Always on the cutting edge.

TABLE OF CONTENTS

Introduction | 4

Side-Pull Disc Mower Conditioner | 5

RazorBar™ Cutterbar | 6

Center-Pivot Disc Mower

Conditioner | 8

Conditioning Options | 10

Service & Support | 12

Specifications | 14

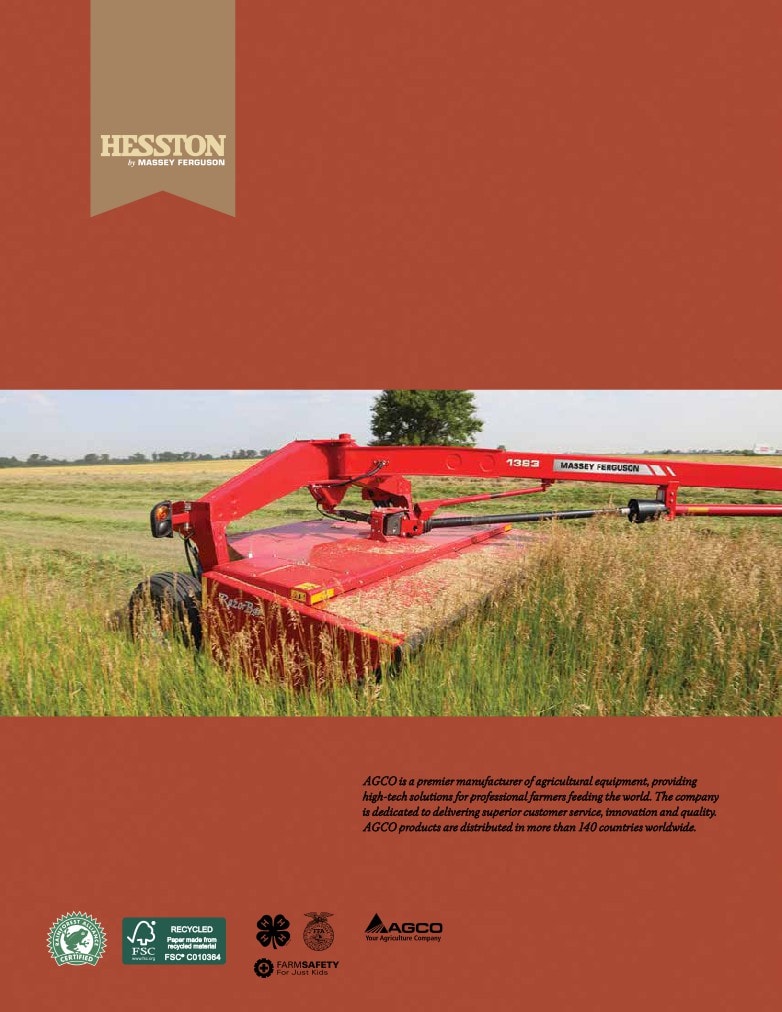

1947

The Hesston Manufacturing Company is

founded in Hesston, KS. Today it is part of

the Massey Ferguson® family.

1962

Massey Ferguson becomes the

world’s best-selling tractor bran

1974

The Hesston® 1014 mower conditioner

is introduced, the industry’s first

commercially available center-pivot

mower conditioner.

2006

Massey Ferguson and Hesston

join forces to produce the new

Hesston by Massey Ferguson

complete line of hay equipment.

2014

The Hesston 1383 & 1386 are the

first ever pull-type mowers to have

hydraulic conditioner tension.

2016

Hesston has proudly built high quality hay equipment

for 70 years. Since 1947, Hesston has lead the way with

industry-leading innovations like the first self-propelled

swather, the first large square baler, the first center pivot

mower conditioner plus many more. High quality hay

is what we do. High quality hay is what we know.

Nobody knows hay like Hesston.

Hesston.com | 3

The experience leader.

Ah, the smell of fresh-cut hay. Whether you cut your

That’s why Hesston by Massey Ferguson goes to such

own crop twice a year or custom harvest 500 acres six

great lengths to ensure that every Hesston 1300 Series

times per season, there’s always something comforting

disc mower conditioner features smooth cutting, maximum

about the sweet aroma of newly cut forage. Unfortunately,

efficiency and unmatched reliability. It’s also the reason

the tranquility associated with the sights and smells of

we offer five different models of disc-type sizes. We realize

nature can be shattered by a machine that strips the crop

that every farm is different and every farmer and rancher

or plugs on the job.

has different needs.

