The rotor

Depend on it

Design and functionality of a sealed rotor

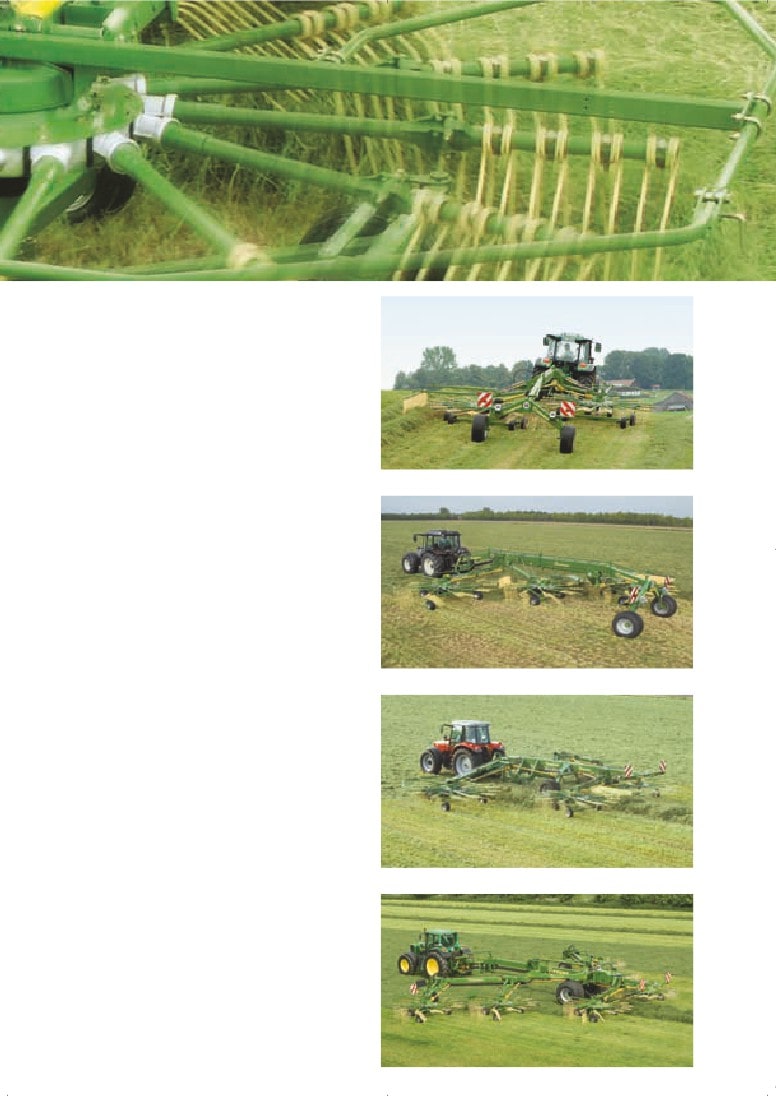

Swadro 35, 38, 42, 46

Three-point linkage single-rotor rake working at widths from

3.50 m (11'6") to 4.60 m (15'1")

Swadro 38 T, 42 T, 46 T

Trailed single-rotor rake working at widths from 3.80 m (12'6")

to 4.60 m (15'1")

Swadro 700, 800/26, 900,

700 Plus, 800/26 Plus, 900 Plus,

1000

Trailed two-rotor center-delivery rake working at widths

from 6.80 m (22'4") to 10.00 m (32'10").

Swadro 710/26 T

Trailed twin-rotor side-delivery rakes working at widths of

6.20 m (20'4") in single windrow presentation or at widths

of 2 x 3.40 m (2 x 11'2") in double windrow presentation

Swadro 807, 810, 907

Trailed twin-rotor side-delivery rakes working at widths from

6.20 m (20'4") to 8.00 m (26'3") for single windrow presentation

Swadro 810 offers an extra setting option for double windrow

presentation from 2 x 3.70 m (2 x 12'2") in one pass

Swadro 1010

Trailed triple-rotor side-delivery rake working at

9.70 m (31'10") width

Swadro 1400, 1400 Plus

Trailed four-rotor center-delivery rake working at widths from

11.00 to 13.50 m (36'1" - 44'4")

Swadro 2000

Trailed six-rotor center-delivery rake working at widths from

10.00 m to 19.00 m (32'10" - 62'4")

One can count on

In order for work to run smoothly in the field, competent

Fluid grease filled

preliminary construction work must have been performed.

rotor drive gearboxes

High quality, excellent workmanship and innovative details

Enclosed rotor housings:

completely maintenance-free

are characteristic for all KRONE products. Of course, this

Rotor and tine arms free of

is also true for the Swadro model rotary rakes - the name

grease nipples

synonymous for performance and

Dura-Max, the double

hardened cam track

smooth output.

Tine arms with extra strong

profile tube

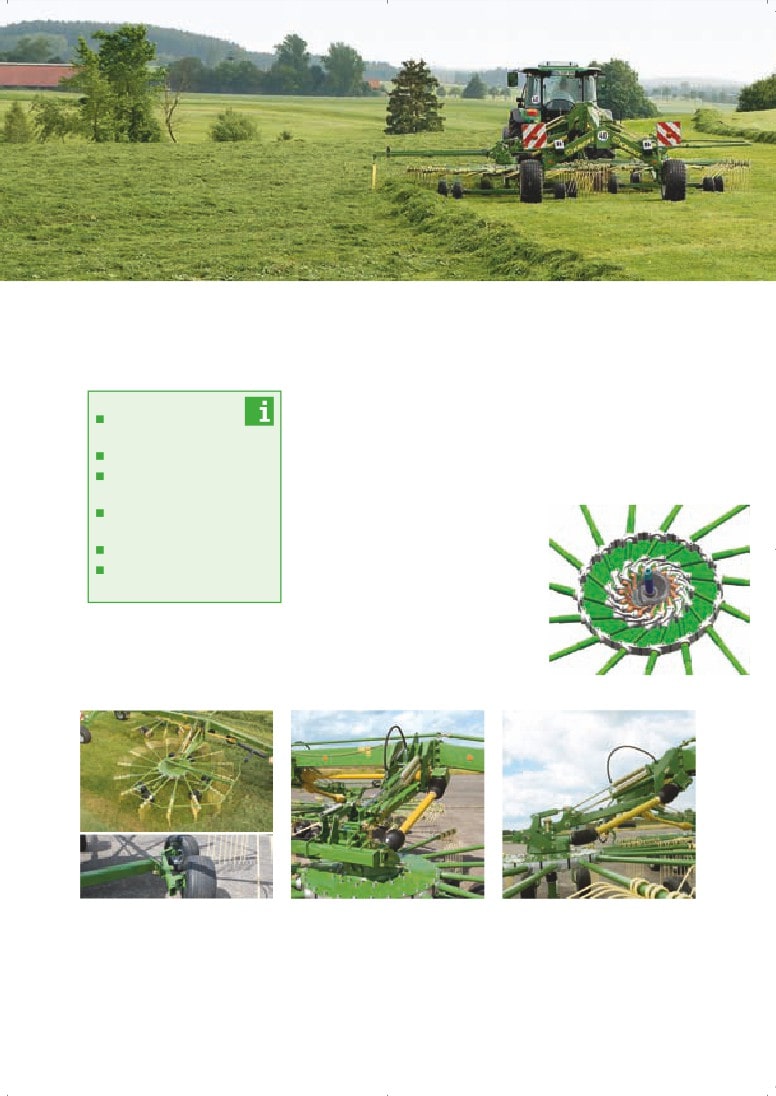

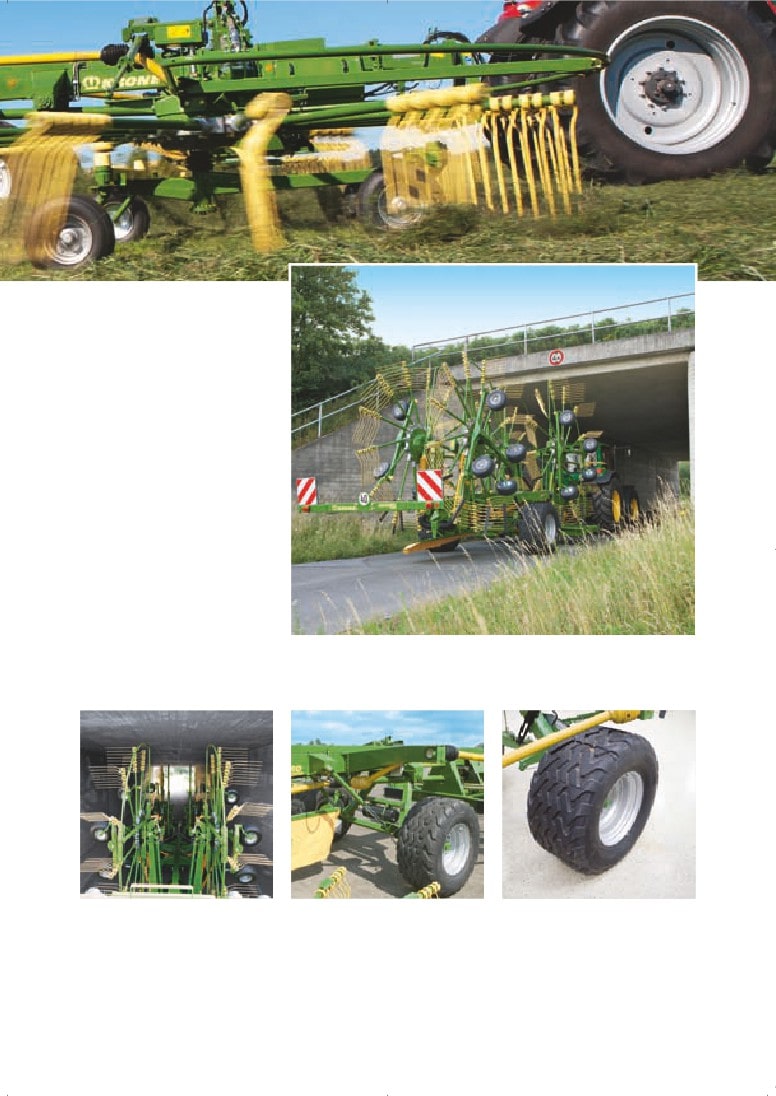

Dura-Max: the cam-track, double harde-

For perfect swathing: the control of the tine

Innovative: the tine mounting bearing cases

ned and impact resistant strength, is made

arms is performed via large dimensioned,

are made of aluminium. This saves weight

from Bainite-hardened cast iron to ensure a

sealed for life cam follower rollers. The

and still guarantees the highest of rigidity.

high abrasion resistance while being

contour of the cam track stands for smooth

The large spacing between the grooved

completely maintenance-free. This cam-

performance and exemplary formed box-

ball bearings increases load capabilities - a

track comes with a three-year warranty.

shaped windrows.

clear advantage when in heavy crops.

4

Grease nipples on the gearbox, the

cam-track, or on the tine arms? No

thank you! KRONE rotary rakes not

only provide an optimum of perfor-

mance, but of course, also where

maintenance is concerned, the cam-

track, cam follower rollers and the tine

arm bearings all operate in a enclosed

housing and require no maintenance.

The Dura-Max special hardened cam-

track, the large cam follower rollers,

the extra strong tubular tine arms and

their bearings in aluminium housings

are built to withstand the highest of

forces in heavy forage and thus

increase profitability.

Quick and simple: assembly and disassem-

Cleanest sweeps - up to five double tines

Maintenance-free and continuously

bly of the complete tine arm with bearing

on each tine arm give a trailing action for

lubricated: The Swadro rotors are driven via

and cam follower roller. After removing only

cleanest rakes. Thick-walled arms and up

completely enclosed, liquid grease filled

two bolts the complete unit can be pulled

to 10.5 mm (0.4") tines plus large-diameter

bevel gear drives. This ensures uniform and

out of the rotor. The removal of two hollow

coils combine to guarantee outstanding

optimum lubrication and further lubrication

roll pins means that the outer end of the

longevity, flexibility and strength.

via a grease gun is not necessary.

arm can also be exchanged.

