sa

2 x DW

13° - 19°

13° - 19°

13° - 19°

13° - 19°

13° - 19°

Absolutely safe

Perfecting the system

Lighting is safer

The optional free-running clutch on the

Optional extensions for the tractor’s link

The three-point linkage machines are

main driveshaft is useful on machines

arms and top link are available so the

available with a lighting system for safe

up to 6.70 m (22') in width. It is operated

tractor can raise the mounted equip-

road travel at night.

by a tractor with pto brake, where it

ment higher. Besides, longer link arms

offers maximum safety when shutting

increase the space between the tractor

off the machine.

and the machine, a boon on tractors

41

using big rear wheels.

Rotary tedders 09/13 |

Technical Data

Trailed rotary tedders

KW 5.52 / 4 x 7 T

KW 7.82 / 6 x 7 T

KWT 7.82 / 6 x 7

KWT 8.82 / 8

Work width to DIN 11220

mm

5,500 (18'1")

7,800 (25'7")

7,800 (25'7")

8,800 (28'11")

Acreage

Approx. ha/h

5.5

7.8

7.8

8.8

(acres/hr)

(13.6)

(19.3)

(19.3)

(21.7)

Transport width

mm

2,980 (9'9")

2,980 (9'9")

2,980 (9'9")

2,980 (9'9")

Storage height

mm

2,680 (8'9.5")

3,130 (10'3")

3,640 (11'11")

3,530 (11'7")

Min. power requirement

Min. kW/hp

18/25

37/50

37/50

37/50

Weight

Approx. kg

680 (1,499.1 lbs)

1.030 (2,270.7 lbs)

1.280 (2,821.9 lbs)

1,480 (3,262.8 lbs)

No. of rotors

4

6

6

8

No. of tine arms per rotor

7

7

7

6

Tire size

18/8.50 x 8

18/8.50 x 8

16/6.50 x 8

16/6.50 x 8

-

-

18/8.50 x 8 (middle)

18/8.50 x 8 (middle)

Tire size on running gear

-

-

10.0/75-15.3

10.0/75-15.3

Trailed

Swinging drawbar

Swinging drawbar

Tractor link arms

Tractor link arms

(Swinging drawbar)*

Border spreading system

mechanical

mechanical

hydraulic

hydraulic

Attachment category

-

Cat. II

Cat. II

Cat. I / II

Hydraulic couplers

1 sa

1 sa

1 sa

1 sa

Angle of throw

13° - 19°

13° - 19°

13° - 19°

13° - 19°

Air brake

-

-

-

-

Hydraulic brake

* not available in some markets

That’s possible too

Narrow windrowing gearbox

Some farmers prefer making narrow windrows so that the crop absorbs less

This optional gearbox is simply pushed

moisture during the night and dries out faster.

on the shaft and reduces the rotor speed

to produce narrow night windrows.

42

| Rotary tedders 09/13

KWT 11.22 / 10

KW 13.02 / 12 T

KW 15.02 / 14 T

KWT 1600

KWT 2000

11,000 (36'1")

13,100 (43')

15,250 (50')

15,250 (50')

19,600 (64'4")

11

13

15

15

18 -20

(27.2)

(32)

(37)

(37)

(44.5-49.5)

2,980 (9'9")

2,880 (9'5")

2,880 (9'5")

2,980 (9'9")

2,980 (9'9")

3,700 (12'2")

1,350 (4'5")

1,350 (4'5")

2,800 (9'2")

2,900 (9'6")

40/55

44/60

51/70

60/80

80/110

1,770 (3,902.1 lbs)

1,870 (4,122.6 lbs)

2,110 (4,651.7 lbs)

3,490 (7,694 lbs)

4,950 (10,912.8 lbs)

10

12

14

14

18

6

6

6

6

6

16/6.50 x 8

18/8.50 x 8

18/8.50 x 8

18/8.50 x 8

18/8.50 x 8

18/8.50 x 8 (middle)

16/6.50 x 8 (middle)

16/6.50 x 8 (middle)

10.0/75-15.3

-

-

19.0/45-17 (500/50-17)

500/50-17 (550/45-22.5)

Tractor link arms

Tractor link arms

Tractor link arms

Tractor link arms

Tractor link arms

hydraulic

hydraulic

hydraulic

-

-

Cat. I / II

Cat. I / II

Cat. I / II

Cat. II

Cat. II

2 da

1 da

1 da

2 da

1 da

13° - 19°

14° - 19°

14° - 19°

13° - 19°

13° - 19°

standard

–

-

-

-

option

Spare wheel

Anti-wrap guards

Genuine spare parts pay dividends

Stored on a holder supplied with the

Optional plates are available for attach-

User experience and tests conducted

wheel, the spare is easy to remove

ment to the wheel holders that protect

by agricultural magazines have shown

without tools.

the wheels from wrapping sticky forage.

that manufacturer-tested quality parts

last longer. Do not compromise on

quality; trust in Original KRONE parts.

43

Rotary tedders 09/13 |

Internet

Discover the world at KRONE and browse through our website pages

to find facts and figures and also new developments plus a wide range

of services. Explore our website and find out how versatile the KRONE

world is.

News

Service

Click here to find up-to-the minute information about KRONE -

Here you find all the service information you require - from

from new product presentations to show reviews. Here you are

a point of contact at the factory to finance schemes for your

at the pulse of KRONE life.

KRONE machine as well as training schemes for staff and users.

Products

Find extensive information on our full product range. This section

Download Center

holds everything you need - from video clips to manuals.

Are you looking for a KRONE calendar for your desktop or a

smart picture for your presentation? Here, at the KRONE

download center, you will find plenty of useful material for a wide

Sales organisation

range of projects.

Here you find a distributor in Japan as well as your local KRONE

dealer who will be pleased to support you. This is where you find

Used Machinery

your KRONE partner who will be pleased to assist you.

KRONE often has a wide range of demonstration or exhibit

machinery on offer. This is a good site to find your KRONE

Jobs

machine. Then contact your local KRONE dealer to arrange the

Would you like to join our company? KRONE is often looking

details of a potential purchase.

for diligent and motivated staff to work at our farm machinery

factory as well as at our commercial trailer production plant. So,

Parts

this section is always worth a visit.

24 / 7... This service gives you the opportunity to find your

KRONE part at any time and without waiting. The KRONE Agro-

Media center

parts Portal has an article number and exact description for

The KRONE ‘database’ holds thousands of documents, pictures,

every part. You can order the part instantly at your local KRONE

test reports and much more. Here you find very detailed

dealer by sending an e-mail to Agroparts.

information on KRONE products that are of special interest to

you.

KRONE shop

Are you looking for a gift or are you a collector of farm models?

Events

Then you should definitely shop around at our KRONE shop. We

Are you in for a KRONE live experience? Check out for KRONE

take your orders at any time of the day.

events and look at a machine on show or watch it during a

demonstration. After all, there is little that is more effective than

a hands-on experience.

Your KRONE dealer

Maschinenfabrik Bernard KRONE GmbH

Heinrich-Krone-Straße 10

D-48480 Spelle

Telefon: +49 (0) 5977. 935-0

Telefax: +49 (0) 5977. 935-339

info.ldm@krone.de