The Hesston 1359:

Redefining economy.

When your needs call for a versatile yet cost-efficient

disc mower conditioner, you can’t do better than the

Hesston 1359. Its seven rotary discs cut a 9-foot, 3-inch

swath through grass hay, pasture or alfalfa with equal

ease. Yet, the rugged side-pull hitch easily pivots for

narrow transport. Add our proven hay conditioner

Standard knives feature a

options to match your crop conditions and you have the

12-degree pitch. For tough

perfect machine for any small- to mid-size operation.

conditions like down crop,

18-degree knives are also

available for more lift and

a cleaner cut.

A hydraulic power-out feature on the

Hesston 1359 automatically opens the rolls

to expel slugs when the header is raised.

Each cutterbar module is driven by

a segmented, reversible hex drive shaft

for quick disassembly and reduced

operating costs. The hex drive shaft is

also designed to absorb the shock of

hitting an obstruction, reducing the

risk of damage.

Hesston.com | 5

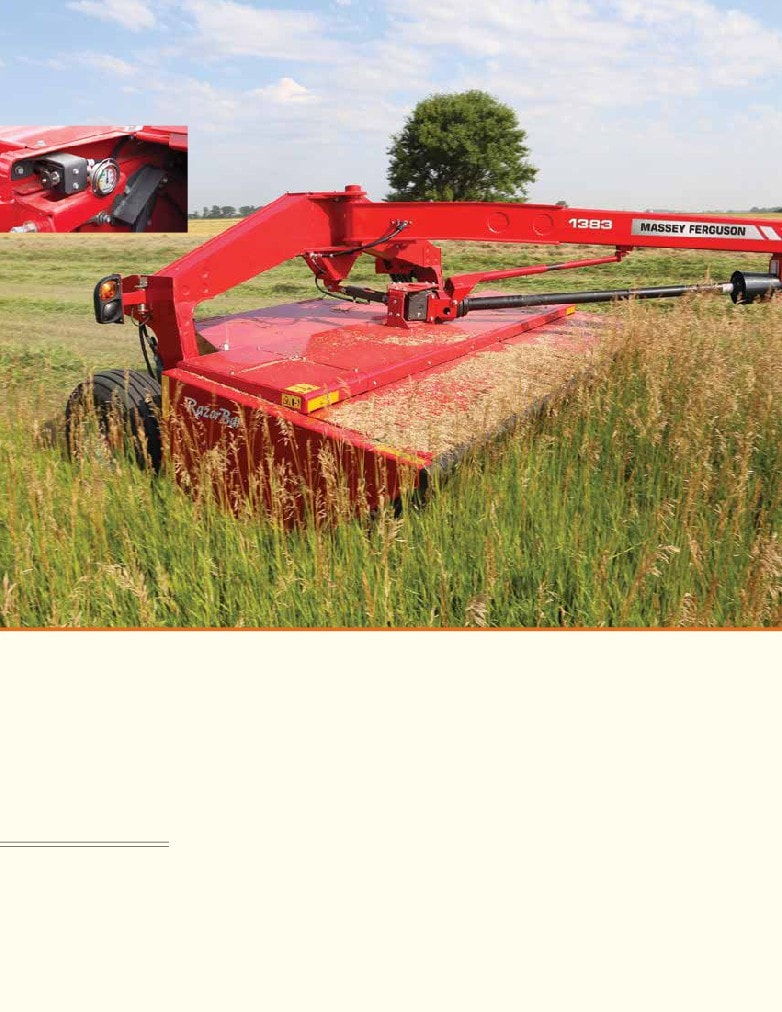

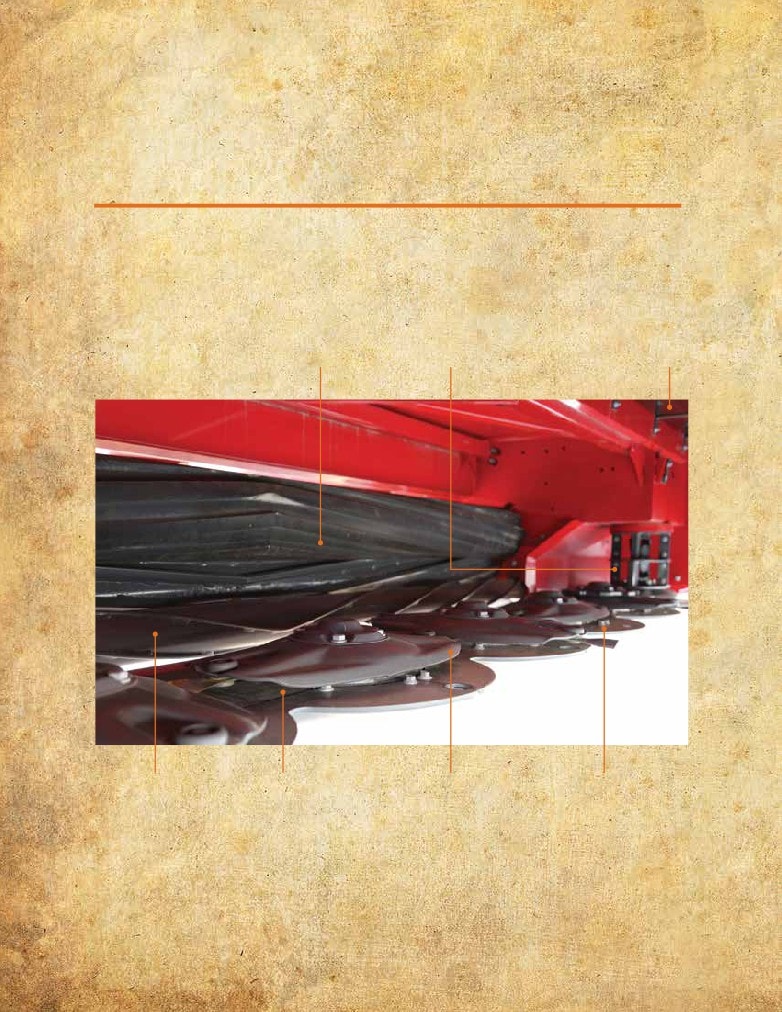

The Hesston 1300 Series

RazorBar™ cutterbar

redefines durability.

If you’re looking for commercial grade side-pull disc

mower conditioners, look no further than the new

Hesston 1300 Series with our patented RazorBar

header. Its modular, heavy-duty design literally

spells an end to costly downtime.

Not only do the wide-profile teeth offer increased

gear-to-gear contact, but the entire drivetrain is

Adjustable windrow-forming

designed to handle maximum load all the time.

shields and a swathboard

allow you to tailor the windrow

An industry exclusive, the RazorBar header’s sealed

size and shape — as narrow as

bearings don’t require constant lubrication, no matter

40 inches — to your baling or