5

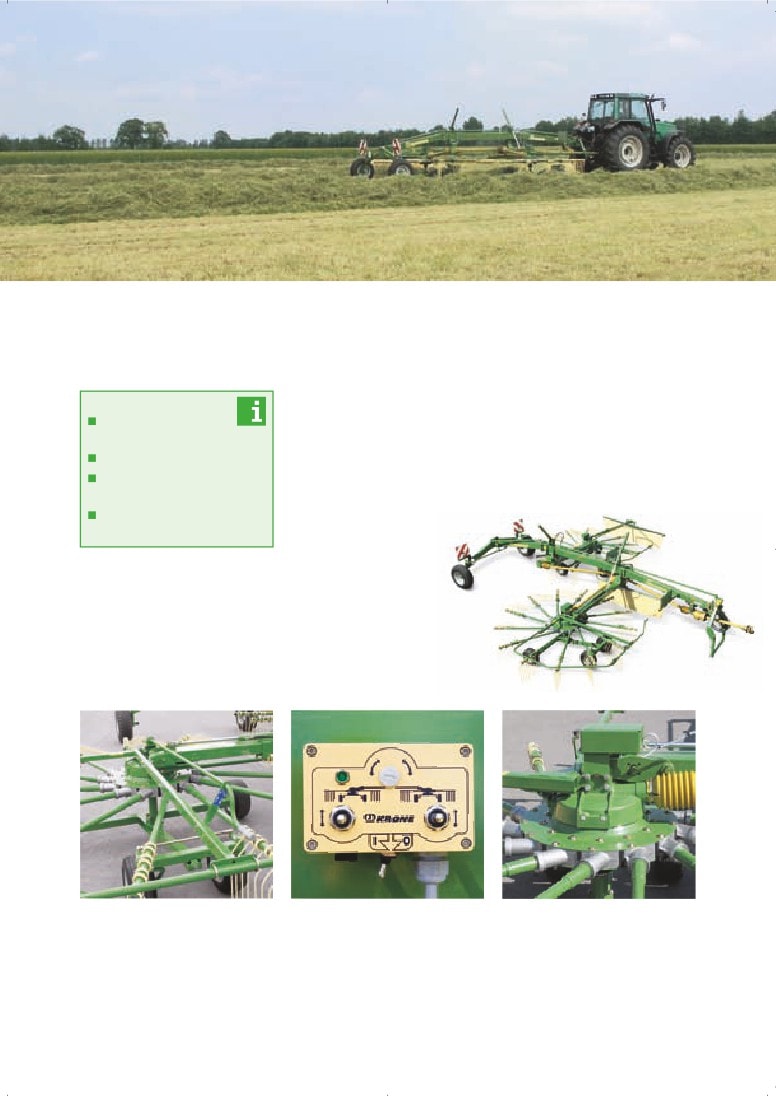

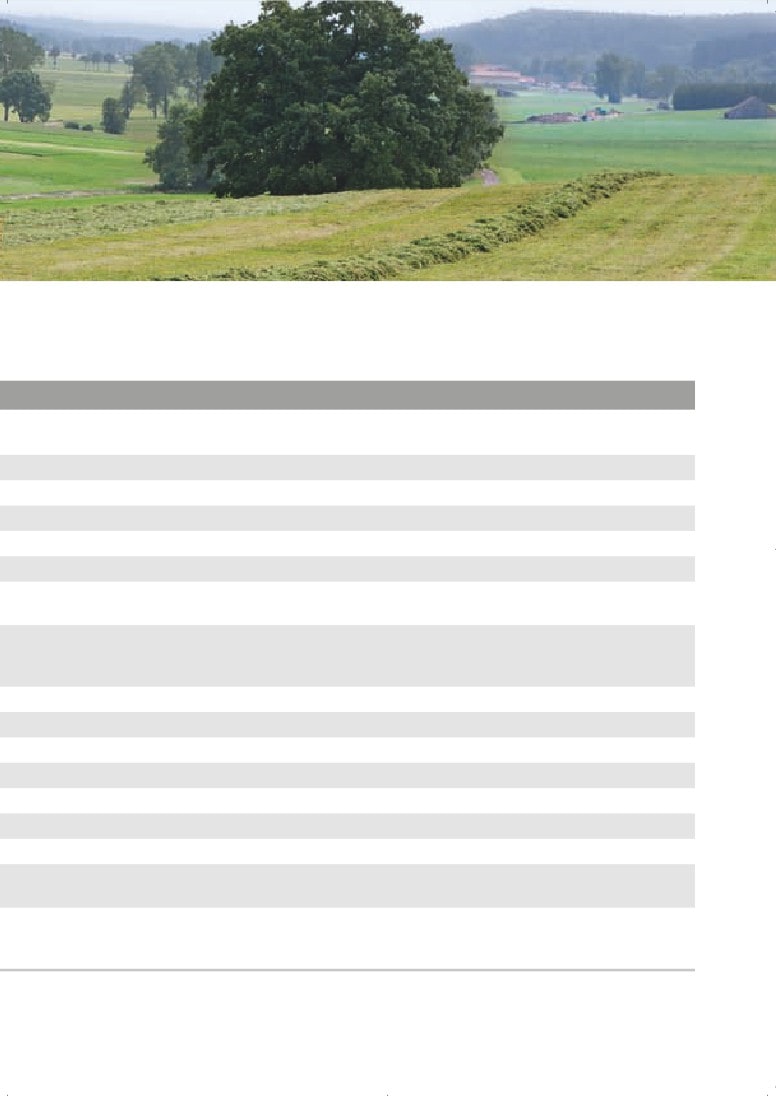

SWADRO 35, 38, 42, 46

Three-point linkage mounted Single Rotor Rakes

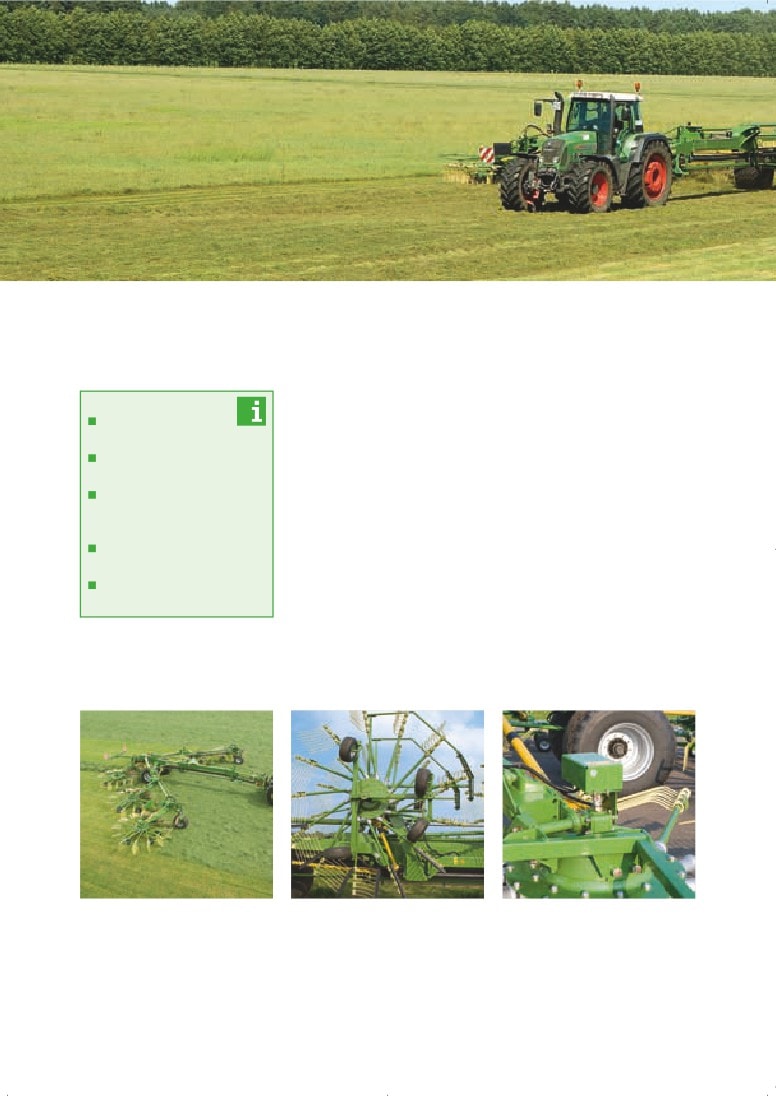

Feels at home in many applications: the three-point linkage

Tandem axle as

mounted Swadro single rotor rakes with working widths of

standard equipment

3.50 m to 4.60 m (11'6" to 15'1"). Their exemplary robustness

Shock absorbing link-rods

and unique technology are convincing and offer many of the

with interior compression

springs

technical features proven

Self-centralizing when raised

in the KRONE large-scale

Fold-in tine arms

rakes.

On big tires: the Swadro single rotary rake

This one balances out: the Swadro single

Absolutely clean. Nothing is left behind on

is optimally equipped with its 16 x 6.50, 6

rotary rakes have a tandem axle as stan-

the ground, not even in heavy silage. A

ply super balloon tires. These tires offer

dard equipment with the wheels mounted

pin/hole setting system adjusts rotor tilt on

excellent running and soft treading to

as close to the rotating tines as possible.

either side of the rotor.

protect the turf.

This guarantees the best contour following

and cleanest raking on uneven ground.

6

It starts with the running gear: The

larger the rotor diameter the more

important the running gear becomes.

For clean raking the tines must travel

across the entire working width at a

uniform height above the ground.

Ground unevenness or ridges may

cause forage contamination, which in

turn can lead to a severe deterioration

in silage quality. For this reason

KRONE offers balanced tandem axles

as standard equipment on its range of

single rotor rotary rakes. For a much

improved contour following a front

support wheel is available as optional

equipment.

Perfect in work: using up to 13 tangentially arranged tine arms, the SWADRO 35 to 46

single rotor rakes deposit the crop in clean, even swaths.

Perfectly guided: an additional, height

Optimally controlled: different top link pin

Easy adjustment: the final adjustment of

adjustable castor support wheel is available

positions ensure the optimum guidance of

the working height of the rotor is infinitely

as an option so that when fitted the rotor is

the rotor under any condition. When utili-

adjustable. This is being done quickly and

aligned even better to the ground contours

sing the front support wheel the elongated

easily from the tractor seat by means of a

especially on undulating ground.

hole is chosen for the top link for additional

crank handle. The result is clean crop trans-

float potential.

fer without anything left behind.

7

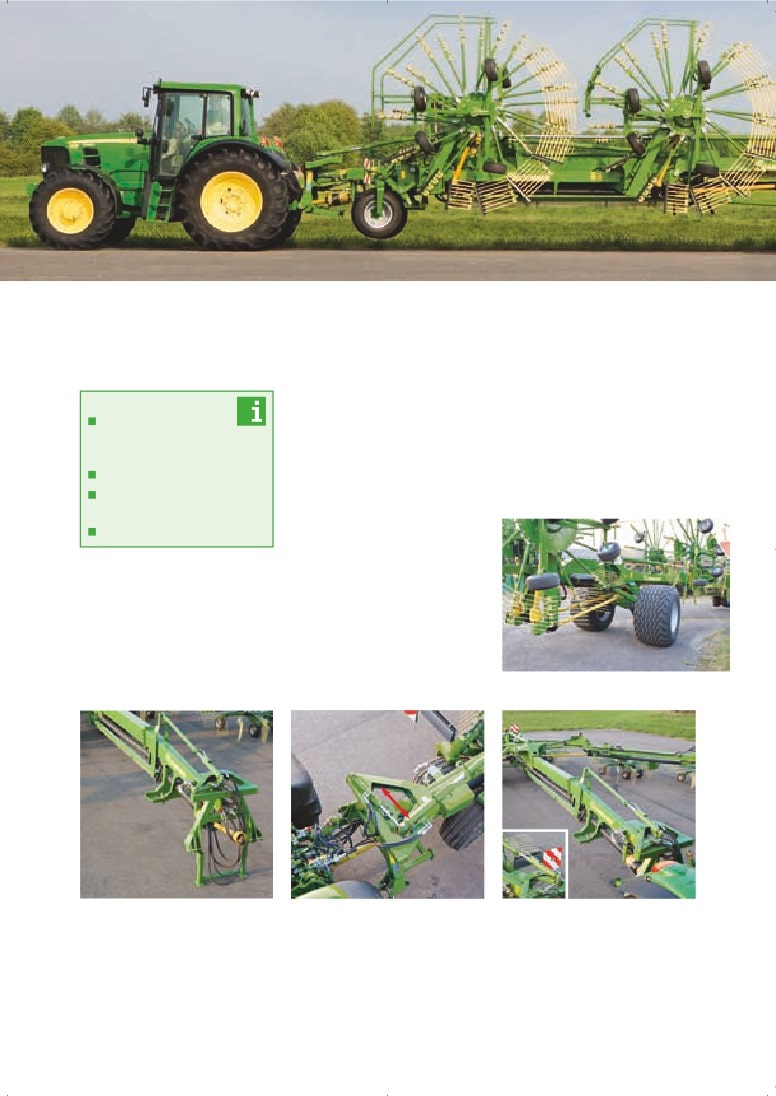

Flexible and agile. This rake does a

clean job. With a steering angle of 20°

the corners are also covered as the

following rotor will not miss anything

forming perfect windrows, even in the

corners. This is a key advantage,

because KRONE Swadro single rotor

rakes are often utilized in small,

winding fields.

Tracks true: In any curve KRONE Swadro single rotor rakes always follow the tractor.

Always the optimal windrow width: the

Exclusive: The patented tracking system

Damped is better: shock-absorbing link

adjustment of the swath curtain is simple.

steers the KRONE rakes through the

rods ensure a smooth trailing action under

Depending not only on the heaviness of the

tightest turns. A swing combined with

all conditions, in curves, at high speeds, as

crop, but also on the desired windrow

accumulator arms implements a steering

well as when raking downhill.

width, the swath curtain can easily be

angle of about 20° for excellent maneuve-

extended or retracted via a telescopic link

rability and large lift-out height.

arm.

8

Safe on the road: high traffic volumes

and faster tractor speeds make high

demands on mounted machinery with

regard to traffic safety. KRONE rakes

meet these demands fully. With folded

tine arms and a fold-away swath

curtain Swadro single rotor rakes are

quite compact and can be converted

for road transport quickly and safely.

Competent in the field, compact on the road: these properties are characteristic of all rotary

rakes from KRONE.

Comfortable and automatic: the machine

Practical: a large over-dimensioned tension

Easy as pie - wide in the field, narrow on the

is lifted for transport. For this purpose, the

spring eases the lifting of the swath curtain

road: the outer tine arms are folded in for

shock-absorbers come to a stop and

up into the transport position. Simultaneous-

road transport. This is done quickly and

secure the rotor in the center position

ly, the rotor is prevented from turning by a

easily - effortlessly.

behind the headstock. No securing the rake

locking strap. This ensures the low transport

by hand is necessary.

width with its laterally folded tine arms is

maintained.

9

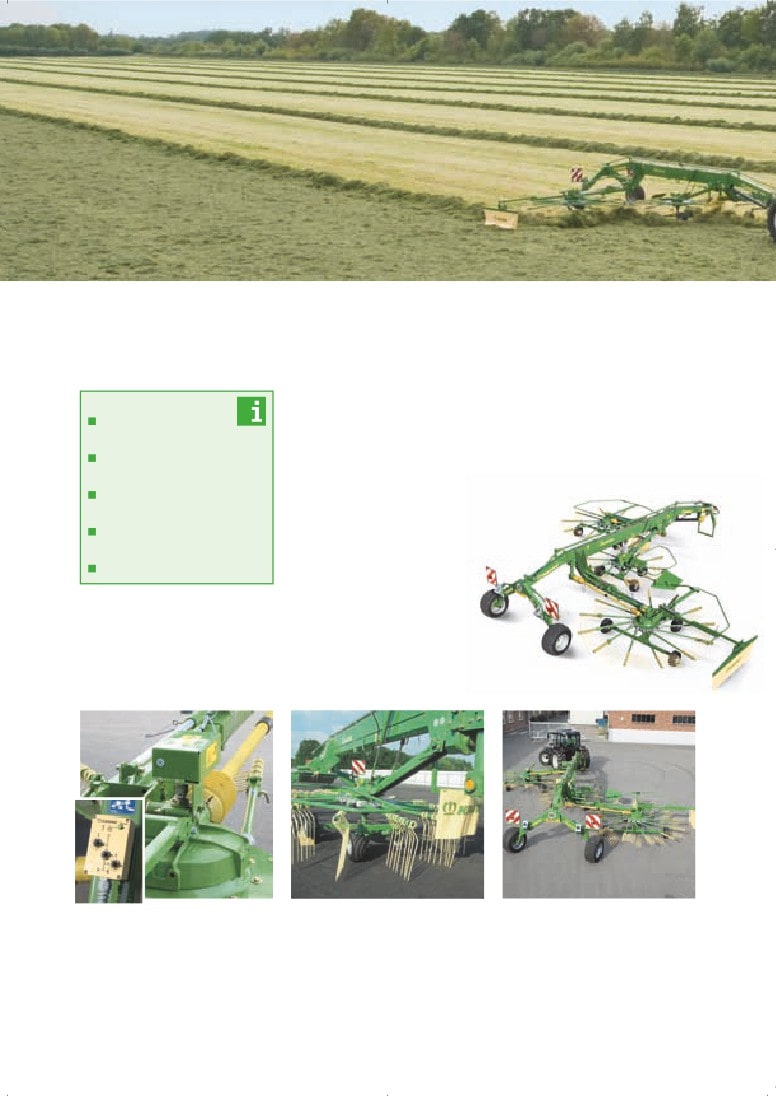

Swadro 38 T, 42 T and 46 T

Trailed single-rotor rakes

KRONE added the Swadro 38 T, 42 T and 46T models to

Large working width

its range of rakes to meet farmer demands at home and

Low power requirement

abroad. The demand is for a trailed and well-proven

Drawbar with parallelogram

control

single-rotor rake that offers the well-proven Swadro

Easy hitching on and off

technology. The tandem axle

Tandem axle with 18" tires as

standard equipment

on these models serves

Swadro 38 T and 42 T are

also as transport running

marketed in export markets

only

gear on public roads.

Jammed on the drawbar? This won’t

Aiming high: the lifting of the rotor is done

Everything is picked up: the adjustment of

happen with the parallelogram controlled,

hydraulically. The construction of the

the working height is simple and is done via

height adjustable drawbar for the tractor

tandem running gear and the lifting cylinder

extendable, adjustable supports where a

drawbar or pick-up hitch. The hydraulic

linkage means a high ground clearance of

simple pin and clip is slipped into a series

ram on the drawbar levels the rotor during

around 600 mm (2') - ideal for driving over

of holes.

lift and lowering.

already deposited windrows.

10

The output of a single-rotor rake is not

limited by lack of pto power but by the

fact that the machine takes too much

load off the tractor's front axle as it is

raised out of work. The answer to this

problem is Swadro 38 T, 42 T and 46 T.

These trailed models suit small and

light tractors and applications in

sloping fields. They stand out for low

tractor power input and easy attach-

ment and removal - either via floating

or linkage drawbar.

Quickly and safely down the road at 40 km/h (25 mph): this can also be achieved with a

small tractor. The machine does not affect tractor steering. No load is taken off the front

axle.

The tandem axle with large dimensioned

For the best results when raking in all

Narrow transport width: The tine arms on

18" super balloon tire as standard

conditions: the optional front support

the sides of Swadro 46 T fold up easily to

equipment: Even in heavy forage crops

wheel. It trails - which is ideal for tight cur-

provide a compact transport width and safe

everything is picked up, the transverse

ves. The working height can be easily

travel.

rotor angle can also be fine-tuned via a

adjusted with a pin adjustment in a hole

spindle.

segment.

11

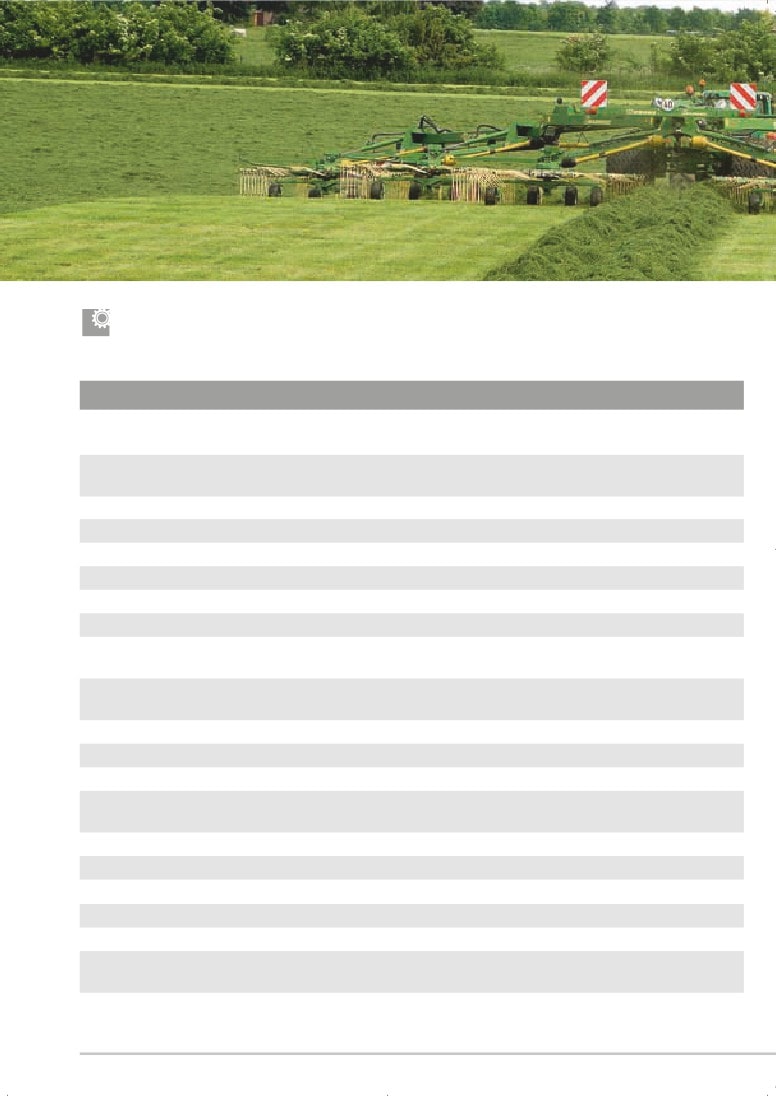

Swadro 700, 800/26, 900

The professional center delivery Rakes

In order for work to run smoothly in the field, competent design

KRONE-Jet-Effect

and build quality must be right from the start. With KRONE you

Cardanic rotor suspension

can rest assured that you will always have to hand first-rate

Choice of mechanical or

machinery, the technology of which is impressive. This is also

hydraulic work width control

true for the KRONE center delivery rakes with working widths of

on Swadro 800/26 and 900

Separate rotor lift/lower

6.80 to 8.80 m (22'4" to 28'11"). They are easy to service and

feature on Swadro 800/26

maintain, work-hungry, yet gentle

and 900

on both forage and swath.

The basis for a long service life: The Cat I

A single axled undercarriage for the Swadro

Wide track: the tridem axle is gentle on the

and II lower link hitch points are solidly

700 with 18 x 8.50 - 8/6 PR-RT tires comes

swath and makes for clean forage. The

designed and the headstock connected via

as standard equipment: the large tires of

front wheels are castor-steered and

the pendulum suspension. The PTO shaft

the extra wide axle run closely to the

connected to a track rod. This results in

cannot be damaged by inadvertently lifting

working tines, which is ideal for clean

smooth running whereas the fixed rear

the lower link arms.

raking.

wheels stabilize the driving behavior on

slopes.

12

Gentle and efficient: a center delivery

rake provides advantages, where forage

quality is concerned. It operates in a

very clean fashion, because the forage

is handled from both sides only across

one rotor width. The box-shaped,

extremely uniform windrows are ideal

for feeding into following harvesting

machinery. With a center delivery rake,

one can drive fast and achieve a large

raked area. The Swadro 900 with its big

diameter rotors and 13 tine arms on

each is a high output machine easily

attaining work-rates of approximately

8.5 hectares (21 acres) per hour. The

Swadro 700, 800, and 900 are highly

Clean: because the forage is handled by only one rotor. KRONE Swadro twin rotor center

impressive with their simple operation,

deliver rakes deposit the forage in an airy, loose manner without any roping.

very good driving and tracking proper-

ties and their compact, clearly arranged

design.

Adjusting rotor tilt: Rotor depth is adjusted

Cornering smoothly - castering rear wheels

Perfect guidance

- extra wheels are

on depth holes. The system is easy to

are available as an option for the tridem

available as an option for the tridem axle to

handle and sets the depth separately on

axles. Tracking excellently in headland

allow the rear axle to run like a tandem

the rear wheels of the tridem axle. As a

turns, these wheels eliminate the risk of

assembly, hugging the ground and

result, nothing is left behind, even in the

scuffing, protect the turf and take off stress

enabling cleanest rakes from large rotors.

heaviest crop

from the running gear.