the slope of the terrain. Should the worst happen, the

harvesting needs.

gear spindle will shear outside the cutterbed, keeping

contamination away from the gears.

Other unique features of the RazorBar include:

EXCLUSIVE THREE-YEAR

RAZORGUARD WARRANTY

Warranty provides an

n High-carbon steel knives available in a choice of

additional two-year parts-only

degrees and bevels to match crop and field conditions.

warranty on top of the one- year

warranty for the machine.

n Counter-rotating discs with increased overlap that

Valid on mowers equipped with

provide improved cut quality while minimizing

RazorBar heads including the

crop streaking.

1359 model.

n Sloping disc hub mounts to help reduce debris and

twine buildup.

n Ductile cast-iron module housings machined for

perfect alignment and maximum durability.

n Built-in rock guards to provide structural support for

the cutterbar.

n Swivel gearbox and support arm that move with the

tongue to keep the driveline components in-line for

exceptionally smooth operation.

The RazorBar cutterbar’s modular design

allows each gear assembly and adjacent idler

gear to be individually removed without

disassembly of the cutterbar. The spur gear

design also provides a thinner profile,

allowing closer cutting with less scalping.

The internal spur gears offer high tooth-to-tooth

The high-clearance mainframe provides an

contact at all times to transfer high torque and

exceptional header lift height of 20 inches for

seamless power throughout the entire cutterbar.

better clearance over headland windrows. The

added height also allows the header to be easily

carried over obstacles, ditches and waterways.

Hesston.com | 7

HYDRAULIC CONDITIONING

ROLL TENSION on the 1383 &

1386. This is the first pull-type

design to have this system.