13

The KRONE Jet Effect: clean landing,

clean start! The trailing rotor linkage,

combined with the cardanic

suspension, makes perfect sense: as

when the rotor is lowered, the rear

wheels of the tridem axle touch the

ground first and then the front wheels

- when lifting this occurs in the reverse

order. This is why the tines are unable

to drop into the ground, damaging the

windrow or contaminate the forage

during the lowering and lifting process.

This KRONE solution guarantees high

quality forage.

Using equal ground pressure across the entire width: because the rotor is suspended from

Trailing rotors: The rotor mounts in a positi-

a central position over the main rotor gearbox the tines leave the ground parallel to the

on behind its arm. This design combines

transverse driving direction during lifting. The result: central suspension stands for clean

with its cardanic suspension system to give

forage.

ideal lift-out control and avoid damage to

the windrow.

14

Using professional machinery is a

must if you seek high-quality forage.

Contractors and large-scale farmers

not only look for large area outputs

without losses but also for a high qua-

lity of work, which is a critical factor in

the profit equation. The KRONE rotary

rake models Swadro 700, 800/26 and

900 feature a high number of clever

details that cater for exactly these

requirements - cardanic rotor attach-

ment, tridem axles, four reinforced

10.5 mm (0.4") diameter double tines

on each arm and cranks adjusting the

rotors to accurate work depths.

With the KRONE Swadro 700, 800/26, and 900 twin rotor rakes one can rest assured of a

smooth running of the basic foraging process.

Cardanic suspension as standard! The

Contaminated forage is unacceptable: Cardanic suspension is perfect for the production of

plate with an elongated hole allowing a free

high quality forage. The cardanic suspension means that the rotors optimally follow all

pendulum in direction of travel. From this

ground contours, even lengthwise in the driving direction and this ensures that the

point, the tridem axles guide the cardanic

predetermined working height is better maintained especially when working in uneven

linked rotors.

ground. This will pay for itself in a very short time. The tines follow the ground contours,

operate cleanly and endure less stress. The KRONE Swadros leave nothing behind on the

ground, not even in hilly or undulating terrain.

15

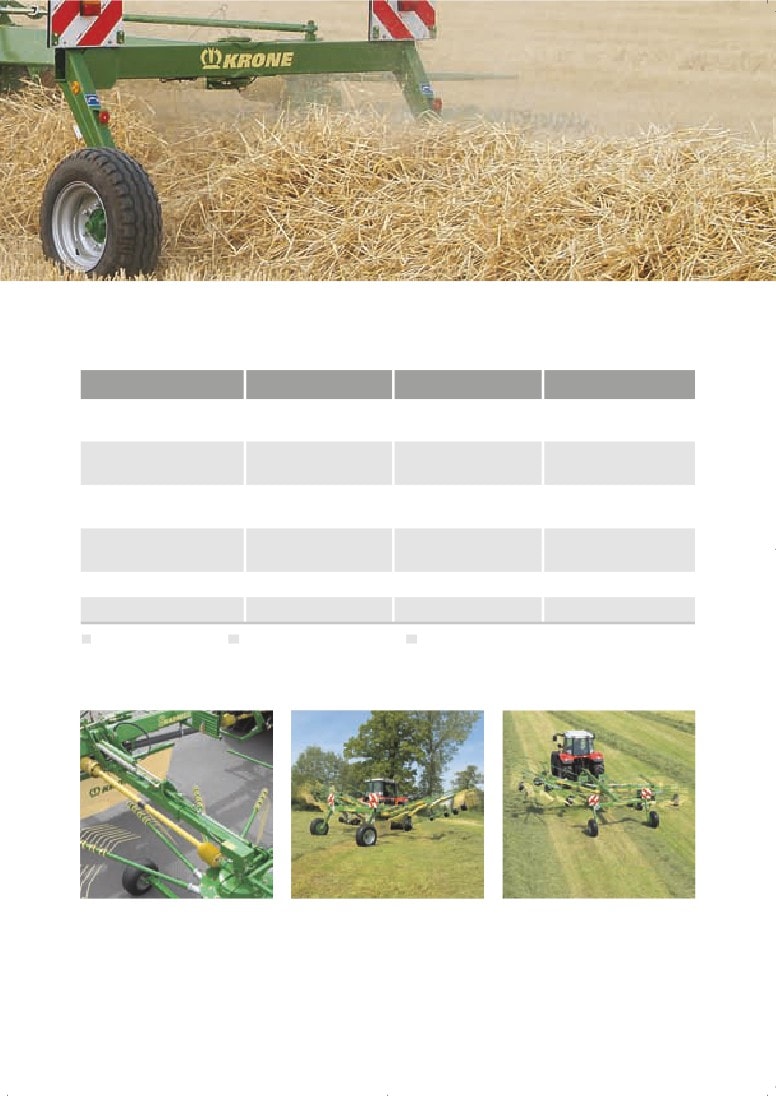

At a glance

Swadro 700

Swadro 800/26

Swadro 900

Mechanical work

+

+

+

depth control

Mechanical work

–

+

+

width control

Hydraulic work

option

option

–

width control

Separate rotor

–

+

+

lift/lower feature

Rigid tine arms

(+)

(+)

-

Folding tine arms

(+)

(+)

+

+ Base specification

(+) Required accessory

- not available

Optimized depth control - all Swadro 700,

These will tackle any job: Over-dimensio-

Straightforward system. One single-acting

800/26 and 900 rotors have cranks that

ned, single-acting hydraulic cylinders fold

spool will do to operate a Swadro 700,

allow setting their depth variably and

the rotors into the headland or transport

800/26 and 900. The Swadro 800/26 and

conveniently. Accurate depth control is

position. Coil springs are used on Swadro

900 models have a valve that is operated

essential to achieve clean rakes without

800/26 and 900 to reduce the ground

from this handle to select one or both

losses.

pressure on the gauge wheels.

rotors.

16

At 40 km/h (25 mph) you get there -

saving time and money. The transport

running gears on the KRONE twin

rotor rakes are approved to 40 km/hr

(25 mph), a specification that pays off

quickly in variable weather when you

need to change fields quickly. Folding

tine arms are available for the center-

delivery models Swadro 700, 800/26,

900 and their respective ‘Plus’ versi-

ons, enabling even faster changes.

The wide track of the running gear and the large 10.0/75-15.3 8PR tires are well thought

through with a maximum speed of 40 km/h (25 mph) in mind and provide the ideal safety

at fast speeds.

Flexible work and windrow widths. Work

Rigid arms. All rotors on the Swadro 700

Wide in the field and low on the road -

width on Swadro 800/26 and 900 models is

und 800/26 center-delivery models are also

folding tine arms are always a safe bet in

adjusted mechanically and the rotors move

available with rigid tine arms - an intriguing

areas where road travel involves passing

in / out as you operate a mechanical crank. A

option, if machine height is not an issue.

under low bridges and gateways. The arms

hydraulic work width control system is

fold quickly and easily.

available as an option.

17

Swadro 700 Plus, 800/26 Plus, 900 Plus

Ultimate level of comfort

‘Plus’ refers to one extra feature - high-level operator comfort -

Electric work depth

that is available on the center-delivery models Swadro 700 Plus,

control

800/26 Plus and 900 Plus. Providing ease of operation, these

Convenient operation from

models tick every box, everything falling into place and bringing

the electric control box

fun to field work.

Manual work width control on

Swadro 700 Plus

Hydraulic work width control

on Swadro 700 Plus,

800/26 Plus, 900 Plus

Separate rotor lift/lower feature

Cab based control - electric servomotors

Convenient - the electric control box on

Manual - Swadro 700 Plus uses a crank

control machine depth on the go, giving

Swadro 700 Plus, 800/26 Plus and 900

on its telescopic arms to adjust the working

you a superior command of the machine

Plus serves two purposes: It controls the

width. The system allows you to select the

and clean, loss-free rakes.

depth via electric motors and it preselects

desired working width and set the ideal

the left or right rotor for separate lift-out.

windrow widths for the following harvester.

18

At a glance

Swadro 700 Plus

Swadro 800/26 Plus

Swadro 900 Plus

Mechanical work

+

+

+

depth control

Mechanical work

+

-

-

width control

Hydraulic work

–

+

+

width control

Separate rotor

+

+

+

lift/lower feature

Rigid tine arms

(+)

(+)

-

Folding tine arms

(+)

(+)

+

+ Base specification

(+) Required accessory

- not available

Variable widths - Swadro 800/26 Plus and

On the headland, the operator quickly

Using only one rotor? No problem! It’s easy

900 Plus feature double-acting rams that

raises the rotors from the tractor seat. The

for Swadro. After all, this is often necessary

adjust work and windrow widths infinitely

rotors lift out high, giving plenty of ground

in low yielding crops, awkward fields and

variably and form windrows of ideal sizes

clearance to travel over massive windrows.

when raking along boundaries.

for the following harvester, boosting

harvester efficiency and cutting the overall

costs of the harvest chain.

19

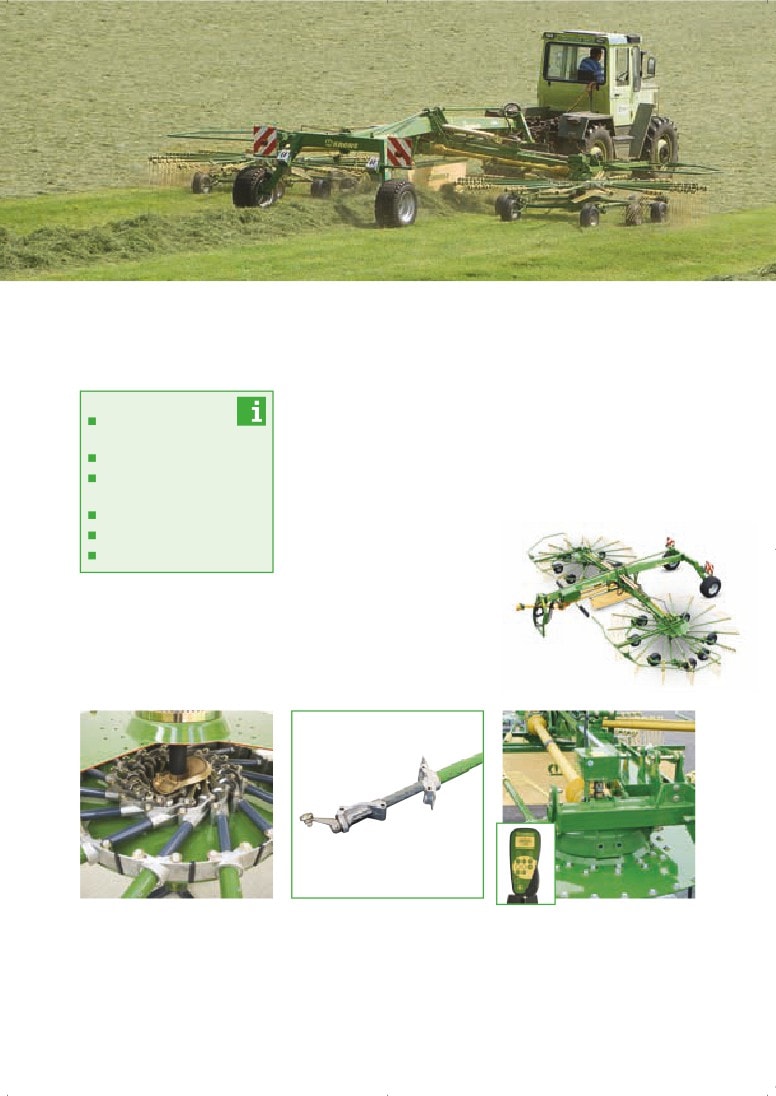

Swadro 1000

The center delivery rake with 10 m (32'10") working width

Swadro 1000 is the KRONE centre delivery rake for high-output

Variable 8.80 m - 10.00 m

and high-acreage operations. Boasting two rotors with 15 tine

(28'11"- 32'10") working widths

arms each, it rakes up to 10 hectares (25 acres) per hour. The

15 tine arms per rotor

variable 8.80 m -10.00 m (28'11"- 32'10") working width adjusts

8 castering wheels on wide

hydraulically via telescoping arms. The maintenance-free

bogies

rotors with cardan suspension and the ground hugging

Electric height control

Cardan rotor suspension

bogies with eight castering wheels

Large transport wheels

combine with a superb operational

comfort to make this center delivery

rake a flexible and high-output

machine.

High output, superior comfort and ultimate

Straightforward and simple: The operator

Height control on the move: Operators

stability - thanks to the maintenance-free

removes just four bolts and then pulls the

adjust the work height fast, steplessly and

rotors, each equipped with 15 tine arms,

tine arm from the rotor together with its

accurately from the control unit and via

the Dura-Max cam track, large guide rollers

bearings and guide roller. To replace the

electric motors, a convenient system that

in permanently lubricated bearings and

outer arm end, he simply removes two

offers ultimate flexibility in varying conditi-

widely spaced deep groove ball bearings in

hollow pins.

ons.

the Aluminium tine holder housings.

20

Swadro is KRONE’s response to

market demands for a center delivery

rake with two rotors and wide working

widths. Thanks to their special build

and straightforward design, the rotors

offer easy operation and high work

rates as they rake the crop to uniform

windrows. Boasting 15 tine arms on

each rotor and 4 double tines on each

arm, Swadro 1000 achieves highest

area outputs and perfect windrows

that maximize the efficiency of the

following harvester. Slightly tilted to

the side, it allows precise adjustment

for cleanest work. Separate rotor

lift/lower control is standard.

No crop loss: The tandem-axle bogies on

A serious machine: The trapezoidal main

Excellent tracking: The machine features

Swadro 1000 run on eight wheels for

frame is strong and durable. The tine arms

forced steering for superior tracking around

optimum ground hugging and cleanest

fold up to a transport height of less than

bends. The system consists of a tie rod,

rakes. The freely swivelling wheels provide

4 metres (13'1") and the transport chassis is

which is attached to the two-point head-

positive tracking even in the tightest bends.

approved for 40 km/hr (25 mph) for swift

stock and safely steers the wide-tracking

travel from one field to the next.

chassis on large 15.0/55-17/10 PR tires

around the tightest bends.

21

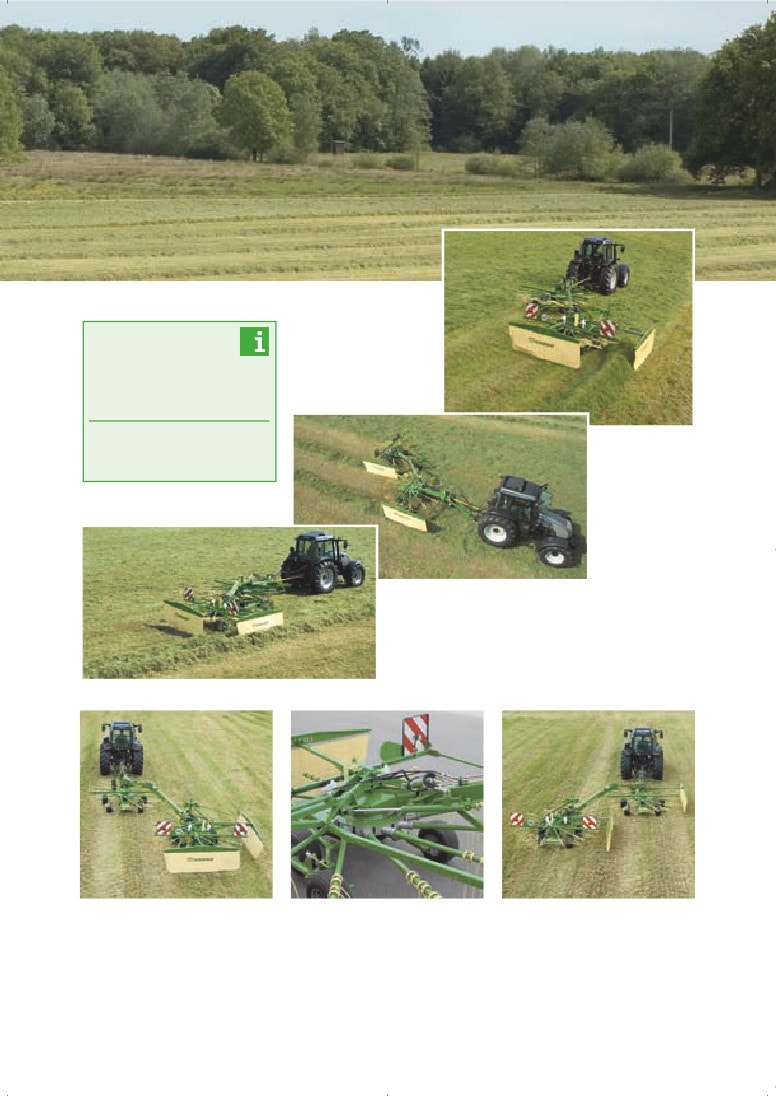

SWADRO 710/26 T

The variable Side Delivery Rakes

The KRONE 710/26 T twin-rotor side delivery rake with 13 tine

Single and double

arms not only offers excellent value for money but excellent

windrows

quality of work. Swadro 710/26 T forms single and double

Rakes to the right

windrows as well as two narrow windrows. Naturally it offers a

Variable working width

hydraulic system that adjusts the main frame to set the work

Cardanic suspension of rotors

width and thus windrow width.

Hydraulic swath curtain

adjustment

13 tine arms per rotor for

Swadro 710/26 T

For a safe connection to the pick-up hitch

With tandem axle: a broad layout with 18"

Adjusting rotor tilt: clean forage movement

or to the tractor’s trailer eye: the drawbar

tires for optimum contour following. For the

without loss must be ensured even in the

can be adjusted in height with the hitch

best possible slope stability, the front tires

heaviest of forage. The transverse slope of

being controlled via a parallelogram

are each positioned in the farthest outer

the rotor can easily be adjusted via a

linkage. The hydraulic cylinder on the hitch

position. Adjustment of the working height

spindle so that each rotor works cleanly

keeps the front rotor level during mounting

is carried out via adjustable supports that

because as the crop is transferred in the

and lifting.

are positioned with pins up a series of

direction of the swath curtain the tines have

holes.

to move more mass.

22

One 6.20 m (20'4") windrow

Two 3.40 m (11'2") windrows

A double windrow of 12.40 m (40'8")

Three functions -

Single raking

Versatile application

Twin raking

Double raking

In position for single windrowing towards

Rear rotor over to the left - rear rotor over

Over to the left and in position for twin

the right: ideal for harvesting machinery

to the right: this is done quickly and easily

windrowing: ideal for harvesting machinery

with large intake capacity and in light

with the hydraulic pivoting cylinder from the

with a low intake capacity, for voluminous

yielding crops.

tractor seat. The working width during

forage with a large mass, or for overnight

single windrowing can also be varied via

raking.

this cylinder.

23

Approved for 40 km/h (25 mph): a quick transfer and therefore low transport times is the essential criteria that increases machinery

work-rates. The wide tracked tandem axles with 18" tires provide the ideal travelling behavior at high driving speeds.

Ingenious solution: A cardanic linkage of the

The cardanic rotor suspension: this is raking technology at its finest. The cardanic

front rotor via a float position on the

suspension of the rotors ensures that the rotors always optimally follow the ground

hydraulic cylinder integrated in the drawbar

conditions, both side to side and front to back. The KRONE Swadros pick up all the crop in

and for the rear rotor via an elongated hole

a clean and tidy manner every time, whether in hilly or rolling terrain leaving nothing behind.

on the rotor suspension. The impressive

result: a large pendulum travel for the best

rotor following.

24

Reasons for choosing Swadro 710 T

with 26 tine arms: It is versatile. The

working width is variable for single

windrowing. Furthermore, two indivi-

dual, small windrows may be left

during one operation, which is ideal

for tidying up at night, or for following

harvesting machinery with a low out-

put capacity. Experts report that the

710 T makes possible, extremely

accurate front to back raking. Also

lauded are the compact transport

dimensions, the easy assembly and

disassembly, but also the lack of any

need to convert from work to the

transport position.

Perfect - raking to the right: since the operating controls are also grouped on the right

side of the tractor cab, these rakes provide the highest degree of driver comfort.

Front support wheels for perfect rotor

It holds up: the main frame with its box-

Comfortable: the hydraulic swath curtain

guidance in combination with the cardanic

section profile is robustly designed to

adjustment for the rear rotor. The adjust-

linkage: they are trailing, adjustable in

withstand huge stresses. This provides a

ment for differing windrow widths is done

height and additionally, depending on the

safety margin when driving at high speeds

from the tractor seat. For road transport,

amount of forage, can be moved sideways

on poor quality roads and while working

the curtain is retracted hydraulically.

if necessary.

under difficult conditions.

25

Swadro 807, Swadro 810

The twin rotor Side Delivery Rakes

The models Swadro 807 and 809 are engineered to rake the crop into

Swadro 810: single

one massive windrow on either side of the tractor. The Swadro 810

and twin windrowing

additionally provides the additional opportunity of laying two small

Cardanic rotor linkage

windrows in one pass. If the two large single windrows are laid side

Wide gauge running gear

by side from two passes to and fro, a total working width of up to

with steered rear axle

The front and rear rotors

14,00 m (45'11") can be acheived

are sequence controlled

depending on the windrow

size. In this manner,

enough forage can be

combined together to

maximize the performance

of any subsequent harvesting

operation to their fullest, even

in third and fourth cuts.

Variably adjusting the working height: As

The electronic control box with electrical

On-the-move working height adjustment:

standard equipment, a spindle quickly and

actuators for the adjustment of the working

the Swadro 810, when equipped with the

comfortably adjusts the working height of

height is available as an option for the

optional actuators makes the adjustment

each rotor thus ensuring the best raking

Swadro 810. The box fulfils two functions:

of the working height sensitive and precise.

effect under any condition.

the in-cab adjustment of the working height

The system is weatherproof and can be

and the pre-selection of the individual left

operated while travelling.

or right hand rotor lift.

26

Swadro 807 forms windrows from 6.20

metres (20'4"), Swadro 809 and 810

from 6.80 metres (22'4"), placing them

to side. The cardanic rotors complete

with tridem axle follow any ground

contour. The result: the cleanest raking

quality without loss.

The twin windrowing of two times 3.70 m

(12'2") with the Swadro 810 for: ideal for

following machinery with a low harvesting

capacity, or for bringing grass together at

night.

From a single to a twin windrow: no

Fully equipped: two swath curtains on the

Always the right size: the swath curtain can

problem for the Swadro 810. If necessary,

Swadro 810. Single windrowing is done

be telescopically adjusted for width. For

the inner rotor can be telescoped out from

with the outer one, twin windrowing is done

height this is done quickly and easily via

the tractor seat so that sufficient room is

utilizing both. If the inner swath curtain is

spacers. Multiple adjustment possibilities

provided for the second windrow to be laid.

not needed it can simply be folded up out

guarantee a perfect windrow shape under

of the way.

all circumstances.

27

Down the road at 40 km/h (25 mph), compact and safe: when on public roads and driving underneath low bridges and underpasses, utility

lines and masts the upper, outer tine arms can be folded in.

Agile through and through: the Swadro 807,

Optimally equipped: the large 10.0/75-15.3

They do deliver: over-dimensioned, single-

809 and 810 rake up everything due to their

8 PR tires and track-following linkage

acting hydraulic cylinders lift the rotor

high maneuverability, even in restricted

ensure absolutely smooth and stable

comfortably into the headland or transport

areas. With a wide wheel track on the

travelling - an advantage when working on

position.

running gear and a steering axle, they can

slopes or at high driving speeds.

master any corner.

28

The Swadro 807, 809 and 810 side

delivery rakes have been tested and

proven for the use with forage

harvesters. Night raking is also

possible with the Swadro 810 dual-

function rake. Thanks to their rear axle

steering, they are highly flexible, have

excellent tracking behavior and can

master any twist and turn. The well-

dimensioned wide tracked running

gear ensures complete stability on

slopes. These rakes can be easily

maneuvered, running absolutely

smoothly on the road, even at 40 km/h

(25 mph). For clean work at the head-

land these rakes, like all tandem axle

Depending on the desired windrow width, the working width when driving to and fro is up

Swadro models have, of course, also

to 15.00 m (49'3"). This results in a large enough windrow to satisfy even the most high

been equipped with the KRONE Jet

capacity of harvesters, even in the 3rd and 4th cut.

Effect.