Disc mower speed meets center-pivot maneuverability.

A constant-velocity,

Slice through tough, tangled crops at speeds that

windrows, as well as ditches and waterways. Everything

mechanical driveline,

can only be attained with a rotary disc machine and

about this rugged, high capacity mower series is designed

coupled with your choice

maneuverability that only Hesston 1300 Series

to give commercial operators reliable, trouble-free haying

of a three-point or drawbar-

center-pivot models can provide. Choose the Hesston

performance season after season.

mounted swivel hitch,

1383 with its 13-foot cutting width, or step up to the

provides smooth power

Hesston 1386 with its 16-foot cutterbed.

The herringbone steel-on-steel or rubber-on-steel

transfer and turn-on-a-

conditioner rolls are powered by individual roll-drive

dime maneuverability.

Both models feature industry-exclusive hydraulic

shafts and an oil-lubricated drive gear case that reduces

conditioning roll tension which delivers consistent

roll drive maintenance.

quality hay, resulting in a top-quality, high-nutrient crop

that’s more palatable and more valuable. A heavy duty

Add it all up and you’ve got unmatched reliability

rear arch frame provides exceptional support and header

coupled with performance that is synonymous with the

lift of 18 inches for better clearance over headland

Hesston by Massey Ferguson name.

a

Performance always comes standard.

No matter which Hesston 1300 Series center-pivot disc mower conditioner you choose, you can be assured of quality

performance, thanks to impressive features you won’t find on most competitive machines.

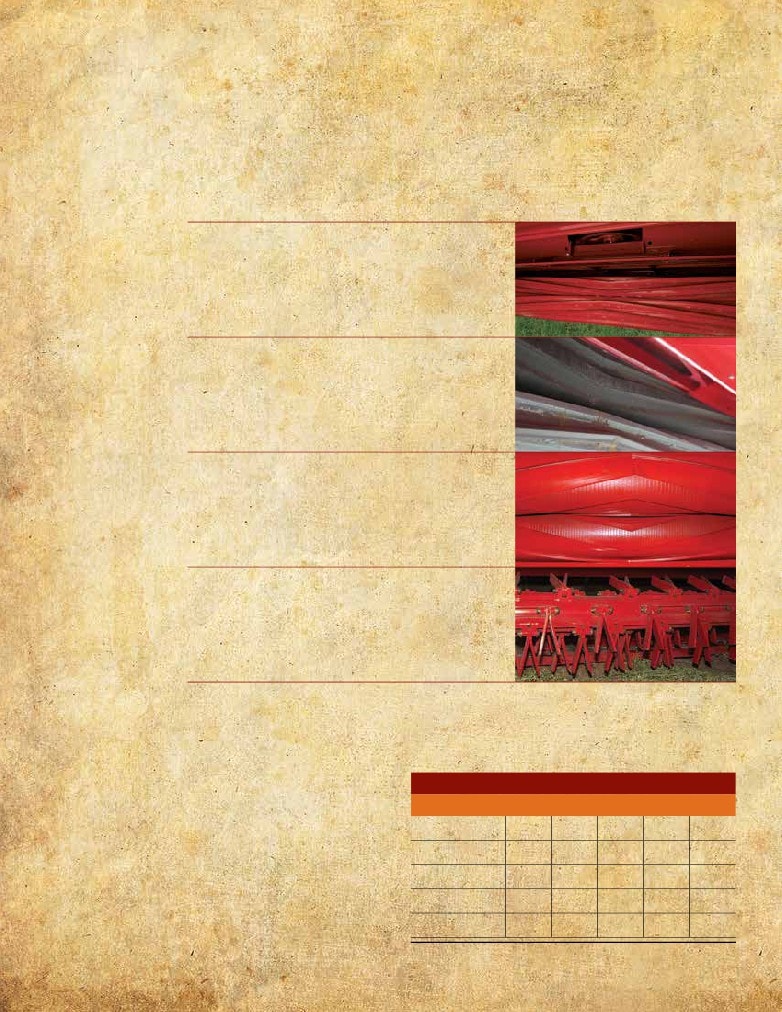

Herringbone

Cage crop conveyors

Top shield protector

conditioner rolls

Rotating cages at each

Tough, poly panels on the

Extra-wide, 110-inch

end of the cutterbed help

underside of the header

conditioner rolls increase

convey crop material to

shields absorb the impact

the capacity of the header

the conditioner rolls while

of rocks and debris to keep

and allow the crop to be

preventing crop material

the sheet metal from being

distributed into a thinner

from wrapping on the

dented, scraped or

mat for more uniform

cutterbed driveshaft.

exposed to rust.

conditioning.