Ground clearance galore: The placement of

Rotors connected in series: during lifting

Manufactured for high demands: the box-

the main rotor drives next to the support

and lowering, the front rotor is always

section frames of the Swadro 807, 809 and

frame enables a quicker and higher lifting of

placed into headland or working position

810 slope to be higher in the center. In this

the double tines above the ground. This

first followed by the rear. The length of time

way there is even more ground clearance

provides more clearance when driving over

taken to drop during the lowering operation

when driving over already raked windrows.

already formed windrows.

is adjustable.

29

Swadro 907

Raking 8 metres (26'3") of crop into one windrow

Swadro 907 is the KRONE twin-rotor side delivery rake with

8.00 m (26'3") work

8.00 m (26'3") work width. Running on a wide-tracking axle

width for highest work rates

and boasting 15 tine arms and 6 wheels on each rotor, this

15 tine arms per rotor

rake delivers cleanest rakes and highest workrates.

Wide bogies with 6 wheels

each

Maintenance-free rotors, the Dura-Max cam track,

Cardan rotor suspension

large guide rollers in permanently lubricated

system

bearings and widely spaced deep

Hydraulic crop deflector

groove ball bearings in Aluminium

Overrunning clutch protected

tine holder housings combine to

rotor drives

give an outstanding operator

comfort, highest workrates

and ultimate durability.

Perfect, also in heavy crops: Each of the

Direct and frictional: All gearboxes and

Adjustable coil springs for rotor sus-

large and sealed rotors runs on six

shafts mount outside the beams for easy

pension: They shift much of the jib and

castering wheels. An optional electric depth

access. The rotors are protected by star

rotor weight to the main frame to ensure

control and pin/hole tilt setting system

ratchets and the drivelines by standard

positive tracking on the slope as well as

ensure cleanest rakes and highest

overrunning clutches.

light and soft running.

productivity.

30

The KRONE Swadro 907 is a high-end

side delivery rake. Boasting an area

output of 8 ha/h (20 acres/h) and

16.00 m (52'6") work widths, this

machine gives you the edge in

foraging. The leading rotor operates

at a higher circumferential speed than

the rear unit to the end of forming the

most uniform and fluffy windrows. The

job gives the lifted rotors a high

ground clearance, an important detail

when running on raked crop. The rear

rotor lifts out with delay to the leading

rotor to provide a uniform windrow at

the end of a pass. This model features

cardan suspension for the rotors, too.

The special KRONE Jet Effect

translates into clean forage and an

undamaged headland

From the tractor seat: The left rotor features

Low transport height for safe travelling on

Excellent tracking: Thanks to double-pivot

a hydraulic crop deflector setting system,

public roads: The outer tine arms on

steering, Swadro

907 gives positive

which moves the deflector into a low trans-

Swadro 907 fold up fast and easily. With

tracking behind the tractor in any bend. The

port position and adjusts it to different

tines in their fold-up position, the rake

robust and wide-tracking chassis runs on

crops and yields.

passes easily under bridges and passage-

large

15.0/55-17/10 PR tires for quiet

ways.

running and is approved for 40 km/h (25

mph) road speeds.

31

Swadro 1010

The Side Delivery Rake with three rotors

A double windrow of nearly 20.00 metres (65'7") - these are

High output with 9.70 m

ideal windrow conditions for a high-performance forage

(31'10") working width

harvester. The KRONE Swadro 1010 three-rotor side

Working height adjustment

windrow rake takes this task on completely and convinces

via electric actuators

with a potential work-rate of up to 10 hectares

Transport running gear with

high driving comfort

(24 acres) per hour making the crop

Cardanic rotor suspension for

chain even more efficient. Thanks

the best ground alignment

to the wide tracked running

KRONE-Jet-Effekt

gear with steering axle,

this large-scale rake is

extremely agile and is very

easy to maneuver.

Contaminated forage? No thank you!

Guidance at its best: the combination of

A rear axle that steers: for an optimal

Changing application conditions often

tridem running gear and cardanic rotor

tracking behaviour and excellent agility.

require immediate adjustment of the

suspension ensure clean raking, also on

The over-sized running gear with large

working height. This can be done while

uneven ground. The following front wheels,

15.0/55-17/10

10 PR implement tires

driving via the weatherproof electric actua-

connected via a track rod, follow round

stands for safety and is gentle on the turf.

tors, which can be adjusted by the driver

even the tightest of curves.

via an electronic control box.

32

With rotors that are perfectly aligned with each other: in order to create a clean side windrow, on a working width

of 9.70 m (31'10"), everything must be right. For this reason the Swadro 1010 has different rotor diameters with

different speeds. The front rotor is equipped with 10, yet the center and rear rotors are each equipped with 13 tine

arms. The front and center rotors have higher peripheral speeds and this results in a better flow of forage. The slowly

rotating rear rotor is equipped with 5 double tines per arm because it must move more volume of grass and is

responsible for the shape of the windrow.

Reaching the destination at 40 km/h (25

In prefect alignment with each other with a matched working width of 9.70 m (31'10"): no

mph), and with a transport width of below

forage is run into the ground as the tractor pulling the Swadro 1010 runs nicely in the wheel

3.00 m (9'10"): the three rotors can quickly

tracks of the KRONE BiG M high-performance mower-conditioner.

be brought into transport position. Since

the rotor diameter of the center rotor is

below 3.00 m (9'10"), the tine arms on the

center rotor do not need to be folded in.

33

Swadro 1400

Four-fold power

The four-rotor center delivery rakes from KRONE are productive

Variable working width

workhorses. With the Swadro 1400 and an adjustable working

up to 13.50 m (44'4")

width of between 11.00 and 13.50 m (36'1" and 44'4"), one can

Alpha, Gamma and CCI -

easily handle more than 13 hectares (32 acres) per hour with

three options for high

operator comfort

just one tractor. This giant

Electric depth control from

performance enables the

the tractor seat

replacement of two twin

Folding tine arms bring

rotor rakes with merely

transport height down to

less than 4.00 m (13'2")

one Swadro 1400.

Separate rotor lift/lower feature

Robust and well thought out: the lower link

Optional specification: The drawbar on

High load-bearing: in conditions of higher

mounted headstock has pendulum

Swadro 1400 features a ball hitch and

than usual operational stresses are not

suspension adjusting ideally to all lateral

hydraulic height adjustment. Tractor attach-

always ideal. For this reason the Swadro

tractor movements. If the tractor’s lower

ment and removal is easy. No link arms

1400 has a very robust frame, thereby

links arms are lifted inadvertently the PTO

required. No jolting. All operation is safe

completely meeting the high requirements

shaft cannot be damaged.

and absolutely comfortable.

found in practice.

34

The even, well formed center windrow

left by the Swadro 1400 ensures an

even better efficiency of any following

harvesting machinery with contractors

talking about an increase in intake

capacity of the forage harvesters by

more than 20 %. Swadro 1400 boasts

plenty of innovations, such as carda-

nic rotor attachment, the KRONE Jet

effect, the extra hard Dura-Max cam

track with 3-year warranty and electric

servomotors for depth control.

The windrow is magnificent: with the Swadro 1400, the peripheral speed of the front rotor is

higher than that of the rear rotor and this optimal matching of two rotor speeds is a KRONE

innovation, the result of which is a perfectly even, box-shaped, loosely made windrow.

For professional use: with 13 tine arms per

Spring compensation: tension springs dis-

Clearance galore: the linkage of the sus-

rotor, four double tines per arm, ground-

place a large part of the weight of the front

pension arms coupled with the horizontal

covering tridem axles and the cardanic

telescopic arms and rotors back onto the

position of the main frame enable additio-

rotor linkage ensure an optimal ground

main frame. This prevents the rotors from

nal lifting power and thanks to a sequen-

alignment in all directions.

sinking in on moist ground and ensures

ced actuation the front rotors are always

that the rake follows in the tractor tracks in

lifted or lowered first.

hillside situations.

35

Wide in the field and narrow on the

road - enjoy the sense of safety that

comes from the air brake system on

the 40 km/h (25 mph), wide-base run-

ning gear, from the large tires and a

less than 3 m (9'10") transport width.

Folding tine arms and a chassis that

inclines toward the tractor combine to

bring Swadro 1400’s transport height

down to less than 4.00 m (13'2"),

helping you comply with regulations

and providing safe passage under

bridges, gateways, overhead lines and

tree branches.

Premium-level electronic control

- the

The Alpha terminal for Swadro 1400 is used

The Gamma terminal with a backlit digital

ISOBUS compatible board computer

to control work depth and width as well as

display screen provides an excellent over-

allows operators to use their preferred

the width of the windrow. Simply press a

view of all machine functions and allows

KRONE operator terminal - Alpha (only for

button to raise and lower one rotor or both

Swadro 1400 Plus operators to have all

Swadro 1400), Gamma or CCI - or an

rotors sequentially. Swadro 1400 is compa-

rotors automatically adjusted to a program-

ISOBUS compatible tractor terminal.

tible with the tractor’s load sensing system.

med height.

36

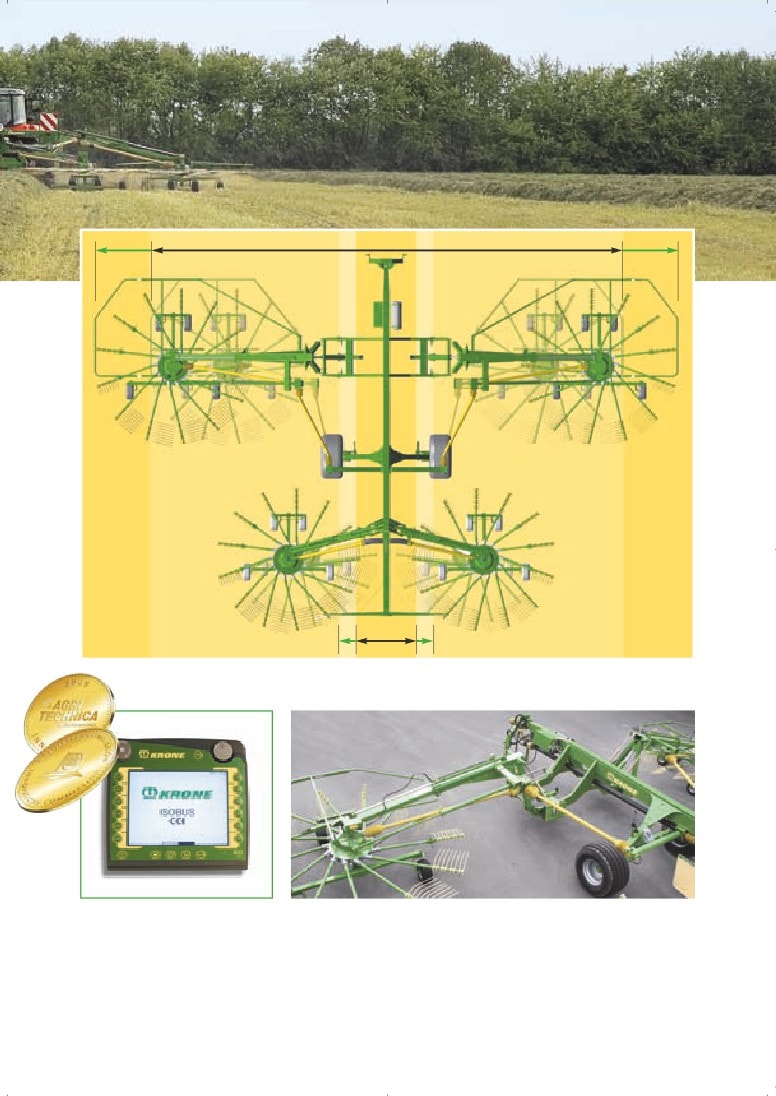

Working width: 11,00 to 13,50 m (36'1" to 44'4")

Windrow width:

1.40 to 2.20 m

(4'7"-7'3")

Terminal CCI 100: CCI-ISOBUS is one

11 m - 13.5 m (36'1" to 44'4") work widths: The system gives you the flexibility you need

control box for all. This terminal comprises

to operate in varying conditions and to different requirements. You can vary windrow

not only all Alpha and Gamma functions

widths from about 1.40 m to 2.20 m (4'7"- 7'3") by adjusting the rear rotors. The working

but provides universal control on the

width of the front and rear rotors is set hydraulically via telescoping arms. As these also

ISOBUS machines from a large number of

reposition the right-angle gearboxes that drive the front rotors via driveshafts, the system

manufacturers.

ensures optimum overlapping of the telescoping arms.

37

Swadro 1400 Plus

Ultimate performance

The plus about Swadro 1400 Plus is its superior operator

Transport running gear

comfort and top performance in really tough conditions.

lowers hydraulically to a

The comprehensive base specification level includes the

transport height of less than

hydraulically lowering running gear, electric Comfort height

4.00 m (13'2")

No folding tine arms

control and extra strong driveshafts, ticking every box.

Automatic depth control after

setting the depth on the first

rotor

Heavy-duty driveline for

constant operation in

demanding applications

Superior operator comfort

from the Gamma or CCI 100

operator terminals

The swath deflector in the middle is an

Electric Comfort rotor height control. Select

Powerful driveline - the gearboxes mount

option. It helps forming perfect windrows,

from the cab the depth for the first rotor.

far out on the wings for driveshafts to run

also when raking with one rotor raised out

After that, the servomotors set the remai-

smoothly. Swadro

1400 Plus features

of work. The deflector curtain folds auto-

ning rotors automatically to identical

heavy-duty driveshafts and the rotors are

matically into transport position to provide

depths.

star ratchet protected.

good ground clearance.

38

Machine viability is vital for contracting

businesses. Viability refers to high area

outputs, quick conversion, low main-

tenance, fast road transports, long

machine lifetime cycles and of course

high operator comfort. The four-rotor

center-delivery rake Swadro 1400 Plus

was designed for contractors. This

machine is fully controlled from the

tractor seat to get you to the next field

quickly and deliver!

Move the rotors in transport position from

Lowering the transport height to less the

Choose between standard 500/50-17/10

the tractor seat. The hydraulic height con-

4.00 m (13'2"), the hydraulic axle quickly

PR tires and bigger 560/45-22.5 tires,

trol system lowers the axle to a less than

converses Swadro 1400 for road travel,

which have proven its worth on the

4.00 m (13'2") transport height, so that

saving time and boosting operator comfort.

transport chassis running in hilly terrain.

Swadro 1400 Plus has no requirement for

Both versions are approved for 40 km/hr

folding the tine arms. The tine arms are

(25 mph).

rigid on this model.

39

Swadro 2000

The champion among the center-delivery rakes

Swadro 2000 features 6 rotors that work at a width of 19.00 m

Variable 10 m-19 m

(62'4"). This working width gives you the potential to rake up to

(32'10"- 62'4") work widths

20 ha (49 acres) per hour. This enormous efficiency combines

Variable 1.6 m-2.8 m

with a uniform quality of work and fluffy windrows - thanks to the

(5'3"- 9'2") windrow widths

leading rotors spinning faster than the units at the rear. These

Cleanest rakes from

windrows are ideal for hungry harvesters. Swadro 2000 boasts

6 maintenance-free and

small 330 mm (1') rotors

plenty of innovations, such as cardanic rotor attachment for

Synchronized width control

excellent adaptation to ground contours and especially hardened

via sliding carriages

Dura-Max cam tracks with 3-year warranty. Attaching / removing

Height control via electric

the tine arms is quick and easy. The arms are fully specified with

servomotors

bearings and guide rollers. Simply remove two or four bolts and

pull out the arm. It's as easy as that.

A unique KRONE design - the four leading

Perfect control. The tridem axles account

Convenient - electric motors adjust the

rotors feature 13 tine arms that spin at

for clean forage, because the wheels run

working depth, either on each rotor

higher speeds than the following rotors,

closely behind the inner tines and provide

separately or automatically one after the

each boasting 15 tine arms. It is this

optimum ground following. The castering

other. The function is carried out from the

difference in rotor speed

(3,300 mm

wheels follow every bend and protect the

tractor seat for quick adaptation to current

(10'10") rotor diameters) that leads to

turf.

conditions.

cleanest rakes and fluffy windrows.

40

Powerful driveline, low input requirement,

Flexible work widths: The current working

Hydraulic windrow width control allows

tidy design - the rotors are driven by the

width is varied hydraulically by the

operators to telescope the two rear rotors

central gearbox, the position of which

swinging arms to match windrow widths to

in or out to vary the distance between them

reduces the number and length of the

the capacity of the following harvester. The

and match windrow widths to the capacity

driveshafts required. Each rotor features its

action of two swinging arms is

of the following harvester and boost

own separate overload protection.

synchronized by the sliding carriage.

efficiency and profitability.

41

Gigantic in work - compact in transport

Working at widths of up to 19.00 m (62'4") and folding into a

Synchronized

narrow transport width of 3.00 m (9'10"), Swadro 2000 is an

changeover from the cab

impressive performer both in the field and on the road.

No removal of tine arms

Featuring six rotors, this machine is a new symbol of efficiency.

Less than 3 m (9'10")

Swadro 2000 caters for a wide range of applications including

transport width

large-scale farms and contract work, which involves frequent

Less than 4 m (13'2")

travelling between sites and therefore

transport height

frequent changeovers. For that

reason, Swadro 2000 features

tine arms that do not

require folding.

In addition, it

provides for

in-cab control of

the entire changeover process.

Perfect support: The swinging arms run on

Anything is possible. Swadro 2000 offers a

In 'sync' - the swinging arms are linked to

unsteered 15.0/55-17/10 wheels, which

range of optional functions: lift/lower only

the main beam via hydraulic carriages. The

mount on the ends of the arms and swing

one rotor or one after the other or all rotors

system not only adjusts the working width

up for transport. The arms swing in to rest

at the same time. Sequence control

but also swings the rotors in transport and

on the main beam and lock into position.

functions make headland turns a piece of

work position.

cake. All rotors swing up 90° into transport

position.

42

Easy going

One-touch control changes into

transport position:

Swadro 2000 also stands out for easy

handling and functionality during

changeovers, where automatic

sequence control and the high

operator comfort reduce operator

fatigue and lead to higher daily

outputs.

How you do it:

First, lift the rotors to headland

position. Then retract the two rotor

arms at the rear. At the same time, the

two leading beams with the front and

central rotors swing in as well. All

action is synchronized by the sliding

carriage on the main beam, an ideal

system for slope operation. Extra

guidance and stability comes from the

unsteered wheels on the ends of the

arms. The wheels swing up for the

swinging arms to rest on them along

the side of the main beam. As a last

step, the rotors fold into vertical

position and the machine is ready for

safe and compact road travel.

43

Swadro 2000

Technology of ultimate perfection

Swadro 2000 not only impresses by its tremendous working width

Easy steering Easy

but also by its ease of handling and great maneuverability. It is

operation Sequence control

equipped with a pivot steer axle that travels around any bend.

and Comfort height control

This agility is required for contract work in small fields. The

Separate rotor lift/lower

transport chassis is approved to 40 km/hr (25 mph) and features

Steered axle with active and

passive function

large flotation tires to minimize

Uniform windrow presentation

ground pressure and effectively

protect the windrow.

Robust by design, Swadro 2000 hitches to

Innovative steering: The steering linkage

Maneuvering and working in awkward

the tractor's link arm. The flexible cat II/III

moves hydraulically to the side to enable

patches is made easy thanks to the

headstock compensates for any humps

steering. The hydraulic ram is activated as

hydraulic auxiliary steering system that is

and bumps while the strong stand provides

the rotors lift and lower. It extends to

integrated in the steering linkage and which

uncompromised stability. Holders are

activate steering and retracts to inactivate

allows the operator to actively steer the

provided for tidy storage of driveshaft and

steering.

transport running gear from the tractor

supply lines.

seat. This increases the steering angle even

further for even tighter turns.

44

In response to user demands, KRONE

developed its genuine double-pivot

steering axle, which offers ultimate

comfort when travelling between

fields. The axle is passive when the

machine is raking to ensure uniform

and straight windrow formation. As the

rotors lift out of work, the steering axle

is activated automatically to give the

rake best tracking in tight headland

turns and road bends. This auxiliary

steering system allows the operator to

steer the axle from the tractor seat

when passing through narrow gates or

when raking up awkward patches.

This innovative system boosts

efficiency in small fields and increases

your work rates.

Double-pivot steering on the transport

Comfort height control: The electric control

The easy-to-use control unit operates all

running gear allows for wide steering

unit has a digital display screen, where the

major functions

- work width, rotor

angles and therefore excellent tracking. It

operator sets working and windrow widths

lift/lower via customizable sequence

makes the combination very nimble and

and all rotors to a preset level.

control and operates the individual rotors.

also offers high stability on the slope.

45

Technical Data

Three-point linkage single-rotor rakes

Model

Swadro 35

Swadro 38

Swadro 42

Swadro 46

Work width

mm (inch)

3,500 (11'6")

3,800 (12'6")

4,200

4,600

Area output approx. ha/h (acres/h)

3 (7.4)

3.5-4 (8.6-9.8)

4-4.5 (9.8-11)

4.5-5 (11-12.3)

Transport width

mm (inch)

1,900 (6'3")

1,900 (6'3")

2,265 (7'5")

2,550 (8'4")

No. of tine arms

10

10

13

13

No. of double tines

30

40

52

52

Rotor diameter

mm (inch)

2,700 (8'10")

2,960 (9'9")

3,300 (10'10")

3,600 (11'10")

Tire size on bogie

16x6.50-8

16x6.50-8

16x6.50-8

16x6.50-8

Power requirement approx. kW/hp

22/31

22/31

37/50

37/50

Weight

approx. kg (lbs)

532 (1,173)

569 (1,254)

640 (1,411)

665 (1,466)

Three-point hitch

Standard

Standard

Standard

Standard

Storage length

mm (inch)

3,120 (10'3")

3,390 (11'2")

3,690 (12'1")

3,990 (13'1")

Storage height

mm (inch)

2,210 (7'3")

2,210 (7'3")

2,490 (8'2")

2,640 (8'8")

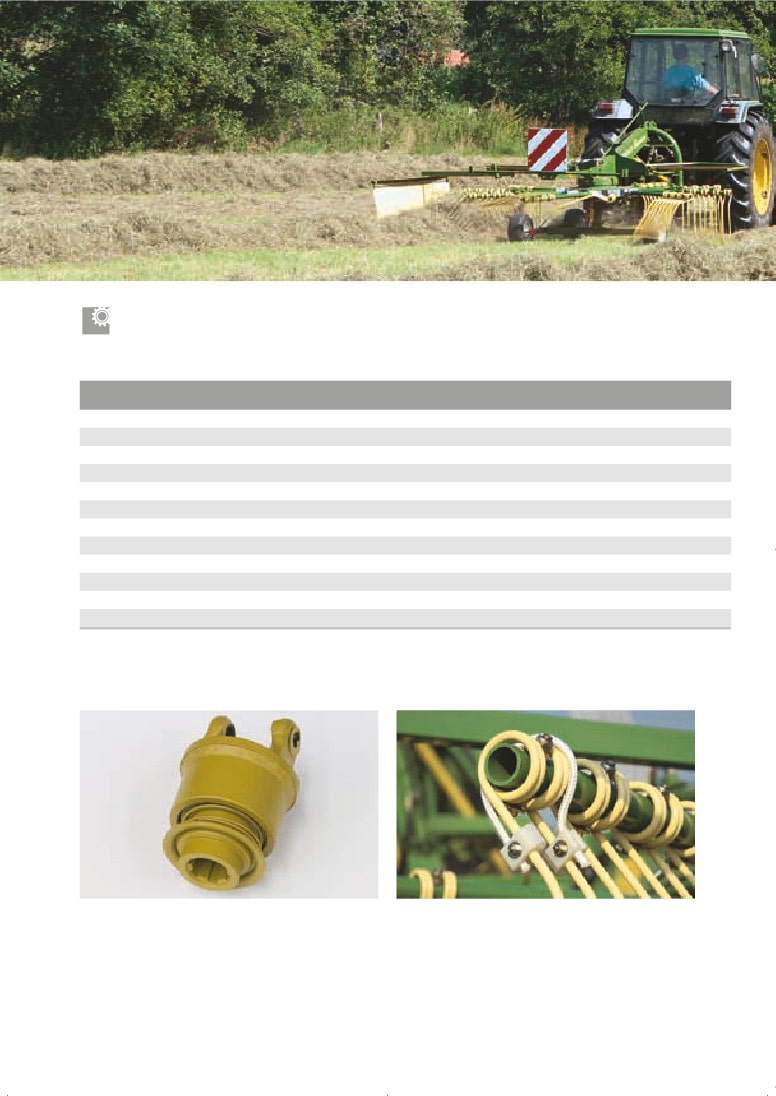

Overrunning clutch: The Swadro 35, 38, 42 and 46 models can be

An anti-tine-loss system is available for all KRONE rotor rakes. The

specified with an optional overrunning clutch for the driveshaft,

system traps the tine when it breaks, so that it is not lost in the

which is ideal on tractors with pto brake. The clutch protects

windrow, where it will cause further damage in the following harvester.

tractor and machine when shutting off the pto.