Turbulence reduction roll

Pre-lubricated,

Cutterbar

Rock guards

A turbulence reduction

sealed bearings

High tooth-to-tooth

Smooth-profile rock

roll, or helper roll, located

Pre-lubricated bearings

contact at all times allows

guards, integrated into

between the conditioner

provide a longer life, while

the cutterbar to evenly

the cutterbed, reduce

rolls and the cutterbed

substantially reducing

transfer power throughout

mud build-up, while

allows the conditioner

maintenance, compared

the cutterbar and help

protecting the disc and

rolls to be positioned

to cutterbeds that require

protect the cutterbar

knives from rocks and

farther back, improving

regular oil checks.

against foreign objects.

other obstructions.

performance in light crops

and assisting crop flow in

dense, heavier crop.

Hesston.com | 9

Conditioner options to match every need.

Choose the unique conditioner options that meet your specific crop and operating conditions. Regardless of model,

the extra-wide width ensures thorough, uniform conditioning that helps increase the total value of your crop.

Steel-on-Steel Rolls

Designed to meet the needs of custom and commercial operators,

steel-on-steel rolls feature a herringbone pattern that provides long-

lasting durability while evenly distributing crop material across the

full width of the rolls. They’re also the best option for alfalfa, since

they crimp the stems, for faster drying, while maintaining leaf quality.

Rubber-on-Steel Rolls

These rubber-on-steel conditioner rolls are fully engaged to crimp

plant stems along their entire length so stems dry at the same speed

as the leaves.

Rubber-on-Rubber Rolls

Featuring a herringbone tread pattern that helps improve windrow

formation, our rubber-on-rubber rolls are designed for those who

prefer more crushing-type conditioning action. The shallow lugs

minimize leaf damage compared to deep-lug urethane rollers that

tend to scuff the crop and damage the leaves.

Spoke Conditioner

A good choice for grass hay, the spoke conditioner uses 74 free-

swinging spokes, spinning at 1,030 RPM, to effectively condition

the crop and force it to rub against the conditioning panel. This,

in turn, scuffs the waxy coating from the plant stems, allowing

them to dry faster.

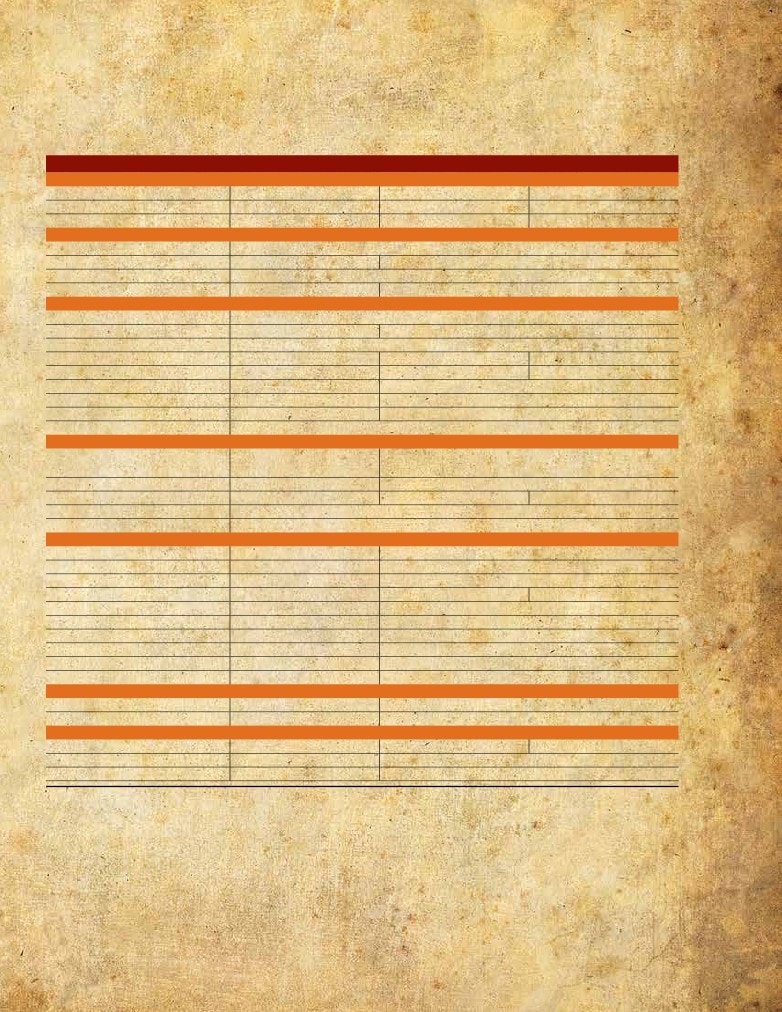

CONDITIONER OPTIONS

MODEL

1359

1363

1366

1383

1386

Rubber-on-Steel

I

I

Steel-on-Steel

I

I

I

I

I

Rubber-on-Rubber

I

I

I

Spoke Conditioner

I

I

Less Conditioner

I

I

Customized performance.

Although Hesston 1300 Series disc mower conditioners

are built to handle nearly any type of material or challenge,

certain situations call for additional equipment. That's why

we offer all the options you could ever need to match your

specific cropping program. These include:

n Topping skids and/or skid shoes for additional

ground clearance.

n A hydraulic header tilt on select models for on-the-go

cutterbar angle adjustment.

n Filler pan kit (1383-1386 only) for enhanced

performance in tall stalk or biomass crops.

Hesston.com | 11

Invest wisely.

Hesston by Massey Ferguson has built a worldwide following by building equipment that lasts. We understand

that buying any piece of equipment represents an investment of your hard-earned dollars. That’s why we go

the extra mile right from the start, so our machines go the extra mile for years to come. It’s a tradition we’ve

maintained for 70 years.

LOW-RATE, FLEXIBLE FINANCING

Your dealer and AGCO Finance offer attractive financing to

make sure a new Hesston 1300 Series disc mower conditioner

will fit your operating budget. Extremely competitive rates and

terms make it easy to buy or lease.

A great deal includes a great dealer.

If you’re like most farmers, when you find the perfect piece of equipment, it becomes almost like part of your family.

And when you buy a Hesston 1300 Series disc mower conditioner, you instantly become part of ours. Our network

of dealers knows what it takes to put up quality hay, and they have the knowledge to match the right mower or mower

conditioner with the right producer. They’ll advise and support you throughout the selection process, the buying

process, through operation, maintenance and beyond. Because our dealers share your passion for farming, they’re

happy to share their knowledge to keep you working happily and productively. After all, you’re family. And there’s

nothing we wouldn’t do for family.

All-inclusive warranty

AGCO Parts

Even our warranty is high-performance. The one-year/

Genuine Hesston by Massey Ferguson replacement

EXCLUSIVE THREE-YEAR

unlimited-hour, all-inclusive warranty on parts and labor

parts are manufactured to the same high standards of

RAZORGUARD WARRANTY

is one of the best in the business. More importantly, it’s

quality and dependability as the original part used on the

Warranty provides an

backed by dealers who understand how to help you make

assembly line. Using original equipment parts will help

additional two-year parts-only

the most of it.

keep your mower or mower conditioner running like new

warranty on top of the one-year

for a long time.

warranty for the the machine.

Valid on mowers equipped with

RazorBar heads including the

1359 model.

Questions? Go to Hesston.com

AGCO Answers

Our website opens the door to all sorts of technical

(877) 525-4384 | agcoanswers@agcocorp.com

information and product specifications. If you can’t

At AGCO, customer care isn’t just a department — it’s a

find what you’re looking for, click on “contact us” and

commitment. Contact us with your questions. We’ll do

we’ll provide you with access to folks who can get you

our best to answer them promptly, or put you in touch

all the answers.

with someone who can.

Build & quote

Join our conversation.

Easily configure, price and compare

Engage.

equipment using our “Build my

facebook.com/AGCOcorp

Massey Ferguson” tool. You can sort

through available product options and

The AGCO Farm Life

Follow.

design machines to fit your unique needs.

magazine is our exclusive

twitter.com/AGCOcorp

Visit masseyferguson.com/buildmymassey

publication that offers

Watch.

farming news, interviews

The doors are always open at ShopMassey.com

youtube.com/AGCOcorp

and insights — for and by

You’ll find all sorts of unique

Hesston Hay YouTube channel

farmers like you. Visit us

Massey Ferguson wearables

online at myfarmlife.com.