46

Trailed single-rotor rakes

Model

Swadro 38 T

Swadro 42 T

Swadro 46 T

Work width

mm (inch)

3.800 (12'6")

4.200 (13'9")

4.600 (15'1")

Area output

approx. ha/h (acres/hr)

3,5-4 (8.6-9.8)

4-4,5 (9.8-11)

4,5-5 (11-12.3)

Transport width

mm (inch)

2.995 (9'10")

3.400 (11'2")

2.550 (8'4")

No. of tine arms

10

13

13

No. of double tines

40

52

52

Rotor diameter

mm (inch)

2.960 (9'9")

3.300 (10'10")

3.600 (11'10")

Tires

18/8.5-8/6 PR

18/8.5-8/6 PR

18/8.5-8/6 PR

Power requirement

approx. kW/hp

19/25

21/31

21/31

Weight

approx. kg (lbs)

730 (1,609)

780 (1,720)

820 (1,808)

Drawbar

Standard

Standard

Standard

Storage length

mm (inch)

4.800 (15'9")

4.950 (16'3")

5.100 (16'9")

Storage height

mm (inch)

1.250 (4'1")

1.250 (4'1")

2.200 (7'3")

Swadro 38 T and 42 T are marketed in export markets only

KRONE is serious about aftersales service, because every

operator has at least once seen his harvest chain grind down to a

halt because of a downed machine - clearly an experience we all

can do without. However, when this does happen then every

minute counts. KRONE is aware of that and operates a dense net-

work of professional dealerships, which operate well-stocked

warehouses near your operation. Striving for ultimate efficiency,

we are here to help you. KRONE - hay and forage technology.

Approved quality pays off, and therefore Original parts are

less costly. Haven't you been through the experience at least

once when your local dealer claimed a part was high-quality and

then it did not work? Tests conducted by agricultural magazines

have shown that manufacturer-tested quality parts last longer and

operate more reliably. Do not compromise on quality and trust in

Original KRONE parts.

47

Technical Data

Trailed side-delivery rakes

Model

Swadro 710/26 T

Swadro 807

Work width single raking

mm (inch)

6,200 (20'4")

6,200 (20'4")

double raking

2x3,400 (2x11'2")

-

No. of rotors

2

2

Area output

Approx. ha/h

5.5-6 (13.5-14.8)

6 (14.8)

Transport width

mm (inch)

2,995 (9'10")

2,990 (9'9.7")

No. of tine arms

26

23

No. of double tines

91

96

Rotor diameter

mm (inch)

2,960 (9'9")

2,960 (9'9")

Work depth control

mechanical

+

+

electric

Tire size on bogies

18/8.5x8/6

16x6.50-8

Tire size on running gear

18/8.5x8/6

10.0/75-15.3/8 PR

Power requirement

Approx. kW/hp

37/50

37/50

Weight

Approx. kg (lbs)

1,600 (3,527)

1,800 (3,968)

Two-point hitch

-

Standard

Drawbar

Standard

-

Storage length

mm (inch)

8,400 (27'7")

7,300 (23'11")

Rigid tine arms

+

(+)

Folding tine arms

-

(+)

Storage height

machine with rigid tine arms

mm (inch)

1,300 (4'3")

3,850 (12'8")

machine with folding tine arms

mm (inch)

-

3,400 (11'2")

(+) = Required accessory

+ = Base specification

- = Not available

48

Swadro 809

Swadro 810

Swadro 907

Swadro 1010

6,800 (22'4")

6,800 (22'4")

8,000 (26'3")

9,700 (31'10")

-

2x3,700 (2x12'2")

2

2

2

3

6.5-7 (16-17.3)

6.5-7.5 (16-18.5)

8-9 (19.7-22)

9-10 (22-24.7)

2,995 (9'10")

2,995 (9'10")

2,995 (9'10")

2,995 (9'10")

26

26

30

36

104

104

120

157

3,300 (10'10")

3,300 (10'10")

3,800 (12'6")

1 x 2,960 (1 x 9'9")

2 x 3,600 (2 x 11'10")

+

+

+

-

16x6.50-8

16x6.50-8

16x6.50-8

16x6.50-8

10.0/75-15.3/8 PR

10.0/75-15.3/8 PR

15/55-17/10 PR

15/55-17/10 PR

37/50

37/50

51/70

59/80

1,920 (4,233)

1,980 (4,365)

2,800 (6,173)

2,920 (6,437)

Standard

Standard

Standard

Standard

-

-

-

-

7,770 (25'3")

7,770 (25'3")

8,500 (27'11")

9,800 (32'2")

-

-

-

-

Standard

Standard

Standard

Standard

4,170 (13'8")

4,170 (13'8")

4,400 (14'5")

4,300 (14'1")

3,720 (12'3")

3,720 (12'3")

3,900 (12'10")

3,800 (12'6")

49

Technical Data

Trailed center-delivery rakes

Model

Swadro 700

Swadro 700 Plus

Swadro 800/26

Swadro 800/26 Plus

Work width

mm (inch)

6,800

6,800-7,600

6,800-7,600

6,800-7,600

(22'4")

(22'4"-24'11")

(22'4"-24'11")

(22'4"-24'11")

Manual work width control

-

Standard

Standard

-

Hydraulic work width control

-

-

-

Standard

No. of rotors

2

2

2

2

Area output

Approx ha/h (acres/h)

6.5 (16)

7 (17.3)

7.5

(18.5)

7.5

(18.5)

Transport width

mm (inch)

2,900 (9'6")

2,900 (9'6")

2,900 (9'6")

2,900 (9'6")

No. of tine arms

20

20

26

26

No. of double tines

80

80

104

104

Separate rotor lift/lower feature

-

Standard

Standard

Standard

Rotor diameter

mm (inch)

3,300

3,300

3,300

3,300

(10'10")

(10'10")

(10'10")

(10'10")

Manual work depth control

Standard

-

Standard

-

Electric work depth control

-

Standard

-

Standard

Central swath deflector

Optional

Optional

Optional

Optional

Lowering running gear

-

-

-

-

Tire size on bogies

16x6.50-8

16x6.50-8

16x6.50-8

16x6.50-8

Tire size on running gear

10.0/75-15.3/8 PR10.0/75-15.3/8 PR

10.0/75-15.3/8 PR

10.0/75-15.3/8 PR

Power requirement

Approx. kW/hp

37/50

37/50

37/50

37/50

Weight

Approx kg (lbs)

1,550 (3,417)

1,550 (3,417)

1,700 (3,748)

1,700 (3,748)

Two-point hitch

Standard

Standard

Standard

Standard

Drawbar

-

-

-

-

Storage length

mm (inch)

5,725 (18'9")

5,725 (18'9")

5,725 (18'9")

5,725 (18'9")

Folding tine arms

(+)

(+)

(+)

(+)

Rigid tine arms

(+)

(+)

(+)

(+)

Storage height at minimum work width

Machine with rigid tine arms mm (inch)

3,995 (13'1")

3,995 (13'1")

3,995 (13'1")

3,995 (13'1")

Machine with folded tine arms mm (inch)

3,570 (11'9")

3,570 (11'9")

3,570 (11'9")

3,570 (11'9")

(+) = Required accessory

+ = Base specification

- = Not available

Swadro 900

Swadro 900 Plus Swadro 1000

Swadro 1400

Swadro 1400 Plus Swadro 2000

7,700-8,800

7,700-8,800

8,800-10,000

11,000-13,500

11,000-13,500

10,000-19,000

(25'3"-28'11")

(25'3"-28'11")

(28'11"- 32'10")

(36'1"-44'4")

(36'1"-44'4")

(32'10"-62'4")

Standard

-

-

-

-

-

-

Standard

Standard

Standard

Standard

Standard

2

2

2

4

4

6

8-8.5 (19.7-21)

8-8.5 (19.7-21)

9-10 (22-24.7)

12-14 (29.6-34.5)

12-14 (29.6-34.5)

15-20 (37-49.2)

2,990 (9'9.7")

2,990 (9'9.7")

2,990 (9'9.7")

2,995 (9'10")

2,995 (9'10")

2,995 (9'10")

26

26

30

4x13

4x13

4x13/2x15

104

104

120

208

208

328

Standard

Standard

Standard

Standard

Standard

Standard

3,600

3,600

4,200

3,600/3,300

3,600/3,300

3,300

(11'10")

(11'10")

(13'9")

(11'10"/10'10")

(11'10"/10'10")

(10'10")

Standard

-

-

-

-

-

-

Standard

Standard

Standard

Standard

Standard

Optional

Optional

Standard

Optional

Optional

-

-

-

-

-

Standard

-

16x6.50-8

16x6.50-8

16x6.50-8

16x6.50-8

16x6.50-8

16x6.50-8

10.0/75-15.3/8 PR

10.0/75-15.3/8 PR

15.0/55-17/10 PR

500/50-17/10 PR

500/50-17/10 PR

600/50-22.5 PR

(560/45-22.5 PR)

(560/45-22.5 PR)

(800/45-R 26.5)

40/55

40/55

51/70

59/80

59/80

96/130

2,050 (4,519)

2,050 (4,519)

2,950 (6,504)

4,600 (10,141)

5,400 (11,905)

9,400 (20,723)

Standard

Standard

Standard

Standard

Standard

Standard

-

-

-

Option

Option

-

6,350 (20'10")

6,350 (20'10")

7,000 (23')

8,440 (27'8")

8,500 (27'11")

13,200 (43'4")

+

+

+

+

-

-

-

-

-

-

+

+

4,250 (13'11")

4,250 (13'11")

4,550 (14'11")

4,360 (14'4")

3,995 (13'1")

3,995 (13'1")

3,780 (12'5")

4,250 (13'11")

3,900 (12'10")

3,850 (12'8")

-

-

Internet

Discover the world at KRONE and browse through our website pages

to find facts and figures and also new developments plus a wide range

of services. Explore our website and find out how versatile the KRONE

world is.

News

Service

Click here to find up-to-the minute information about KRONE -

Here you find all the service information you require - from

from new product presentations to show reviews. Here you are

a point of contact at the factory to finance schemes for your

at the pulse of KRONE life.

KRONE machine as well as training schemes for staff and users.

Products

Find extensive information on our full product range. This section

Download Center

holds everything you need - from video clips to manuals.

Are you looking for a KRONE calendar for your desktop or a

smart picture for your presentation? Here, at the KRONE

download center, you will find plenty of useful material for a wide

Sales organisation

range of projects.

Here you find a distributor in Japan as well as your local KRONE

dealer who will be pleased to support you. This is where you find

Used Machinery

your KRONE partner who will be pleased to assist you.

KRONE often has a wide range of demonstration or exhibit

machinery on offer. This is a good site to find your KRONE

Jobs

machine. Then contact your local KRONE dealer to arrange the

Would you like to join our company? KRONE is often looking

details of a potential purchase.

for diligent and motivated staff to work at our farm machinery

factory as well as at our commercial trailer production plant. So,

Parts

this section is always worth a visit.

24 / 7... This service gives you the opportunity to find your

KRONE part at any time and without waiting. The KRONE

Media center

Agroparts Portal has an article number and exact description for

The KRONE ‘database’ holds thousands of documents, pictures,

every part. You can order the part instantly at your local KRONE

test reports and much more. Here you find very detailed

dealer by sending an e-mail to Agroparts.

information on KRONE products that are of special interest to

you.

KRONE shop

Are you looking for a gift or are you a collector of farm models?

Events

Then you should definitely shop around at our KRONE shop. We

Are you in for a KRONE live experience? Check out for KRONE

take your orders at any time of the day.

events and look at a machine on show or watch it during a

demonstration. After all, there is little that is more effective than

a hands-on experience.

Your KRONE dealer

Maschinenfabrik Bernard KRONE GmbH

Heinrich-Krone-Straße 10

D-48480 Spelle

Telefon: +49 (0) 5977. 935-0

Telefax: +49 (0) 5977. 935-339

info.ldm@krone.de