&

Learn.

and gifts for the entire family.

blog.AGCOcorp.com

Plus some good old-fashioned

bargains, too.

Hesston.com | 13

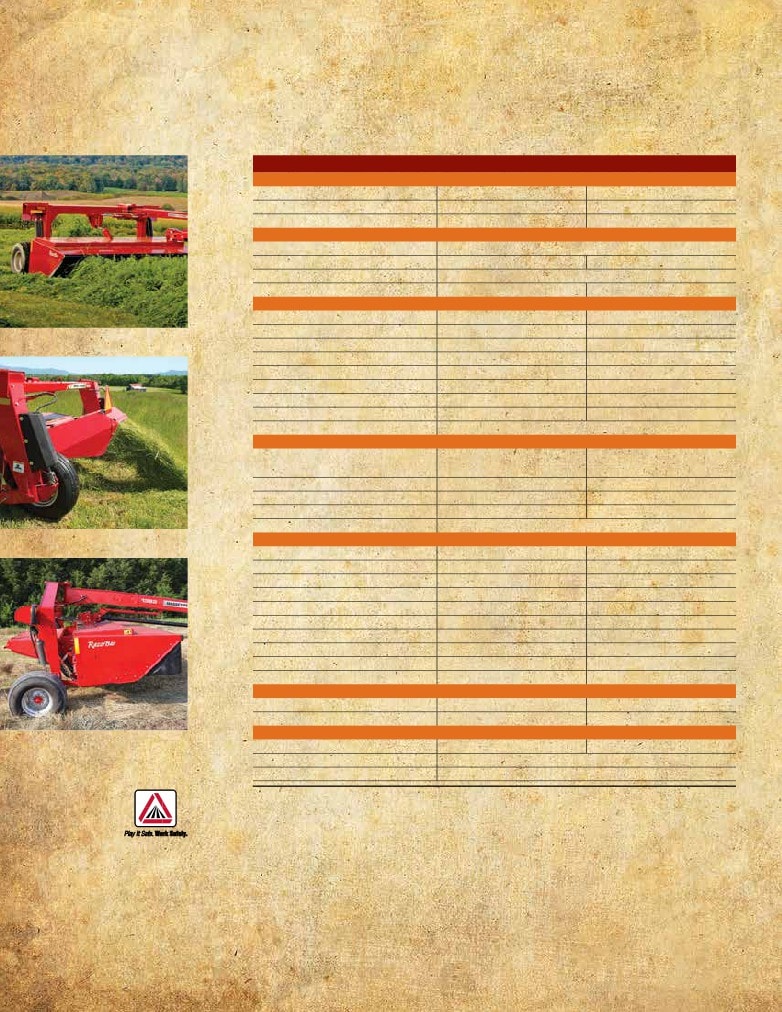

DISC MOWER CONDITIONER MODEL

1359

1363

Dimensions and Weights

Width of cut: ft. (m)

9.3

(2.8)

9.8

(3.0)

Overall width: ft. (m)

11 (3.3)

9.8

(3.0)

Weight: lbs. (kg.)

3,240 (1,469)

4,520 (2,050)

Mainframe and Header

Pull/Pivot

Side

Header lift range: in. (mm)

14 (356)

20 (510)

Header flotation

Radial and vertical with adjustable springs

Tires

9.5L x 14SL

1lL-15, 31 x 13.5-15 (opt)

Cutterbed

Cutterbar design

Modular component shaft drive

Spur gear- RazorBar

Cutting height: in. (mm)

1.8 to 3.0 (44 to 76)

0 to 8 (0 to 203)

Cutterbar operating range

0° to 8°

0° to 6°

Number of discs

7

6

Number of knives

14 (2 per disc)

12 (2 per disc)

Drive

Hex shaft from gearbox

3B powerband/gearbox

Disc speed: RPM

3,000

2,200

Knife tip speed: mph (km/hr)

175.8 (289)

162 (260.7)

Knives

Swingaway, reversible

Conditioner

Herringbone steel on steel or rubber

Roll type

Steel on steel or rubber on rubber

on steel, Tine conditioner

Length: in. (mm)

84 (2,134)

73 (1,854)

Speed: RPM

735

1,045

Roll separation

Hydraulic w/ header raise

NA

Drive

U-joint drivelines from gearbox

Diameter

Upr. Rubber-on-Steel roll: in. (mm)

NA

NA

Upr./lwr. Steel-on-Steel roll: in. (mm)

9.3 (235)

8.2 (209)

Rubber-on-Rubber roll: in. (mm)

9.5 (242)

8.0 (203)

Roll Speed: RPM

735

1,045

Length: in. (mm)

84 (2,131)

73 (1,854)

Less conditioner

NA

Opt.

Tine conditioner

NA

Opt.

Tine conditioner diameter: in. (mm)

NA

18 (462)

Number of double tines

NA

40

Tine speed: RPM

NA

1,056

Windrow Width

Windrow formation max: in. (mm)

72 (1,829)

73 (1,854)

Windrow formation min: in. (mm)

30 (72)

42 (1,067)

Tractor Requirements

Min. PTO horsepower (kW)

60 (45)

75 (56)

PTO speed

540

Hydraulics

1 DAV; 1 SAV

AGCO may at any time, and from time to time, for technical or other necessary reasons, modify any of the data, specifications or warranty of the

products described herein. Some equipment shown may be optional. Attention: Photographs in this publication may show protective shields and guards

open or removed for the purposes of illustration. Be certain all shields and guards are in place during operation.

DISC MOWER CONDITIONER MODEL

1366

1383

1386

Dimensions and Weights

Width of cut: ft. (m)

9.8

(3.0)

13 (3.9)

16 (4.8)

Overall width: ft. (m)

9.8

(3.0)

13.25 (4)

16.25

(4.9)

Weight: lbs. (kg.)

5,050 (2,291)

6,660 (3,020)

8,150 (3,697)

Mainframe and Header

Pull/Pivot

Center

Header lift range: in. (mm)

20 (510)

18 (457)

Header flotation

Radial and vertical with adjustable springs

Tires

1lL-15, 31 x 13.5-15 (Opt.)

31 x 13.5 x 15

Cutterbed

Cutterbar design

Spur gear- RazorBar

Cutting height: in. (mm)

0 to 8 (0 to 203)

1.25 to 3 (32 to 76)

Cutterbar operating range

0° to 6°

Number of discs

6

8

10

Number of knives

12 (2 per disc)

16 (2 per disc)

20 (2 per disc)

Drive

3B powerband/gearbox

2B banded belt

Disc speed: RPM

2,200

2,450

Knife tip speed: mph (km/hr)

163 (260.7)

178 (287)

Knives

Swingaway, reversible

Conditioner

Herringbone steel on steel or

Roll type

Herringbone steel-on-steel or rubber-on-steel

rubber on steel, Tine conditioner

Length: in. (mm)

73 (1,854)

109.8 (2,790)

Speed: RPM

1,045

1,037

1,215

Roll separation

NA

Drive

U-joint drivelines from gearbox

Diameter

Upr. Rubber-on-Steel roll: in. (mm)

NA

8 (203)

Upr./lwr. Steel-on-Steel roll: in. (mm)

8.2 (209)

7.7 (196)

Rubber-on-Rubber roll: in. (mm)

8.0 (203)

NA

Roll Speed: RPM

1,045

1,037

1,215

Length: in. (mm)

73 (1,854)

110 (2,794)

Less conditioner

Opt.

NA

Tine conditioner

Opt.

NA

Tine conditioner diameter: in. (mm)

18 (462)

NA

Number of double tines

40

NA

Tine speed: RPM

1,056

NA

Windrow Width

Windrow formation max: in. (mm)

73 (1,854)

96 (2,438)

Windrow formation min: in. (mm)

42 (1,067)

40 (1,016)

Tractor Requirements

Min. PTO: horsepower (kW)

75 (56)

100 (75)

120 (89)

PTO speed

540

1,000

Hydraulics

1 DAV; 1 SAV

2 DAV

Hesston.com | 15

We proudly support:

HESSTON, MASSEY FERGUSON and RAZORBAR are trademarks of AGCO.

©2015 AGCO Corporation. Massey Ferguson is a worldwide brand of AGCO. All rights reserved. HS15B003CR (12) 1 PD